7596004CM - Manuale EASYBLUE COMENDA ENG ok - 2 -

INDEX

1GENERAL INFORMATIONS...........................................................................................................................4

1.1. MANUFACTURER / ASSISTANCE .......................................................................................... 4

1.2. CERTIFICATION ............................................................................................................ 4

1.3. PURPOSE OF THE MANUAL AND ITS CONTENTS........................................................................ 4

1.4 CARE AND STORAGE OF THE MANUAL .................................................................................. 4

2. CHARACTERISTICS OF THE DEVICE ..........................................................................................................5

2.1. RECOMMENDED USE ....................................................................................................... 5

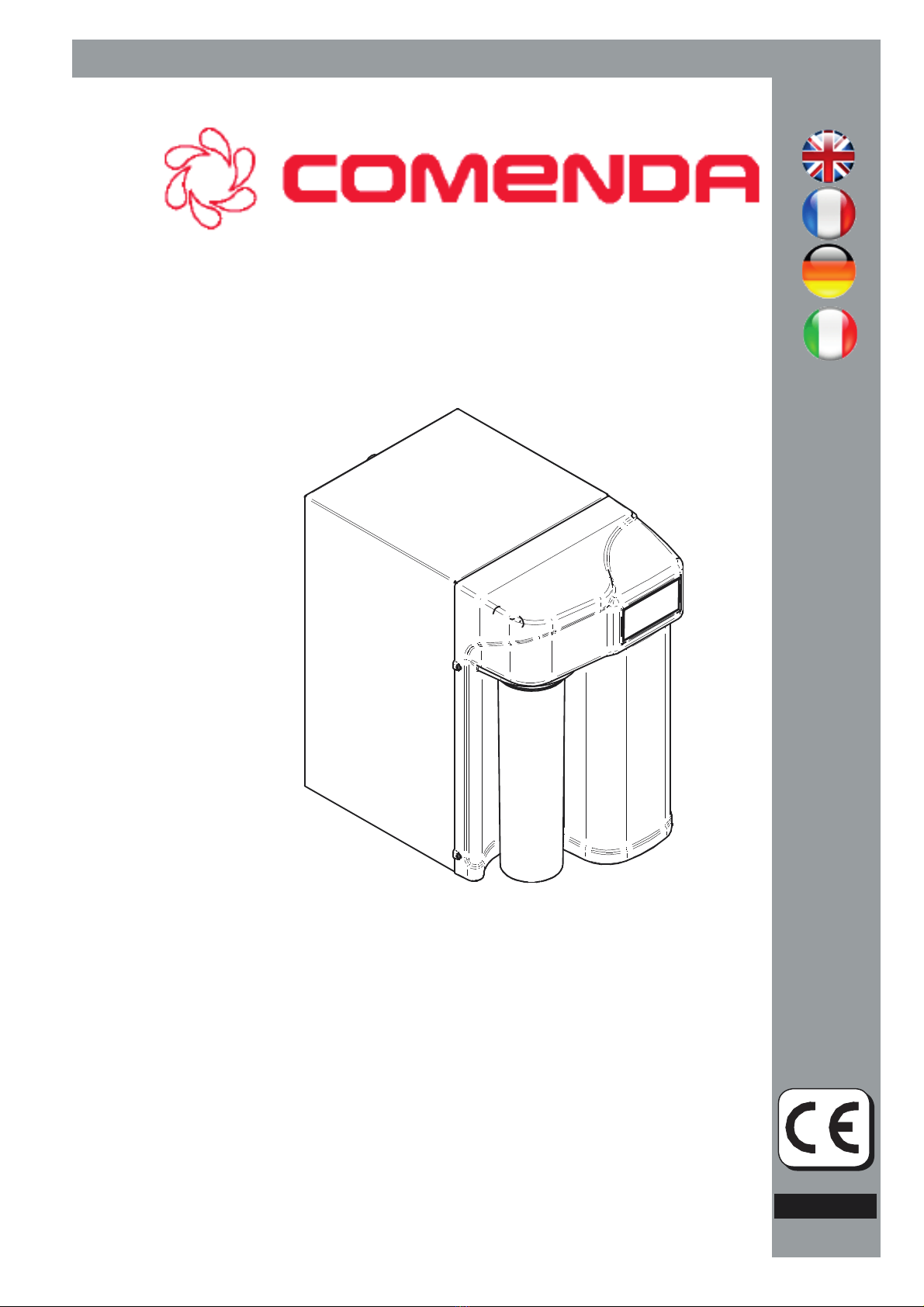

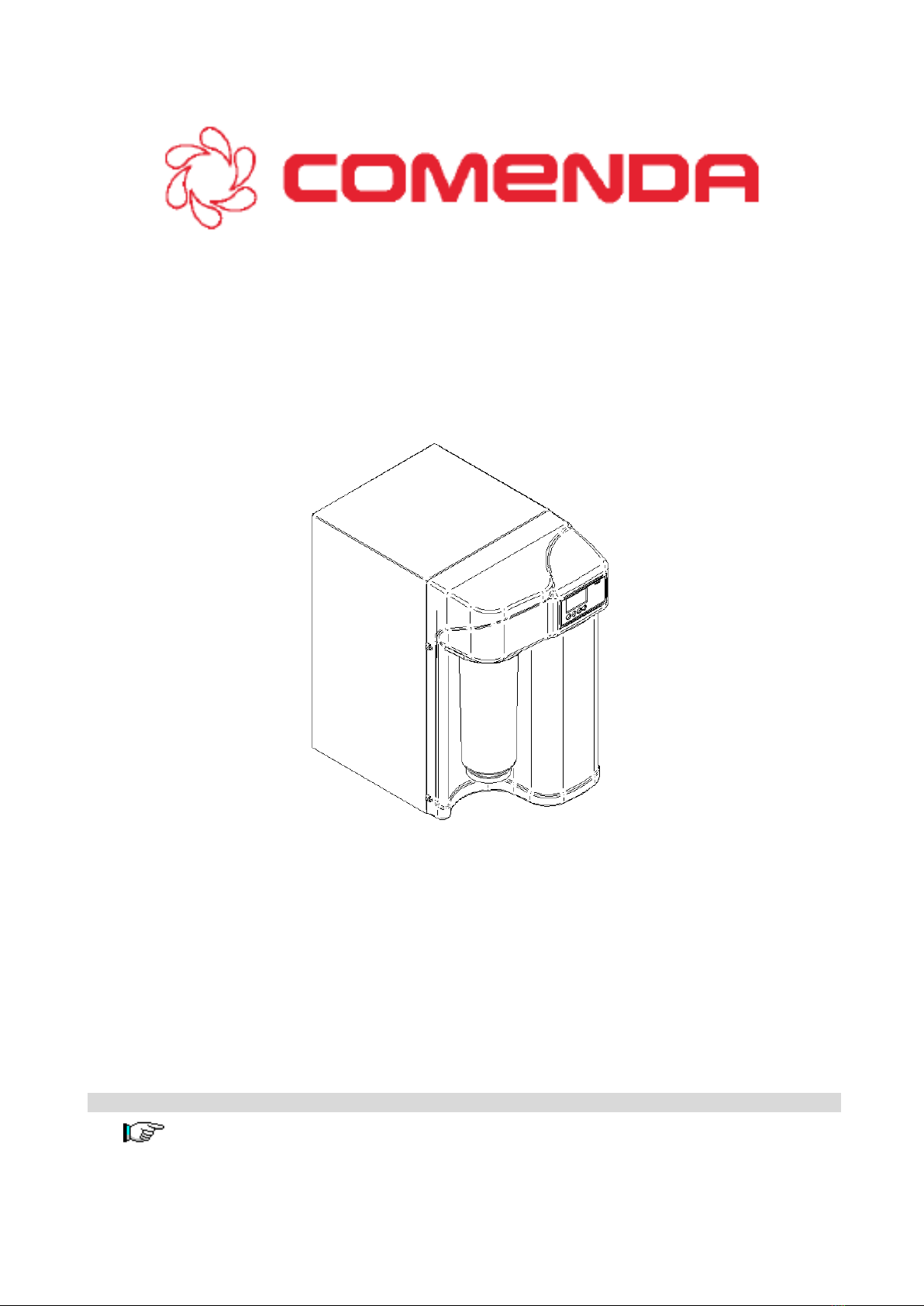

2.2 PARTS THAT MAKE UP THE MACHINE ................................................................................... 5

2.2 COMPONENTS .............................................................................................................. 6

2.3 DESCRIPTION............................................................................................................... 6

2.4 TECHNICAL SPECIFICATIONS ............................................................................................. 8

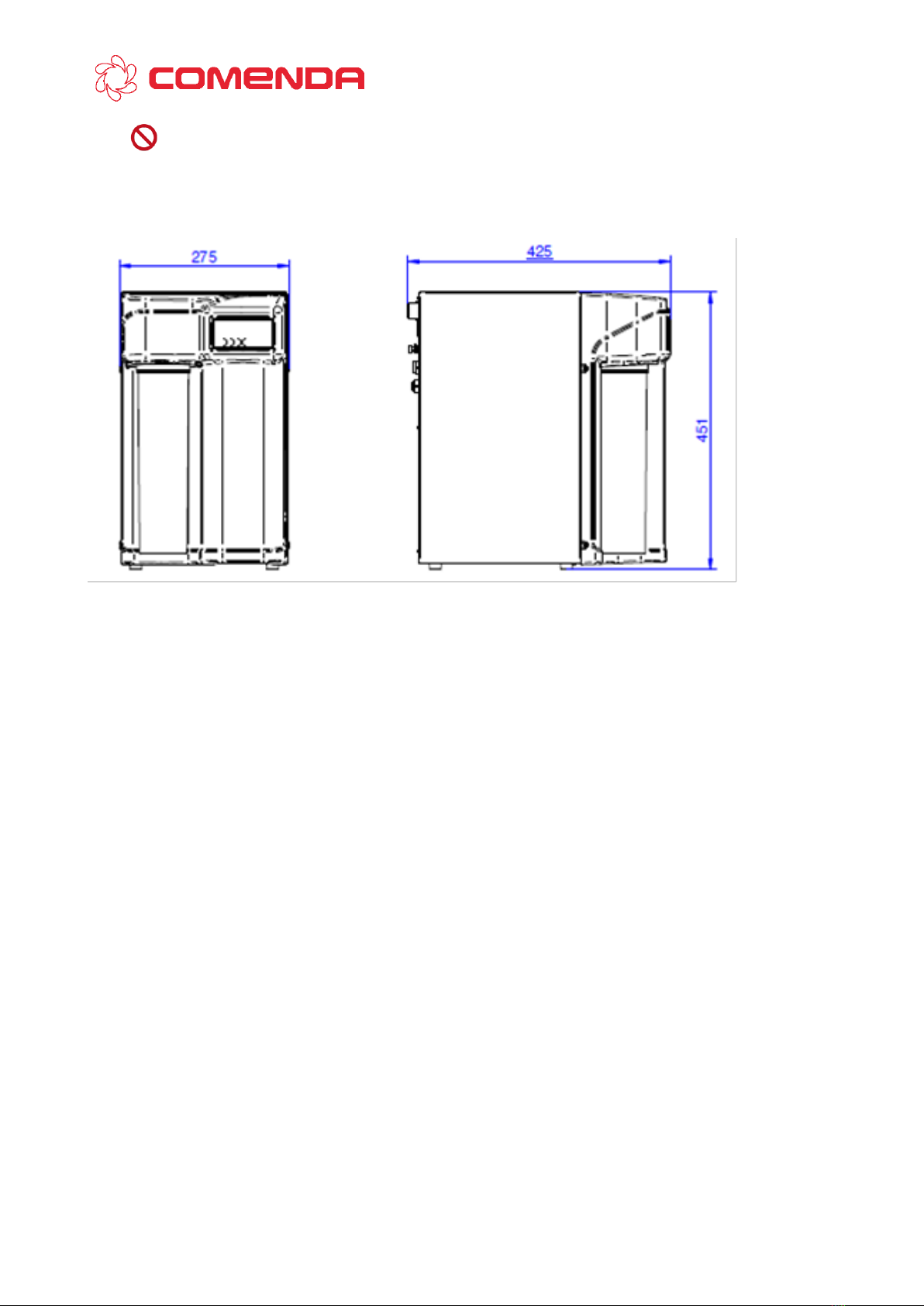

2.5. GENERAL DIMENSIONS .................................................................................................... 9

3INSTALLATION.............................................................................................................................................10

3.1 INSTALLING THE WATER TAP ........................................................................................... 11

3.2 INSTALLING THE DRAIN BRACKET ...................................................................................... 12

3.3 TAP INSTALLATION ....................................................................................................... 13

4FUNCTIONING.......................................................................ERRORE. IL SEGNALIBRO NON È DEFINITO.

4.1 FIRST START UP ................................................................ Errore. Il segnalibro non è definito.

4.2 NORMAL USE .................................................................... Errore. Il segnalibro non è definito.

4.3 INACTIVITY ...................................................................... Errore. Il segnalibro non è definito.

4.4 ELECTRONIC BOARD OPERATING ............................................. Errore. Il segnalibro non è definito.

5ORDINARY MAINTENANCE.........................................................................................................................19

5.1 QUALIFICATION OF MAINTENANCE PERSONNEL....................................................................... 19

5.2 RESPONSIBILITIES OF MAINTENANCE PERSONNEL .................................................................... 19

5.3 REPLACING FILTER CARTRIDGE ......................................................................................... 20

5.4 VERIFICATION OF THE SETTING ........................................................................................ 21

5.5 CLEANING CONDUCTIVITY PROBE CONNECTORS ..................................................................... 21

5.6 CLEANING SOLENOID VALVES FILTER .................................................................................. 22

5.7 MACHINE SANITATION.................................................................................................... 22

6EXTRAORDINARY MAINTENANCE ............................................................................................................23

6.1 ELECTRONIC BOARD AND DISPLAY REPLACEMENT.................................................................... 23

6.2 PROTECTION FUSE REPLACEMENT...................................................................................... 23

6.3 VANE PUMP REPLACEMENT.............................................................................................. 24

6.4 CHECK/REPLACEMENT OF OSMOTIC MEMBRANES .................................................................... 25

7TROUBLE-SHOOTING .................................................................................................................................26

8DISPOSAL.....................................................................................................................................................28

ATTACHMENT I –UE DECLARATION ...........................................................................................................................29

ATTACHMENT II –SPARE PARTS AND ACCESSORIES LIST MINI-BLUE.................................................................30

ALLEGATO III - ETICHETTATURA UE ...........................................................................................................................30