First issue 10/14 Release A10/14

PGRF 2/9

INDEX

SYMBOLS USED

SAFETY SHOES

Safety shoes must be worn by all autorized people to

work on the reduction gear

SAFETY GLOVE

Safety glove must be worn by all autorized people to

work on the reduction gear

SAFETY GLASSES

Safety glasses must be worn by all autorized people to

work on the reduction gear

OBLIGATION

Operation to be observed

DANGER

Be careful of hanging loads

PROHIBITION

Do not work with machines in movement

PROTECTIVE CLOTHING

Protective clothing must always be worn by personnel

authorized to work with reduction gears.

WARNING

Operation must be carried out with extreme care with

personal injury if proper procedures are not followed

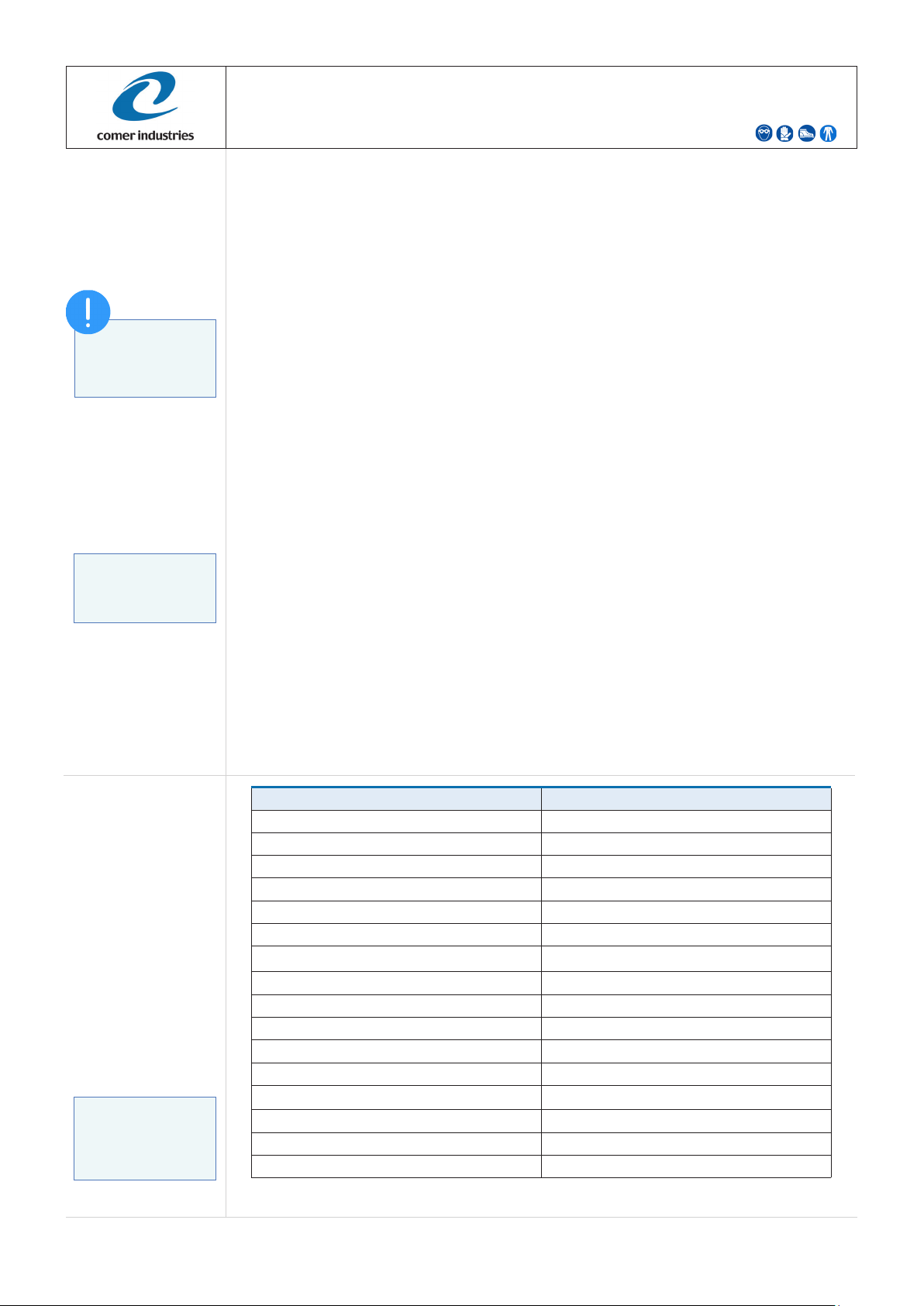

GENERAL INFORMATION....................................................................................................................................................................................... 3

GEARBOX UNIT IDENTIFICATION ............................................................................................................................................................. 3

RISKS AND PRECAUTIONS........................................................................................................................................................................ 3

TRANSFER AND STORAGE ....................................................................................................................................................................... 3

HANDLING ................................................................................................................................................................................................... 3

PRODUCT DISPOSAL ................................................................................................................................................................................. 3

GEARBOX UNIT........................................................................................................................................................................................... 4

INTENDED USE AND LIMITATIONS............................................................................................................................................................ 4

LUBRICANT ................................................................................................................................................................................................. 4

ORDINARY MAINTENANCE.................................................................................................................................................................................... 5

MAINTENANCE............................................................................................................................................................................................ 5

MAINTENANCE INTERVALS ....................................................................................................................................................................... 5

OIL REPLACEMENT PROCEDURE ........................................................................................................................................................................ 6

OIL DRAINING.............................................................................................................................................................................................. 6

OIL TOPPING OFF....................................................................................................................................................................................... 6

OIL FILLING.................................................................................................................................................................................................. 6

INSTALLATION AND START UP.................................................................................................................................................................. 7

PRELIMINARY CHECKS AND INSTALLATION ........................................................................................................................................... 7

START UP .................................................................................................................................................................................................... 7

MALFUNCTIONING AND FAILURE ............................................................................................................................................................. 7

FUNCTIONING INTERRUPTION.............................................................................................................................................................................. 7

TROUBLESHOOTING.............................................................................................................................................................................................. 8

TORQUE WRENCH SETTING ................................................................................................................................................................................. 9

This manual :

• provides all information about ordinary maintenance, installation and use for this unit,

• must be read and understood by the authorized people/operators before any kind of intervention,

• must be kept handy, in a safe place and must always be clear and legible for future reference whenever needed.