3

CONTENTS

CONTENTS........................................................................................................................................ 3

Reference list .................................................................................................................................... 5

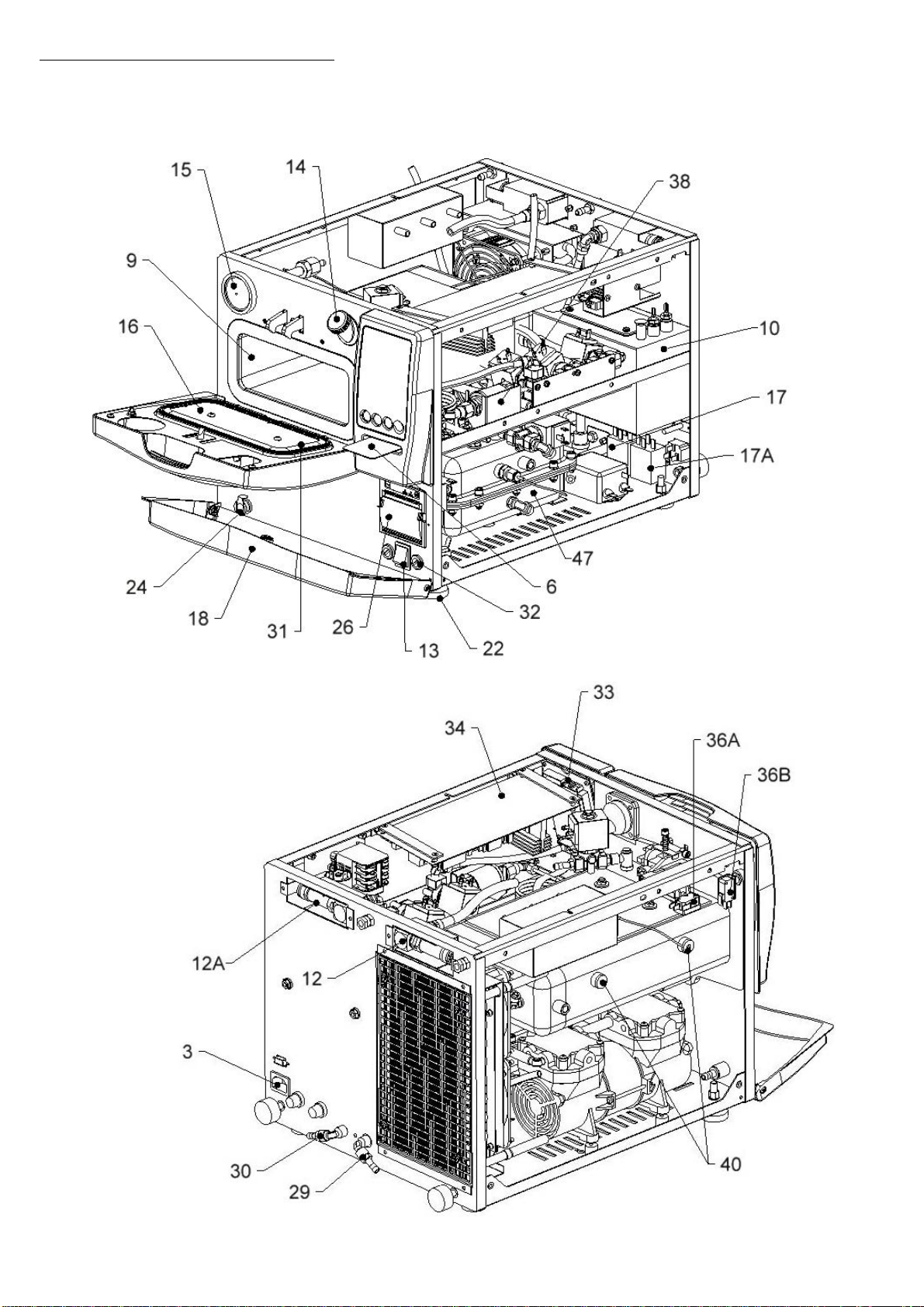

Graphical reference representation Mod. 6 B SPEEDY............................................................. 6

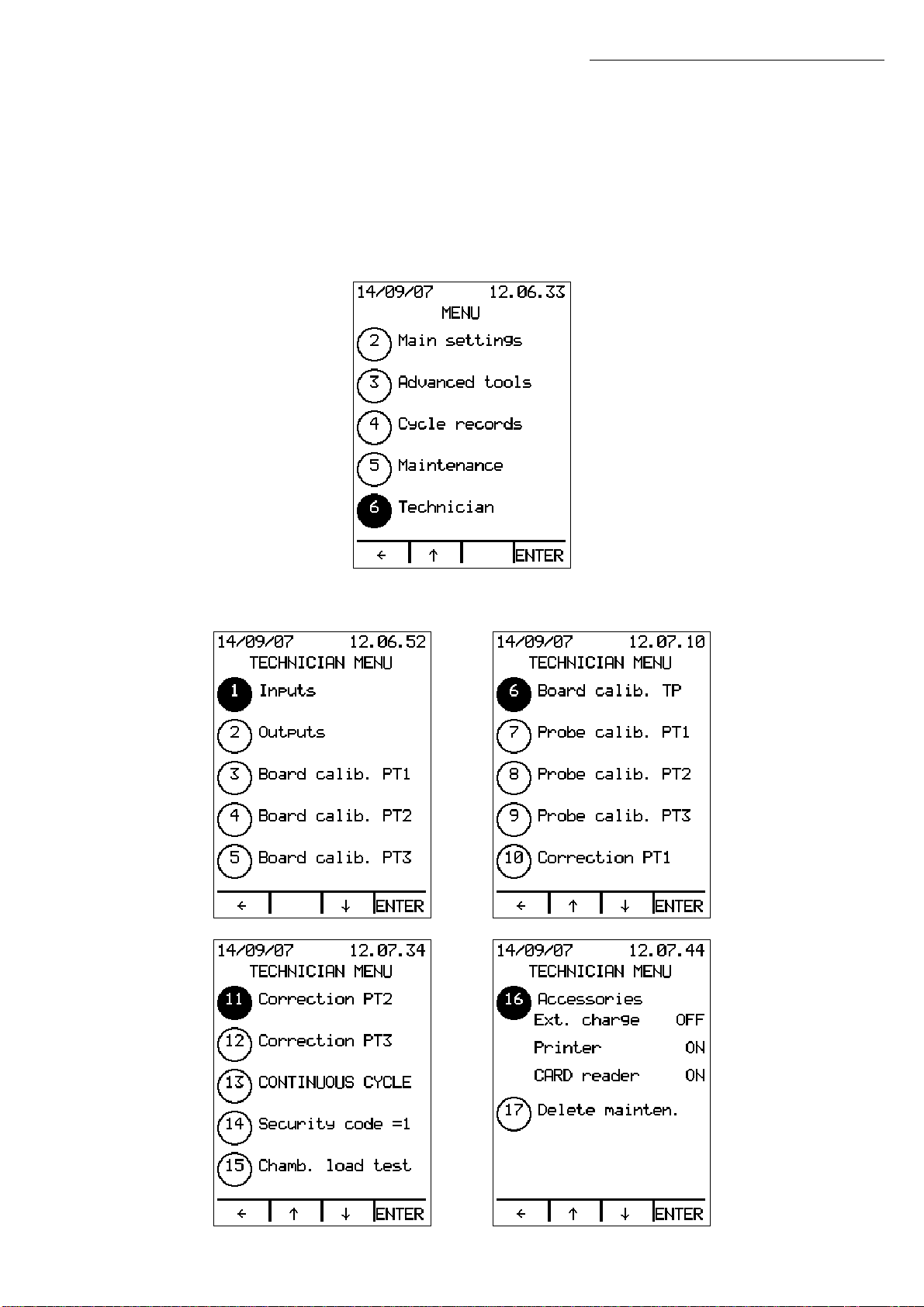

TECHNICIAN MENU ......................................................................................................................... 9

Inputs ............................................................................................................................................... 10

Outputs............................................................................................................................................ 11

PT1 / PT2 / PT3 board calibration ................................................................................................ 12

Temperature selector ................................................................................................................... 12

TP board calibration...................................................................................................................... 16

PT1 / PT2 / PT3 probe calibration ................................................................................................ 18

PT1 / PT2 / PT3 correction ............................................................................................................. 18

Continuous cycle........................................................................................................................... 19

Security code ................................................................................................................................. 19

Accessories ..................................................................................................................................... 20

Delete maintenance .................................................................................................................... 20

Simplified version of the Technician Menu (PUCK)................................................................... 21

Main Settings Menu...................................................................................................................... 21

MAINTENANCE .............................................................................................................................. 22

Items................................................................................................................................................. 22

Save maintenance ....................................................................................................................... 23

Scheduled maintenance table................................................................................................... 24

MESSAGES...................................................................................................................................... 25

Scheduled maintenance............................................................................................................. 25

Check water quality ..................................................................................................................... 25

Cooling pause................................................................................................................................ 25

Generator warm up ...................................................................................................................... 26

ALARMS.......................................................................................................................................... 27

Insufficient water quality alarm................................................................................................... 27

Insufficient water level alarm....................................................................................................... 27

Insufficient steam alarm ............................................................................................................... 28

Pressurisation alarm ....................................................................................................................... 29

PT1 overtemperature alarm......................................................................................................... 29

Insufficient vacuum alarm ........................................................................................................... 29

Fractioned vacuum alarm........................................................................................................... 30

Sterilization temperature band alarm: overtemperature / undertemperature ................. 30

Level probe alarm ......................................................................................................................... 31

Coil alarm........................................................................................................................................ 32

Self-filling alarm .............................................................................................................................. 32

Door alarm...................................................................................................................................... 32

PT1 temperature probe alarm..................................................................................................... 34

Drain alarm ..................................................................................................................................... 34

Misalignment alarm....................................................................................................................... 34

Pressure transducer alarm............................................................................................................ 34

Manual stop alarm ........................................................................................................................ 35

ContentsContents