508107-01Issue 2041

Page 9 of 55

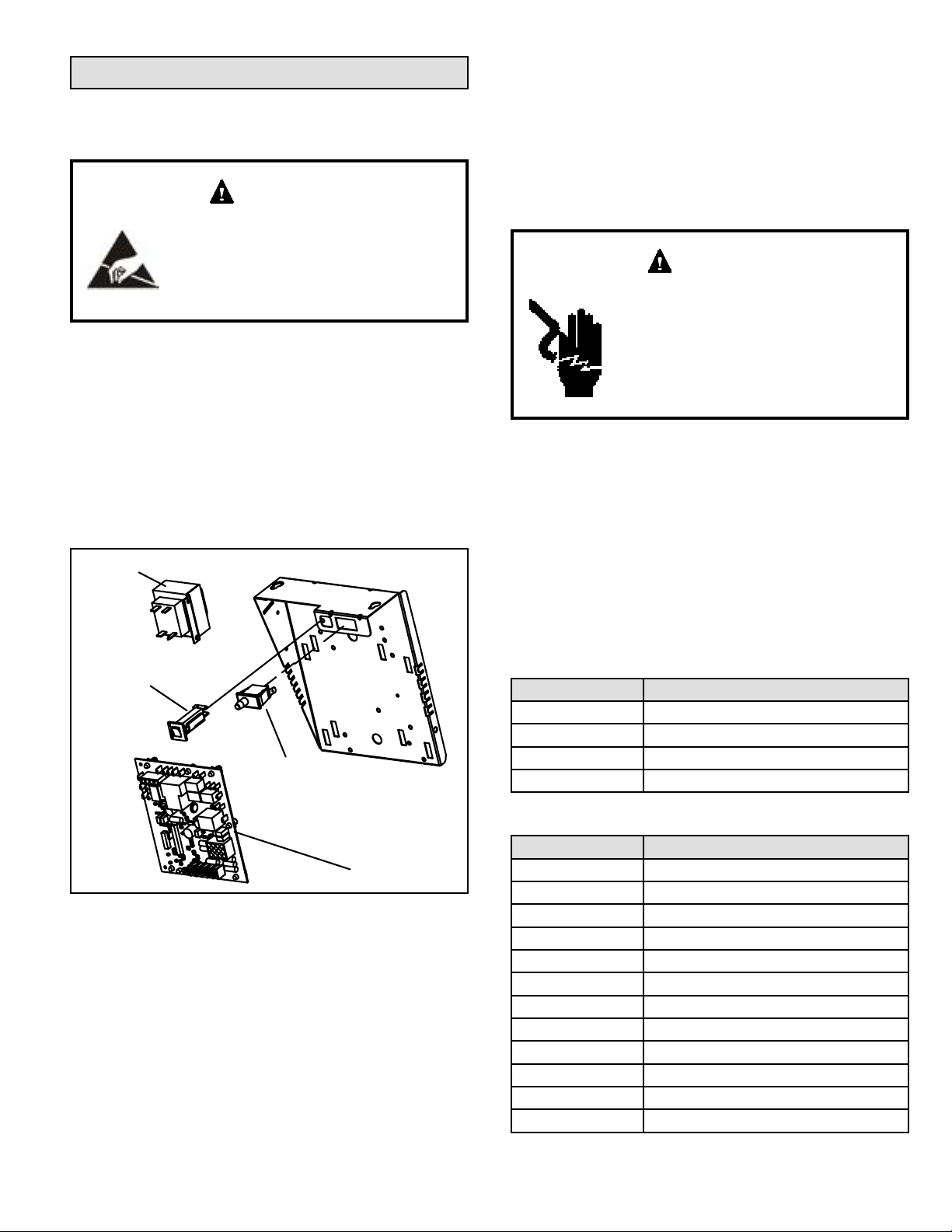

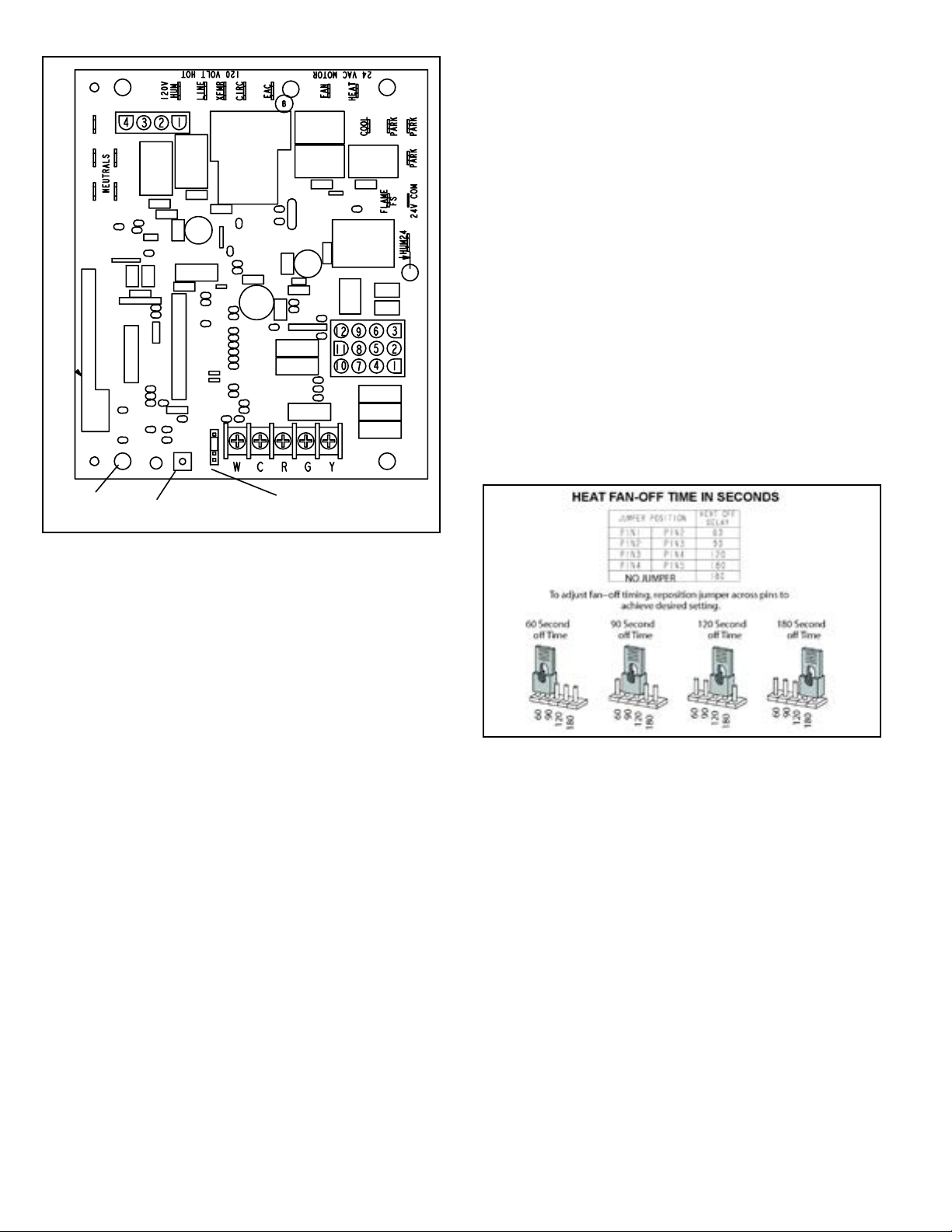

Figure 3. Integrated Control

(Automatic Hot Surface Ignition System)

BLOWER OFF DELAY

RED LED RECALL BUTTON

Electronic Ignition

On a call for heat the integrated control monitors the

combustion air inducer pressure switch. The control board

will not begin the heating cycle if the pressure switch is

closed (by-passed). Once the pressure switch is determined

to be open, the combustion air inducer is energized. When

the dierential in the pressure switch is great enough, the

pressure switch closes and a 15-second pre-purge begins.

If the pressure switch is not proven within 2-1/2 minutes,

the integrated control goes into Watchguard-Pressure

Switch mode for a 5-minute re-set period.

After the 15-second pre-purge period, the ignitor warms

up for 20 seconds during which the gas valve opens at

19 seconds for a 4-second trial for ignition. The ignitor

remains energized for the rst 3 seconds during the 4

second trial. If ignition is not proved during the 4-second

period, the integrated control will try four more times with

an inter purge and warm-up time between trials of 35

seconds. After a total of ve trials for ignition (including the

initial trial), the integrated control goes into Watchguard-

Flame Failure mode. After a 60-minute reset period, the

integrated control will begin the ignition sequence again.

Fan Time Control

Heating Fan On Time

The fan on time of 30 seconds is not adjustable.

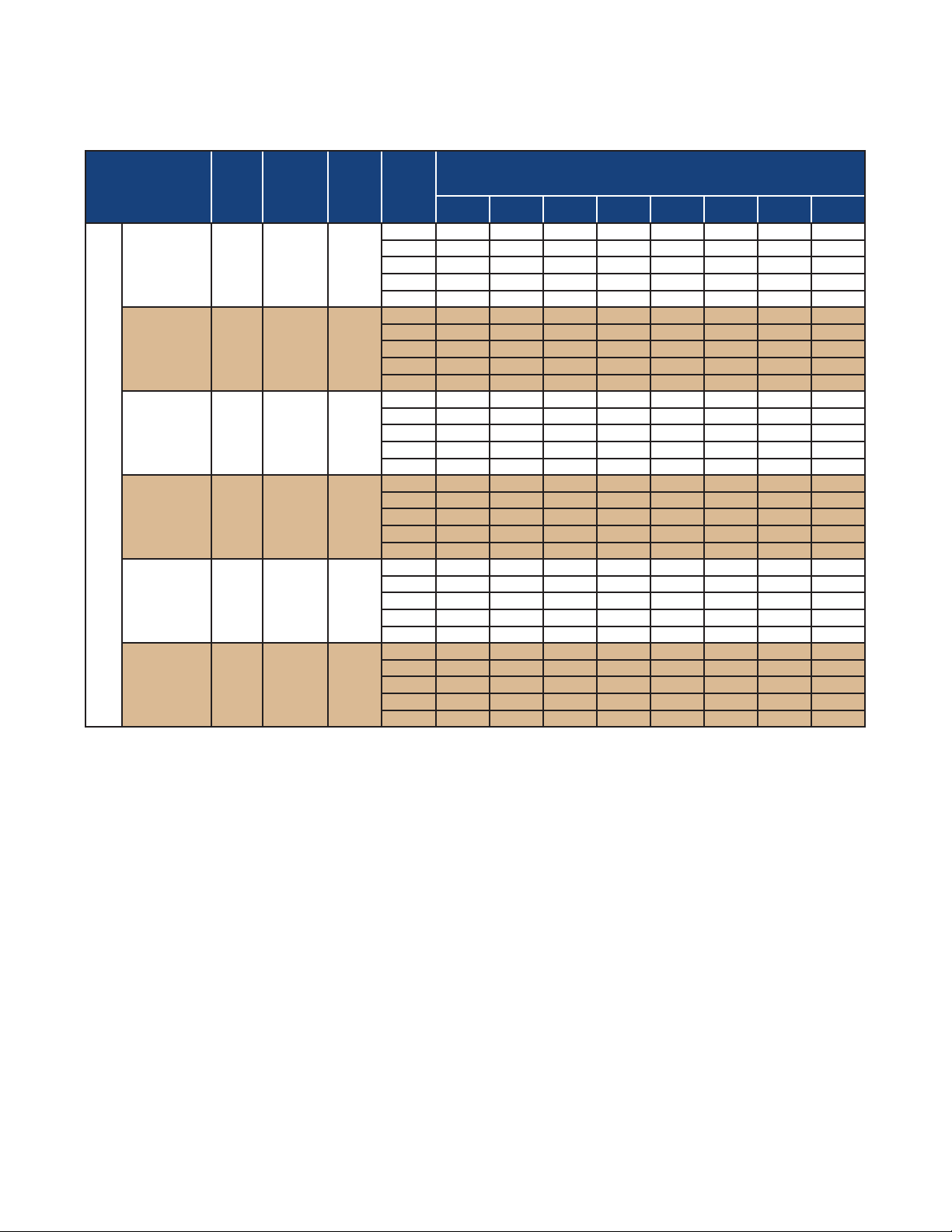

Heating Fan O Time

Fan o time (time that the blower operates after the heat

demand has been satised) can be adjusted by moving

the jumper to a dierent setting. The unit is shipped with

a factory fan o setting of 90 seconds. For customized

comfort, monitor the supply air temperature once the heat

demand is satised. Note the supply air temperature at the

instant the blower is de-energized.

Adjust the fan-o delay to achieve a supply air temperature

between 90° - 110° at the instant the blower is de-energized.

(Longer delay times allow for lower air temperature, shorter

delay times allow for higher air temperature). See Figure 4.

Cooling Fan On Time

The fan on time is 2 seconds and is not adjustable.

Cooling Fan O Time

The control has a 45 second fan o delay after cooling

demand has been met. This delay is factory set and not

adjustable.

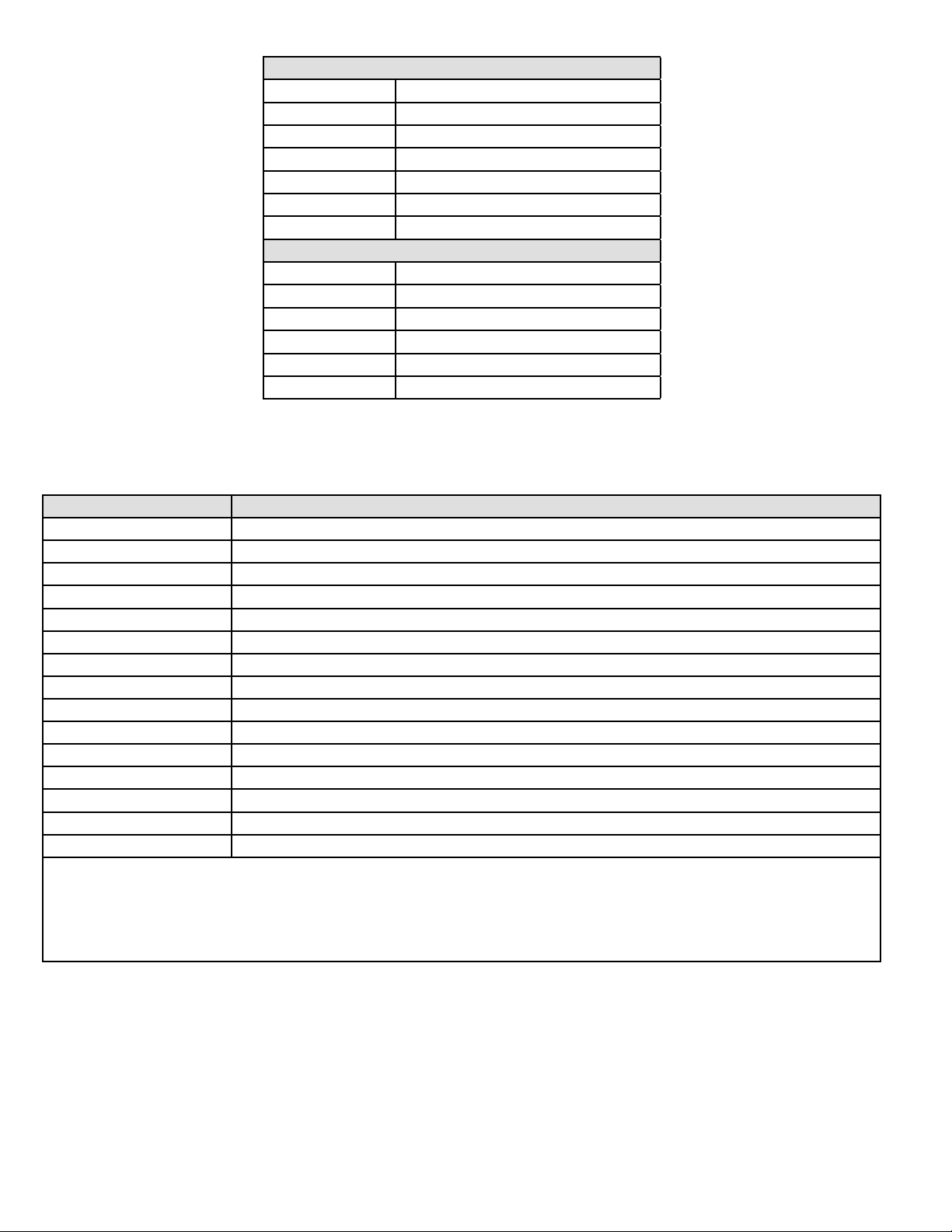

Figure 4.

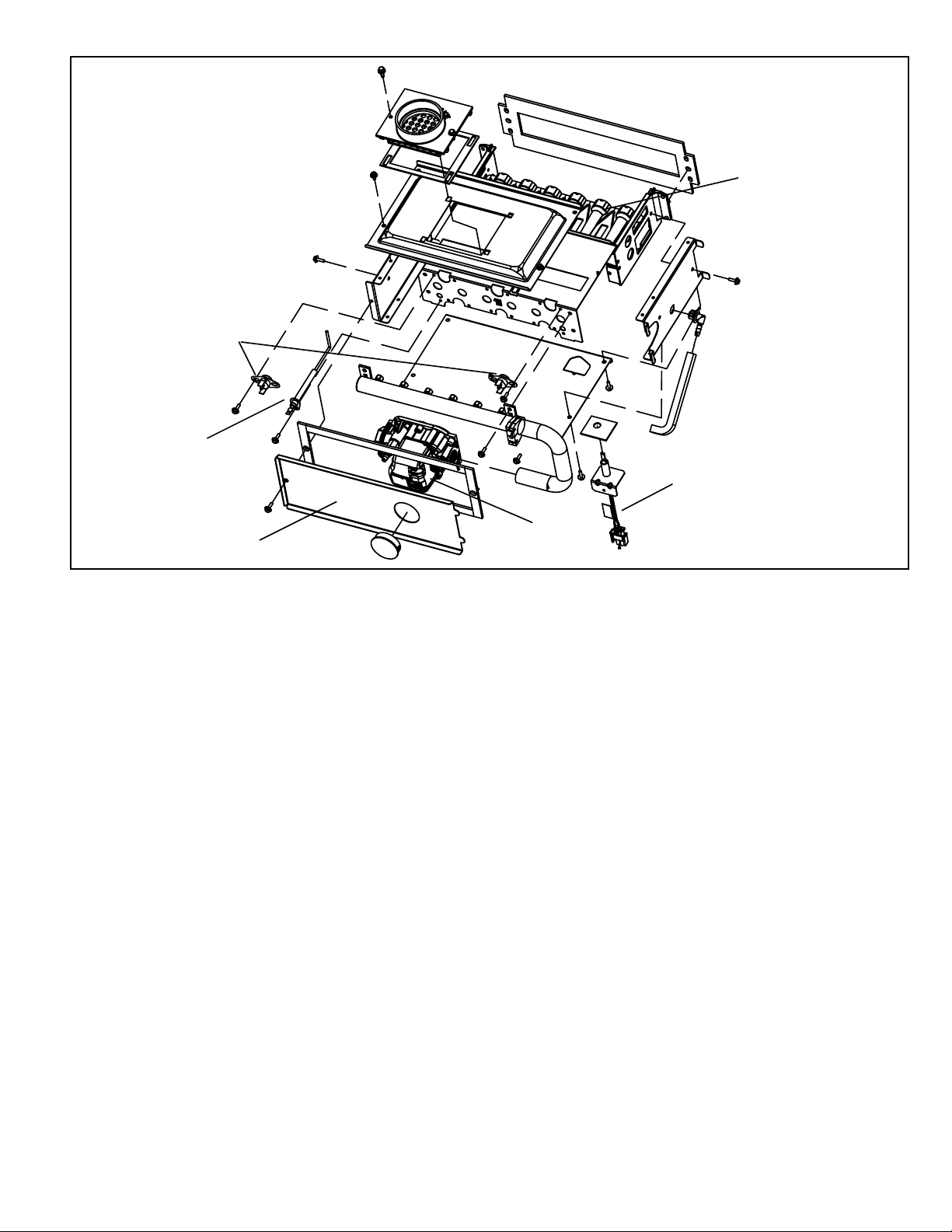

Heating Components

Combustion air inducer (B6), primary limit control (S10),

ignitor, burners, ame rollout switch (S47), gas valve

(GV1), combustion air pressure switch (S18), and heat

exchangers are located in the heating compartment. The

heating compartment can be accessed by removing the

outer access panel.

GUH92C units use a nitride ignitor made from a

proprietary ceramic material. To check ignitor, measure

its resistance and voltage. A value of 39 to 70 ohms

indicates a good ignitor. Voltage to the ignitor should be

102 - 132VAC. See Figure 9 for resistance and voltage

checks.