LoopTester–TechnicalandOperationManual

8

Earth fault in the cable

Run singe test “Leakage to Earth”

again to confirm the presence earth

fault in the positive or negative

cable wire. In case of fault the

tester will display message “Earth

fault”.

Search the earth fault as inspect

the grounding components in the

cable line, corrupted shield of the

cable, etc.

You can also use and the Bisection

method described in item 4.5.3.

Too High resistance

According the result in the Auto

Cable Test menu run the single test

for:

“R+ Cable”

“R- Cable”

“R Earth Cable”

In case of unusual high resistance

found the tester will display

message “R+/R-/Re=Too High”.

The error message “Too High” is

displayed when the detected

resistance in the positive cable

wire (R+), negative cable wire (R-)

or earth cable (Re) is higher than

400 Ohm. In such cases, it is

recommended to check the cable

and the joint connections

(terminals, base contacts). Check

also the cable length – it might be

too long.

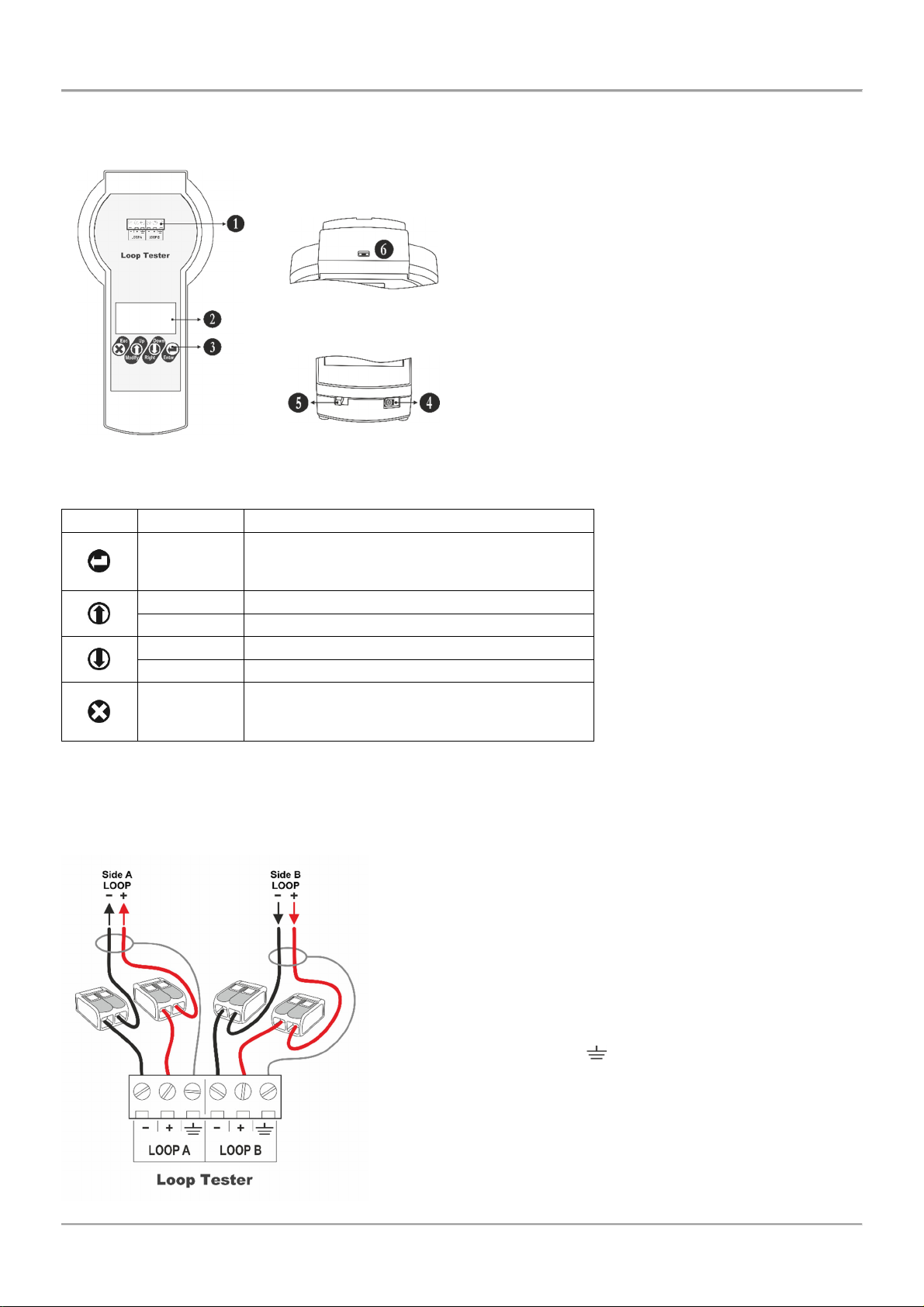

4.5 Perform Loop Tests

This is a menu for performing test of the loop and the connected devices. It is recommended to run first the “Loop

state” automatic test for reviewing the general state of the loop and a list of the connected devices. The general

review will help you at the beginning to orientate for current faults, possible breaks or short-circuits in the loop, the

number of connected devices and troubles with them.

4.5.1 Loop State

Cable tests

Loop Tests

Addressing

Language

Loop State

Loop Tools

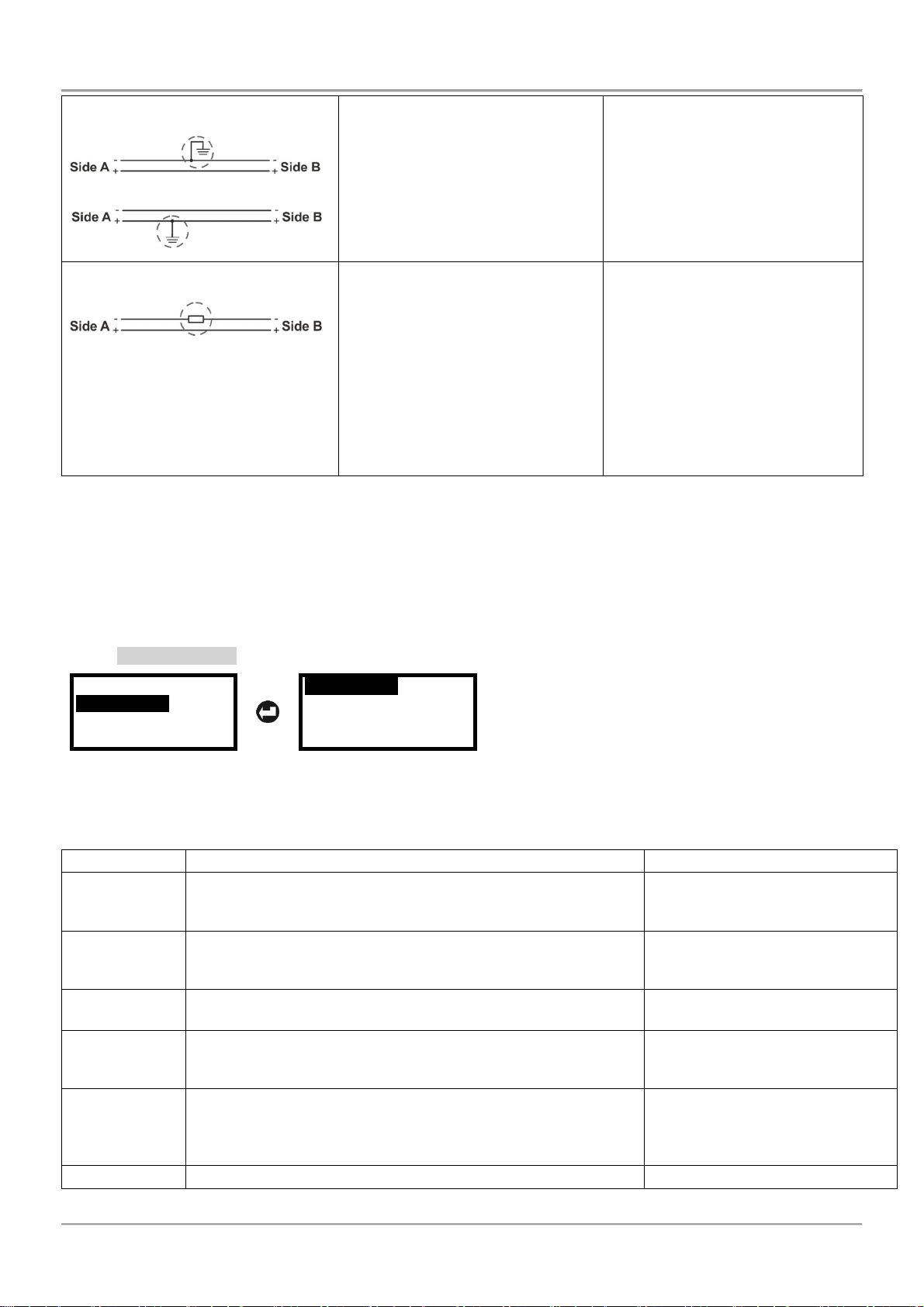

Select “Loop State” menu and press ENTER. The message “Please wait” and a process bar are shown during

analysing the current loop state. The time for reading data can vary according the length and the number of

connected devices.

The general information is displayed as a list with short messages for the state and can be reviewed (scrolling

up/down) with arrow buttons:

Parameter Description State Messages

Short Side A

Shows the presence of short circuit at Loop Side A. In case of

fault “Yes” message, you can perform a detailed search using

menu “Loop Tools” – “Short / Break” (see item 4.5.5).

None – No fault

Yes – Short circuit detected at

side A.

Short Side B

Shows the presence of short circuit at Loop Side B. In case of

fault “Yes” message, you can perform a detailed search using

menu “Loop Tools” – “Short / Break” (see item 4.5.5).

None – No fault

Yes – Short circuit detected at

side B.

Earth Fault Shows the presence of earth fault in the loop. None – No fault

Yes – Earth fault detected.

Loop Break

Shows the presence of break in the loop. In case of fault “Yes”

message, you can perform a detailed search using menu “Loop

Tools” – “Short / Break” (see item 4.5.5).

None – No fault

Yes – Loop break detected.

No addr. Dev.

Shows the presence of devices with no set address in the loop.

Note: A possible reason for presence of devices with no set

address is performing the Loop State test for an unaddressed

loop.

None – No unaddressed devices

XXX – Number of found

unaddressed devices

Dbl. address Shows the presence of devices with double address in the loop. None – No double addresses