Command Light

2

USER-GUIDE_Traffic_Flow_Board.doc

Please take the time to read this manual before installing or operating the Traffic Flow Board.

Save this guide for future reference.

CONTENTS

COMMAND LIGHT........................................................................................................................................................................ 1

1. BREAKAGE OR DAMAGE DURING SHIPMENT................................................................................................................ 3

2. GENERAL DESCRIPTION AND SPECIFICATIONS............................................................................................................ 4

3. PRODUCT SAFETY PRECAUTIONS...................................................................................................................................... 4

4. OPERATION................................................................................................................................................................................ 5

RAISING THE LIFT FROM THE NESTED POSITION .............................................................................................................................. 5

RETURNING THE LIFT TO THE NESTED POSITION .............................................................................................................................. 5

AUTO-PARK SEQUENCE .................................................................................................................................................................. 5

5. INSTALLATION.......................................................................................................................................................................... 6

INSTALLATION KIT ......................................................................................................................................................................... 6

TOOLS REQUIRED ........................................................................................................................................................................... 6

LOCATION REQUIREMENTS ............................................................................................................................................................. 6

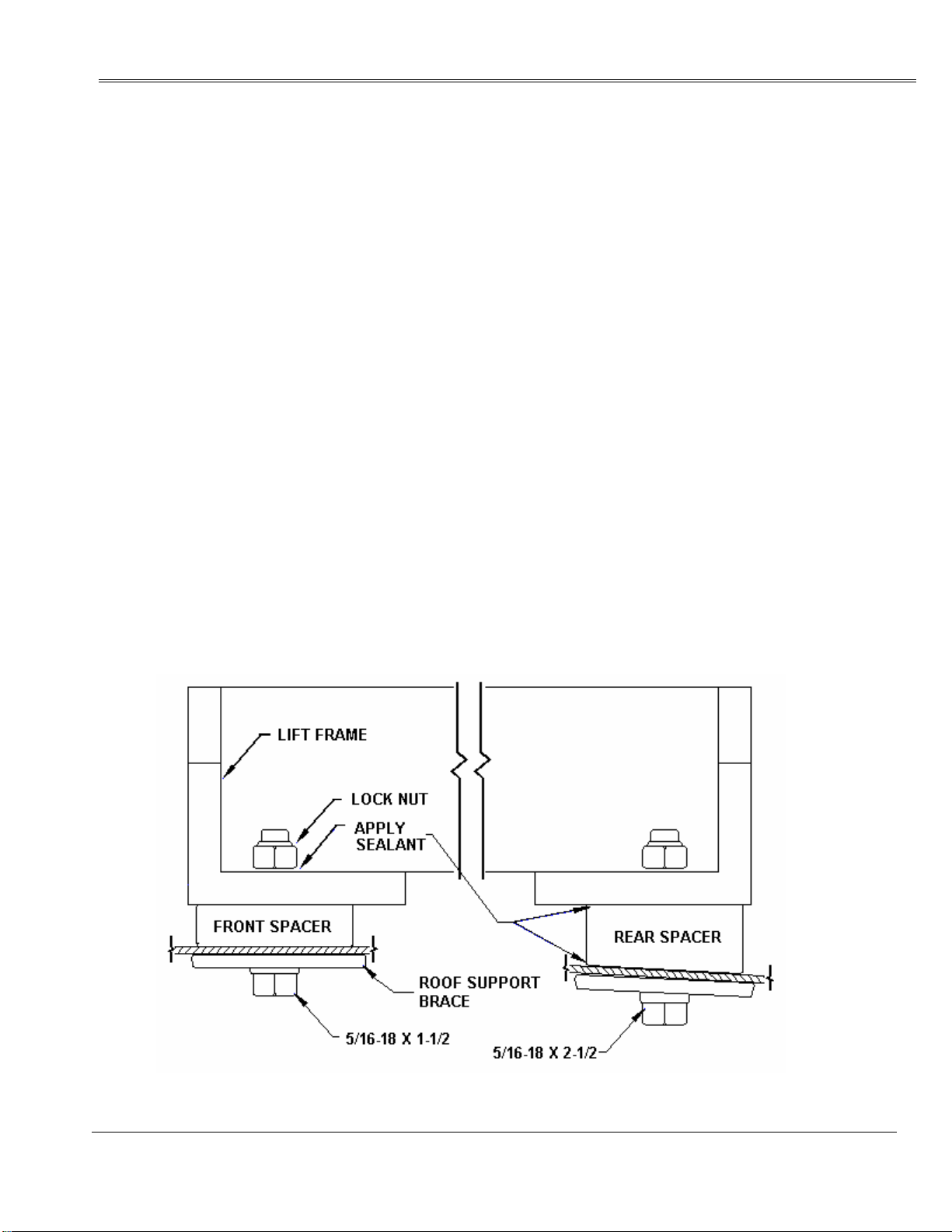

MOUNTING ..................................................................................................................................................................................... 7

CONTROL BOX POCKET MOUNTING ............................................................................................................................................... 8

6. ELECTRICAL WIRING............................................................................................................................................................. 8

7. MAINTENANCE.......................................................................................................................................................................... 8

8. POWER FAILURE...................................................................................................................................................................... 8

REMOVE THE ARROW BOARD ACTUATOR FIRST. ............................................................................................................................. 8

RETRACT THE LIFT ARM.................................................................................................................................................................. 9

9. PARTS BREAKDOWN............................................................................................................................................................. 10

10. TECHNICAL SPECIFICATIONS ......................................................................................................................................... 11

11. WIRING SCHEMATIC........................................................................................................................................................... 13

12. LIMITED WARRANTY.......................................................................................................................................................... 15

1/3/2006