Sicherheitsanweisungen –ABSENKEN / MONTAGE DES RADS

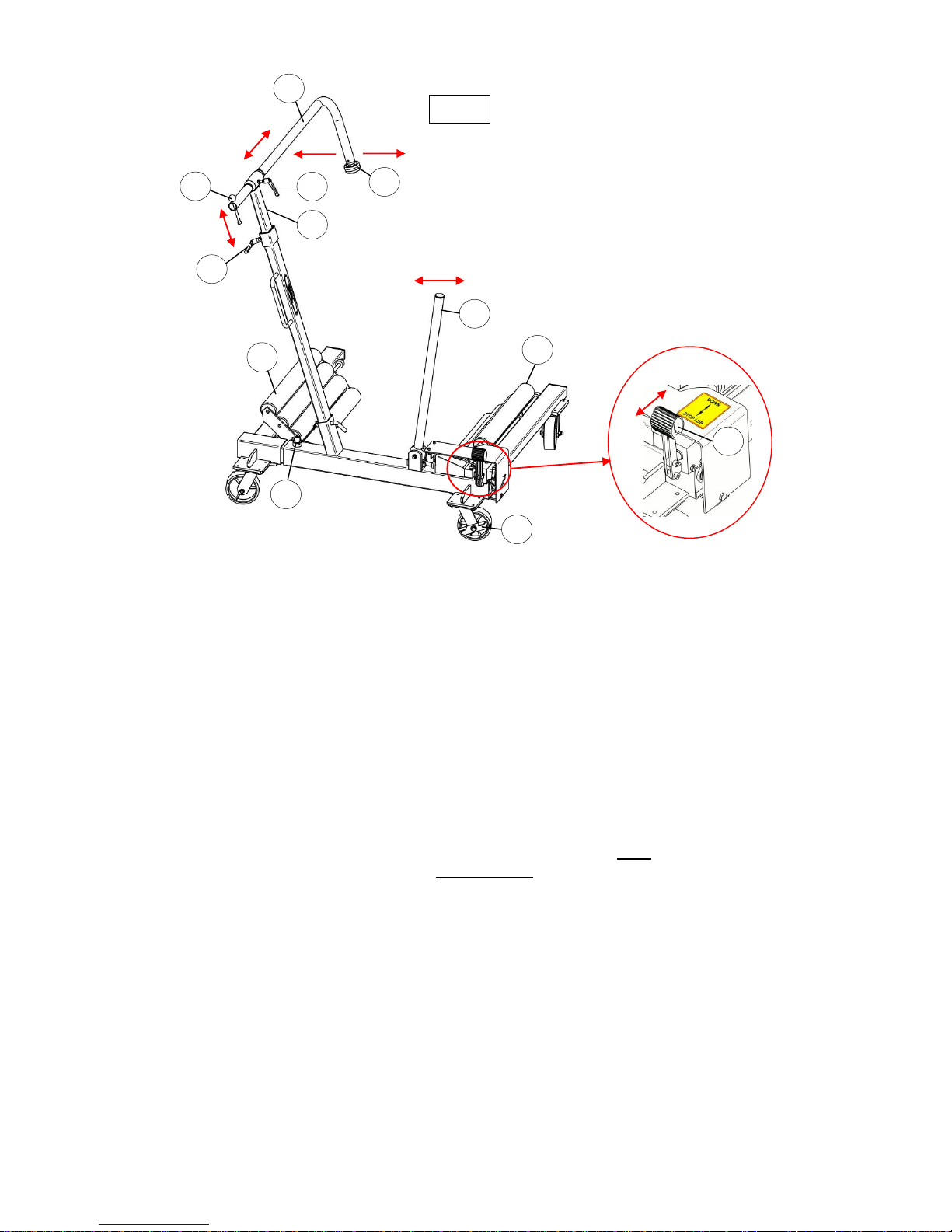

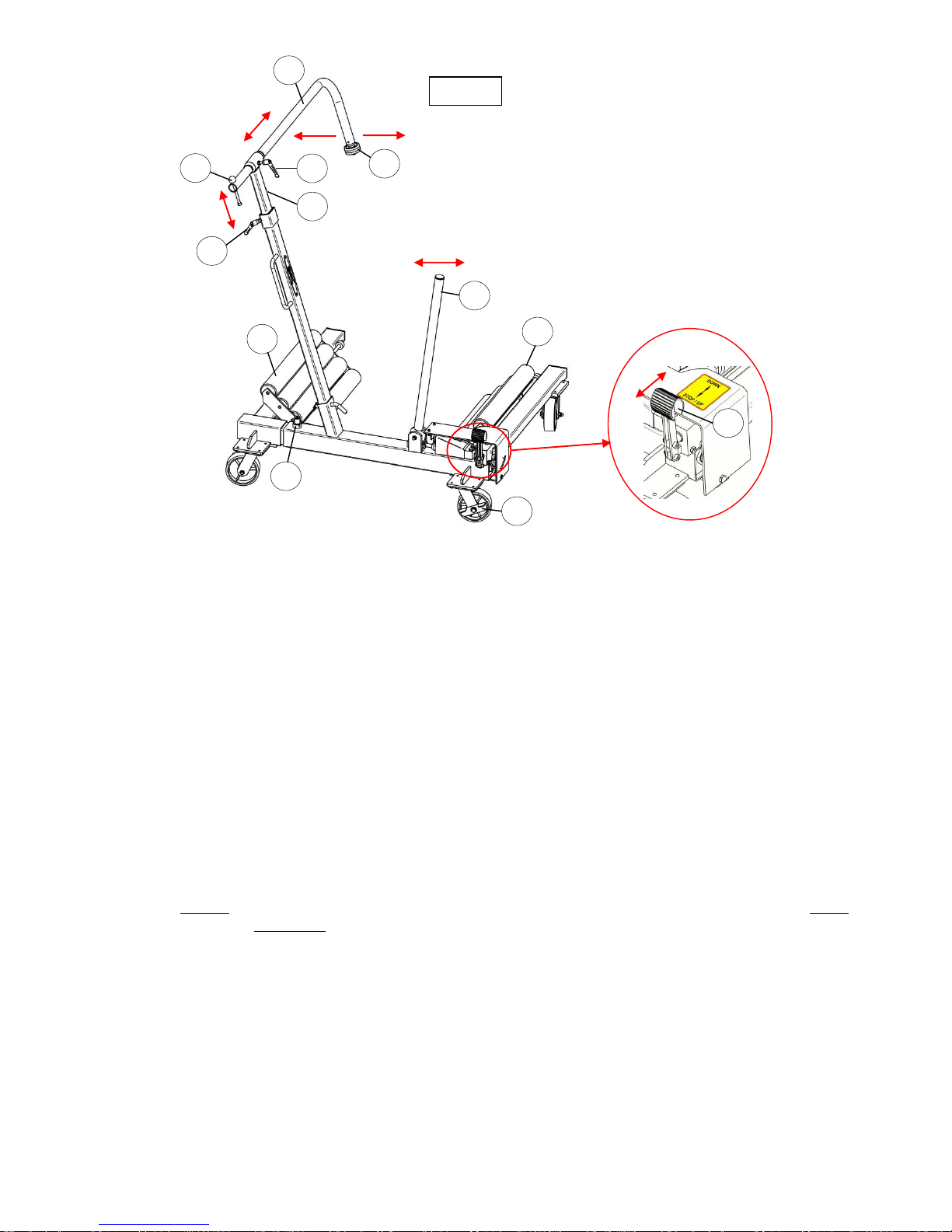

1. Lösen Sie den Sicherheitsstift (S).

2. Überprüfen Sie vor dem Absenken, dass das kleine Stützrad (W) fest am Rad/der Last sitzt.

3. Vor dem Absenken des Rads/der Last muss sichergestellt werden, dass der senkrechte Hebel

(L) gelöst ist und sich frei bewegen kann.

4. Sobald Sie langsam beginnen das Rad/die Last abzusenken, sollte der Führungshebel (L) der

Bewegung des Rads frei beweglich folgen können. Ist das nicht der Fall, besteht die Gefahr,

dass das Rad aus der Unterstützung (W) auf der anderen Seite läuft, und dadurch

versehentlich heraus fällt.

5. Aktivieren Sie den Pumpenhebel (P), um die Last abzusenken oder die korrekte

Montagehöhe zu erreichen.

6. Sobald die Einheit vom Rad/der Last entfernt werden kann, werden der Verschlussgriff (K)

und das Stützrad (W) vom Rad gelöst. Ziehen Sie die Einheit zurück.

Sicherheitsanweisungen –BEWEGEN MIT RAD / LAST

1. Sorgen Sie dafür, dass das kleine Stützrad (W) das Rad/die Last korrekt abstützt.

2. Sorgen Sie dafür, dass sich die Verschlüsse (M), (L) und (S) in verschlossener Position

befinden.

WARNUNG Sicherheitsanweisungen:

Sorgen Sie dafür, dass nur auf einer ebenen und stabilen Unterlage gehoben wird.

Das Rad/die Last muss senkrecht gehoben werden, da es anderenfalls an den Walzen von der

Einheit gleiten kann, wodurch sich die Einheit auf den Bediener zu bewegen kann.

Überlasten Sie die Einheit nicht! Ein Überlasten mit Lasten über 1500 kg kann zu Beschädigungen

der Einheit führen, schlimmstenfalls zu anderen Beschädigungen oder sogar Unfällen!

Das Absenken einer Last über 1500 kg auf die Einheit kann zu schweren Beschädigungen der

Einheit führen. Beispiel: Wenn der Bediener das Fahrzeug selbst absenkt, bevor der Radheber

abgesenkt und vom Fahrzeug entfernt wurde.

Vor dem Heben/Transport einer Last MUSS der Bediener Vorsorge treffen, dass die Last nicht

herabfallen kann und das Bewegen der Last sicher verläuft. Vor der Benutzung muss der Bediener

dafür sorgen, dass alle Stifte mit Splinten oder Verschlussringen sicher verschlossen sind.

(ACHTUNG! Die LAST muss blockiert sein, indem der Verschlussgriff (K) geschlossen und (W) sich

in korrekter Position befindet, um das Rad auf der entgegengesetzten Seite zu stützen.

Senken Sie die Last vor dem Transport immer bis auf die niedrigste Position ab.

Wichtig! Das Sicherheitsventil wurde vom Hersteller geeicht und versiegelt, wobei es ABSOLUT

VERBOTEN ist, das Siegel zu öffnen oder die Eichung zu justieren. Ein Verstoß gegen die oben

genannten Sicherheitsanweisungen kann schlimmstenfalls zum Kraftverlust führen, wodurch

Personen verletzt und/oder die Einheit oder Gegenstände beschädigt werden können. Sofern die

Einheit Unregelmäßigkeiten aufweist, die die Sicherheit beeinflussen können, darf sie bis zur

Reparatur nicht weiter bedient werden.

Die Einheit sollte nicht benutzt werden, sofern Öl leckt, oder sofern sie im Gebrauch anders wirkt als

im Neuzustand. In diesen Fällen sollte die Einheit von einem Fachmann untersucht/repariert werden.

Weitere Informationen zu Ersatzteilen usw. finden Sie auf www.compac.eu unter ”Service”.

Der Hersteller übernimmt keine Haftung für fehlerhafte Benutzung, Änderungen an der Konstruktion,

Verwendung nicht originaler Ersatzteile oder Justierungen/Reparaturen durch nicht autorisierte

Personen.

Sicherheitswartung:

Eine Durchsicht der Einheit darf aus Sicherheitsgründen nur ohne Last erfolgen. Die Einheit darf nur

durch Fachpersonal repariert/justiert werden. Verwenden Sie nur originale Ersatzteile. Bei

Justierungen befolgen Sie die Anweisungen des Herstellers. Weitere Informationen erhalten Sie

unter www.compac.eu