Contents

To the owner / user ........................................................................................................................................................3

Warranty ......................................................................................................................................................................3

Safety ..............................................................................................................................................................................3

Safety symbols ...........................................................................................................................................................4

Safety and information labels that are required on the wheel dolly ....................................................................5

General safety.............................................................................................................................................................6

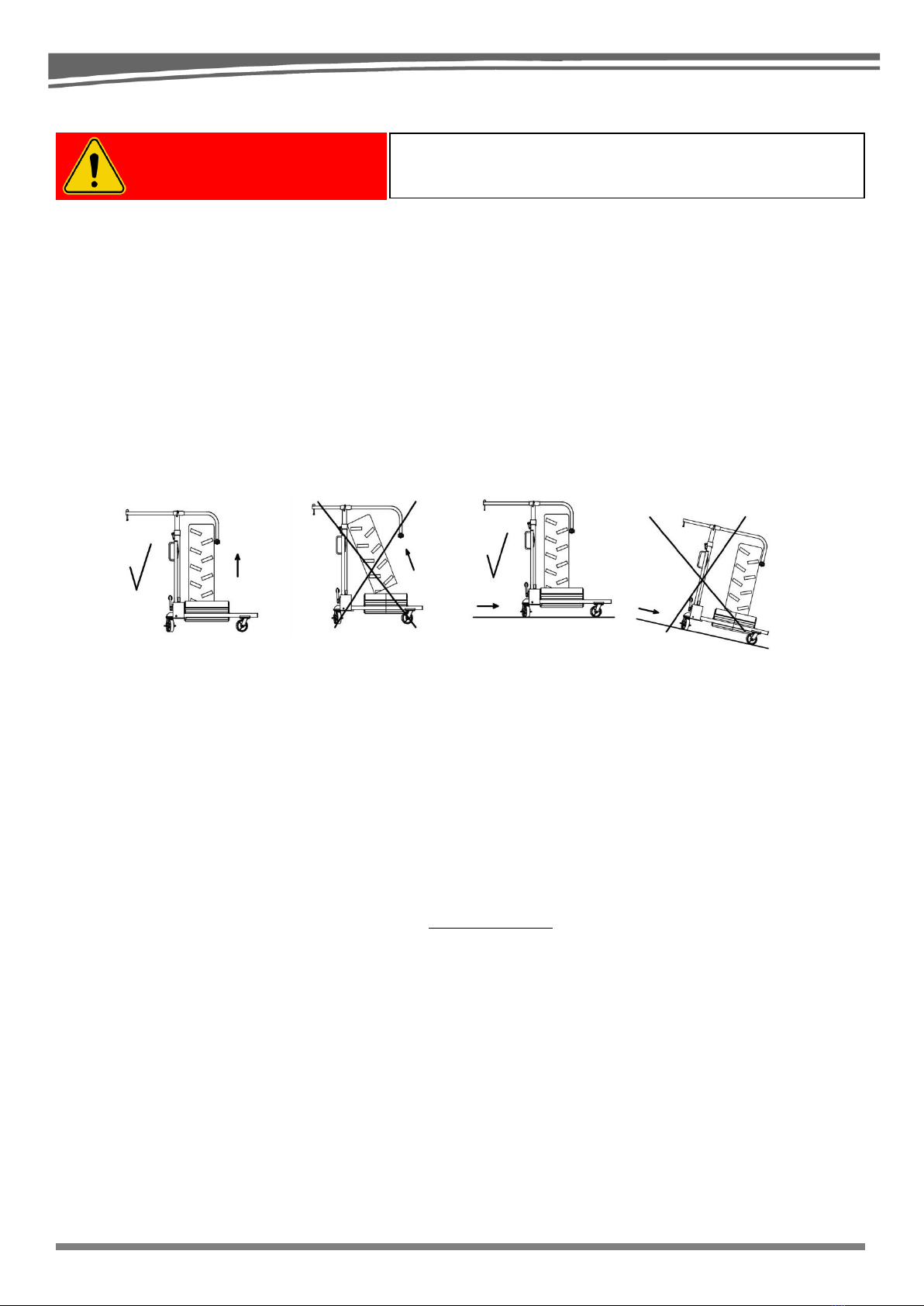

Transporting the WD 1600 Wheel Dolly......................................................................................................................7

Preparation and assembly prior to use ...................................................................................................................7

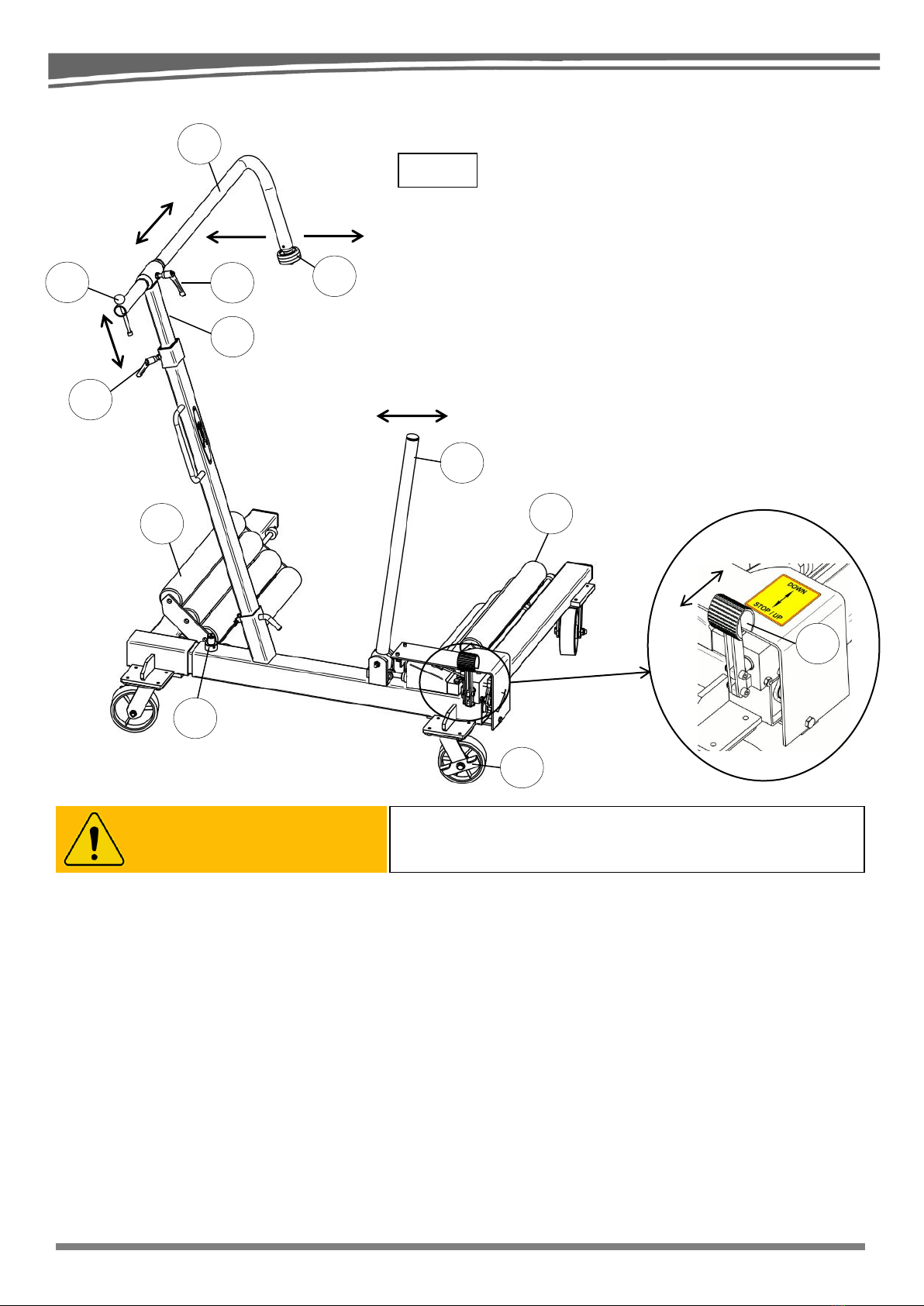

Component overview .....................................................................................................................................................8

Functional description................................................................................................................................................8

Operating instruction......................................................................................................................................................9

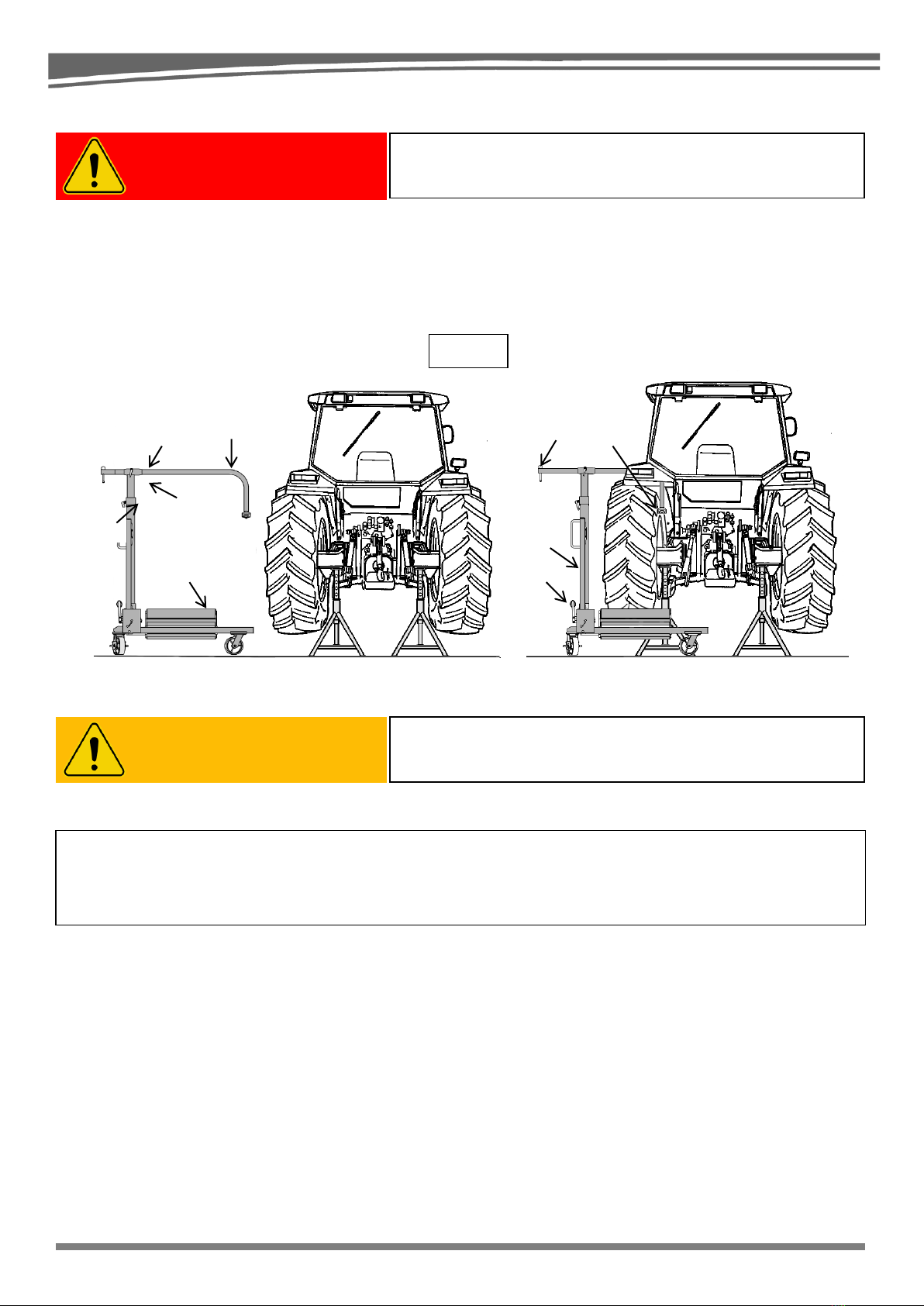

Safe operation –Lifting for wheel dismount ............................................................................................................9

Safe operation –Manoeuvring with wheel / load..................................................................................................10

Safe operation –Stopping lowering manoeuvres.................................................................................................11

Safe operation –Lowering for wheel mount..........................................................................................................11

Maintenance instructions ............................................................................................................................................12

General maintenance ..............................................................................................................................................12

Cleaning.....................................................................................................................................................................12

Storage.......................................................................................................................................................................12

Repair.........................................................................................................................................................................12

Oil change .................................................................................................................................................................12

Oil information...........................................................................................................................................................12

Annual maintenance ................................................................................................................................................12

Disposal / destruction ..............................................................................................................................................12

Specifications WD1600 ...............................................................................................................................................13

Periodic maintenance and inspection .......................................................................................................................14

Service Log ...............................................................................................................................................................17

Attached documentation:

CE Certificate

Spare parts list

Assembly Instructions for WD1600