Instruction sheet

–

Safety limit switch with separate actuator

The COMEPI safety limit switches are devices designed and made in compliance

with the international IEC regulations and the EN European standards. They

can be used for monitoring guards on industrial machines and for building

safety systems in compliance with standard EN ISO 14119. Being a protection

equipment for operators, its incorrect installation or tampering can damage

people, even seriously.

The device installation must be carried out according to

the regulations in force by authorized staff only. Make sure the switch works

properly before starting the machine and periodically check the correct

operation of the equipment.

Installation precautions

Before starting the machine, check the proper operation of the safety system.

Periodically check the correct operation of the device.

The device installation must be carried out by authorized and qualified staff

only.

The device use must be limited to the applications meeting the regulations

requirements.

The device installation and the safety system design must be carried out only

by people knowing the regulations in force.

The device installation and the safety system design must be carried out in

compliance with the regulations in force.

In case of doubts or special applications, please contact COMEPI Technical

Support.

Do not install in dusty or dirty places.

During installation and operation, it is fundamental to prevent dust and dirt

from entering the opening when the start key is not inserted.

Before any painting operation, cover the opening and the identification label.

Do not install in places where there are flammable dusts or gases.

Do not install in places with strong vibrations; impacts and vibrations can

prevent the switch correct operation.

Use only proper actuators supplied by COMEPI, suitable for the model used;

otherwise safety could be void.

Install the actuator in a suitable way, so that it does not harm the operator

when the door is open.

If the microswitch is damaged or worn, replace the whole device to ensure

safety.

If the actuator is damaged or worn, replace it.

Replace the equipment after exceeding the mechanical durability limit.

During wiring, keep load under the value of the use category.

Check that safety contacts are connected to a protection fuse.

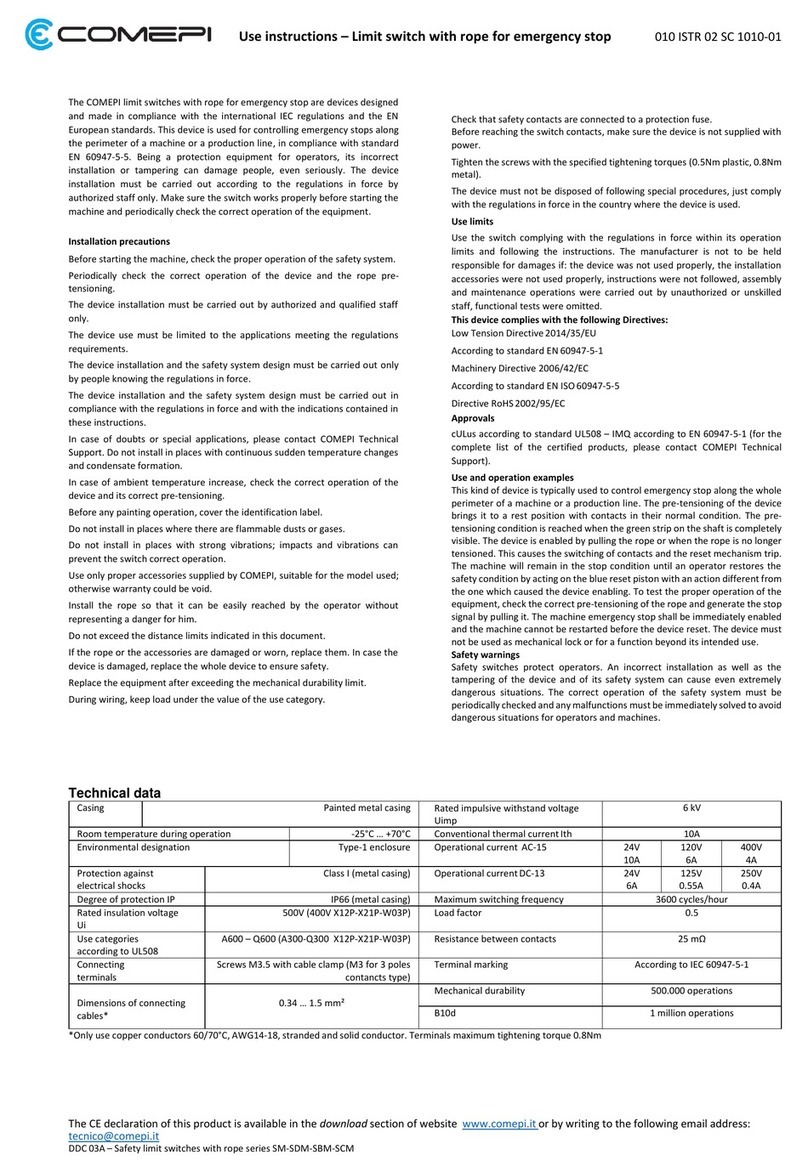

Technical data

Before reaching the switch contacts, make sure the device is not supplied with

power.

Tighten the screws with the specified tightening torques (0.5Nm plastic, 0.8Nm metal).

The device must not be disposed of following special procedures, just comply

with the regulations in force in the country where the device is used.

Use limits

Use the switch complying with the regulations in force within its operation

limits. The manufacturer is not to be held responsible for damages if: the device

was not used properly, instructions were not followed, assembly and

maintenance operations were carried out by unauthorized or unskilled staff.

This device complies with the following Directives:

Low Voltage Directive 2014/35/EU

According to standard EN 60947-5-1

Machinery Directive 2006/42/EC

According to standard EN ISO 14119

Directive RoHS 2002/95/EC

Approvals

cULus according to standard UL508 – IMQ according to EN 60947-5-1 (for the

complete list of the certified products, please contact COMEPI Technical

Support).

Use and operation examples

This kind of device is typically used to monitor the safety guards on industrial

machines. When the guard is closed, the microswitch is in the normal operation

condition, while when the guard is open, the signal controlling the machine stop

due to dangerous situation is produced. A single device cannot be used to

ensure safety when the guard protects the perimeter of machines for which

dangerous conditions may last a certain time after generating the stop signal.

Moreover, this device cannot be used as emergency stop device. To test the

proper operation of the equipment, check the correct insertion of the actuator

into the head opening and close the guard starting the machine. When opening

the guard, the machine stop signal will have to be produced. The machine

restart must be impossible while the actuator is not inserted in the device

opening. The device must not be used as mechanical lock and it is necessary to

avoid actuator impacts on the head, due to misalignment of components.

Safety warnings

Safety switches protect operators. An incorrect installation as well as the

tampering of the device and of its safety system can cause even extremely

dangerous situations. Never bypass or tamper with the device. In order to avoid

any tampering attempt, it is advisable for the installer to mount the device in a

place that cannot be easily reached by unauthorized staff, even using physical

barriers or other means to make tampering difficult.

Technopolymer or painted metal casing

Rated impulsive withstand voltage Uimp

Air temperature during operation

Conventional thermal current Ith

Environmental designation

Operational current AC-15

electrical shocks

casing)

(thermoplastic

casing)

Operational current DC-13

6A

0.55A

0.4A

Maximum switching frequency

Rated insulation

voltage Ui

500V (400V Z02-X12P-X21P-W03P)

according to

UL508

A600 – Q600 (A300-Q300 X12P-X21P-W03P)

Resistance between contacts

Screws M3.5 with cable clamp (M3 for 3 poles

contacts type)

According to IEC 60947-5-1

Dimensions of

connecting

cables*

0.34 … 1.5 mm²

*Only use copper conductors 60/70°C, AWG14-18, stranded and solid conductor. Terminals maximum tightening torque 0.8Nm

The CE declaration of this product is available in the download section of website www.comepi.it or by writing to the following email address:

DDC 03 – Safety limit switches series SP-SM-SDP-SDM-SBP-SBM-SCM-SFP

KEY 4 KEY 5 / 45 KEY 6 / 46 KEY 7