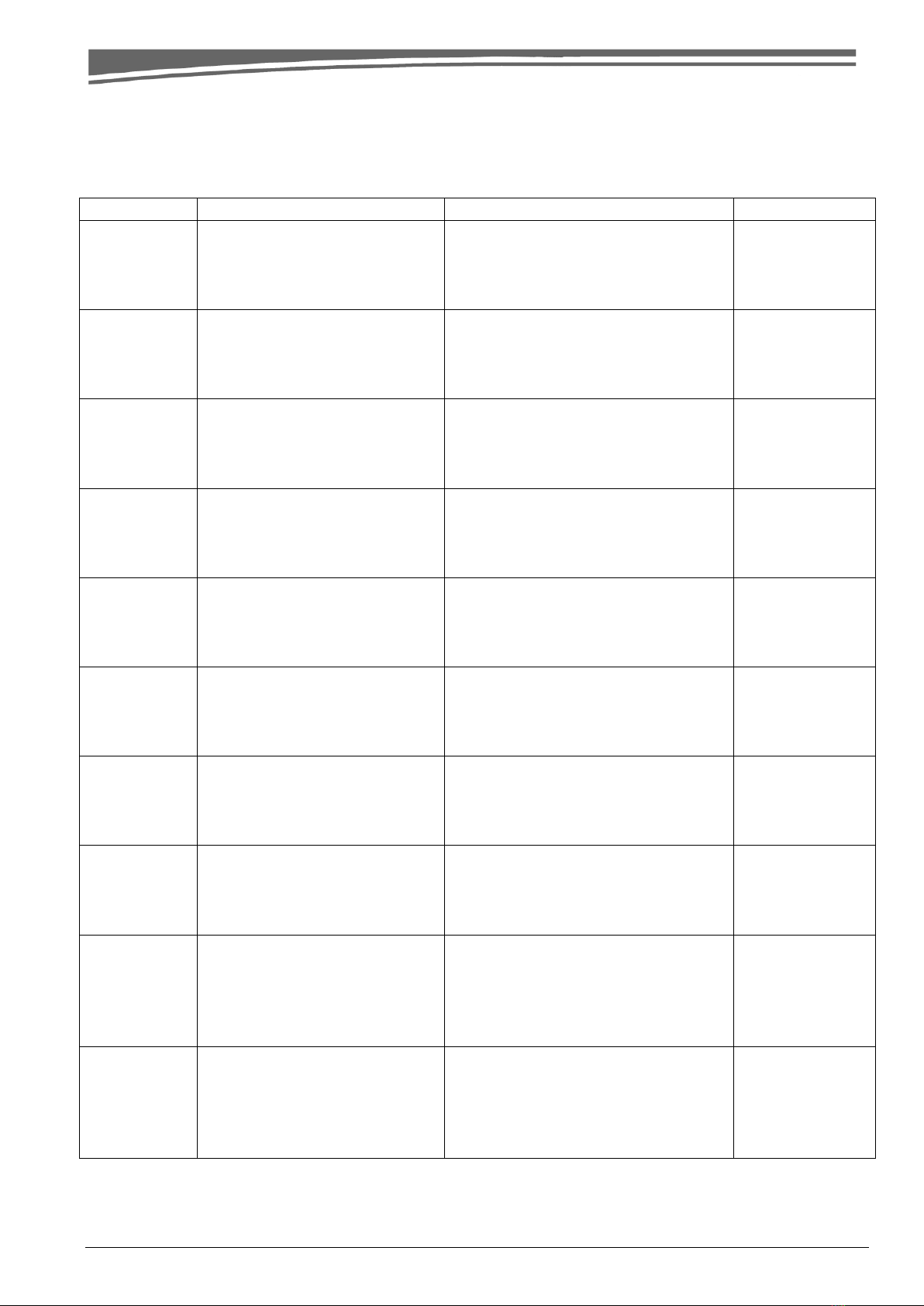

Maintenance

Annual inspection should be performed according to national regulations —and at least once a year.

The inspection should be performed by a trained professional.

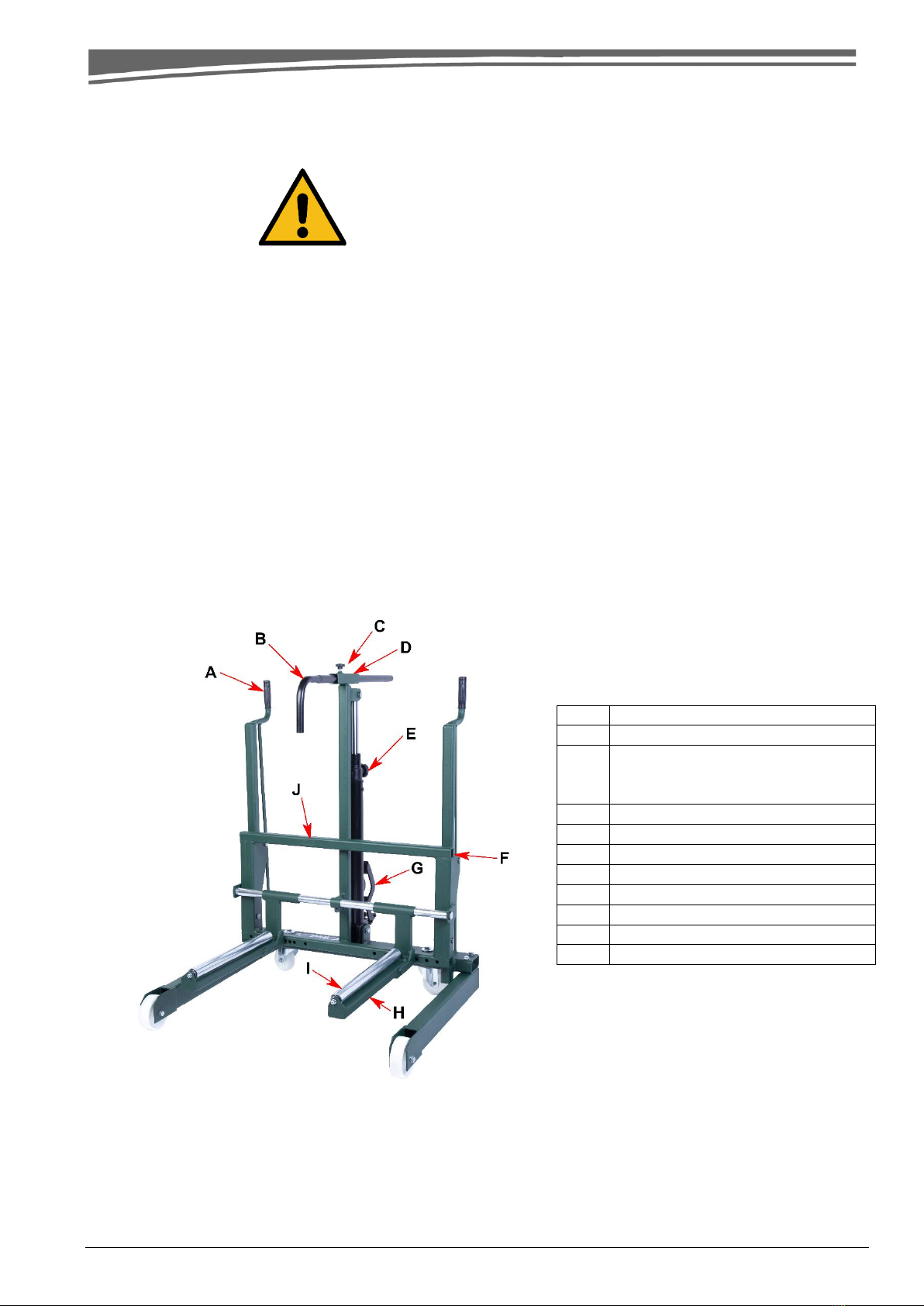

Chassis, tower, forks and other chassis parts must be checked for damage and abnormal wear.

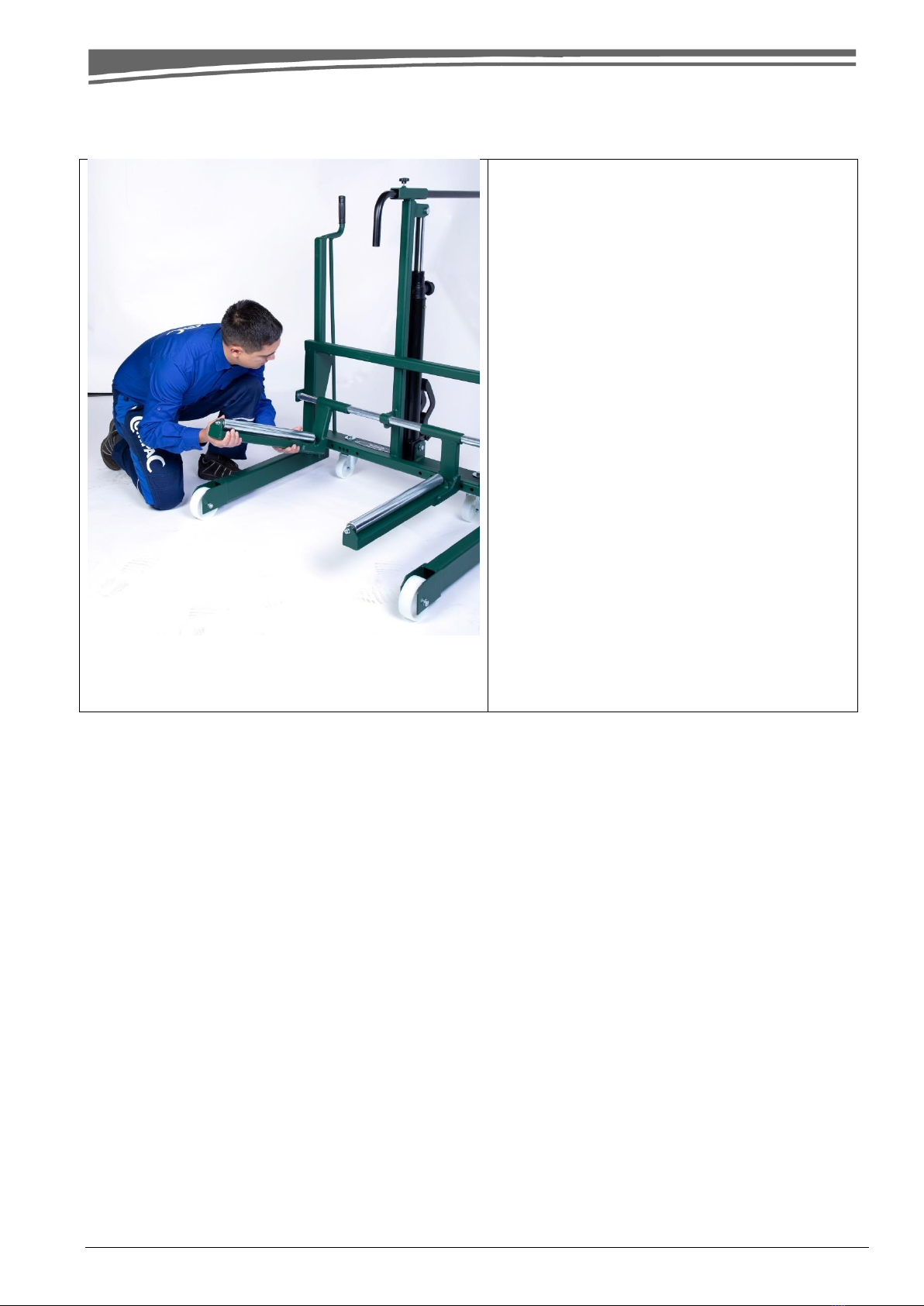

All moving parts must be inspected, cleaned and lubricated once a month.

In case of rust, remove the rust and protect with a rustproofing agent.

Check that the dowels on the forks and rollers are fully intact and working properly.

Check that retaining rings, nuts, bolts, and mandrels are fully intact and working properly.

If the unit requires repair, repair work must be done by a person with hydraulics experience/training.

If parts on the unit are replaced, they must be replaced with original parts.

If the unit has been defective or has malfunctioned, the unit must not be used until it has been

inspected by a person with hydraulics experience/training.

On the annual inspection, the machine must be serviced by a trained professional, so the above is

checked and any problems repaired.

Oil

Oil reservoir: Contains 0.95 litres.

Use only Hydraulic Oil AWS22

Do not use brake fluid, motor oil or the like!

Troubleshooting

1. The wheel lifter does not lift to the top position: The oil level is low. Lower the tower and fill to

the edge of the hole.

2. Poor pump function (“half” pump stroke): The oil level is too high. Lower the tower fully and let

the excess oil run out of the oil plug.

3. The tower sinks: Check that the release closes correctly.

If the error persists, repair the hydraulic unit.

Disposal

Drain the oil from the unit in a responsible manner and deliver the unit and other parts to an approved

waste recipient.