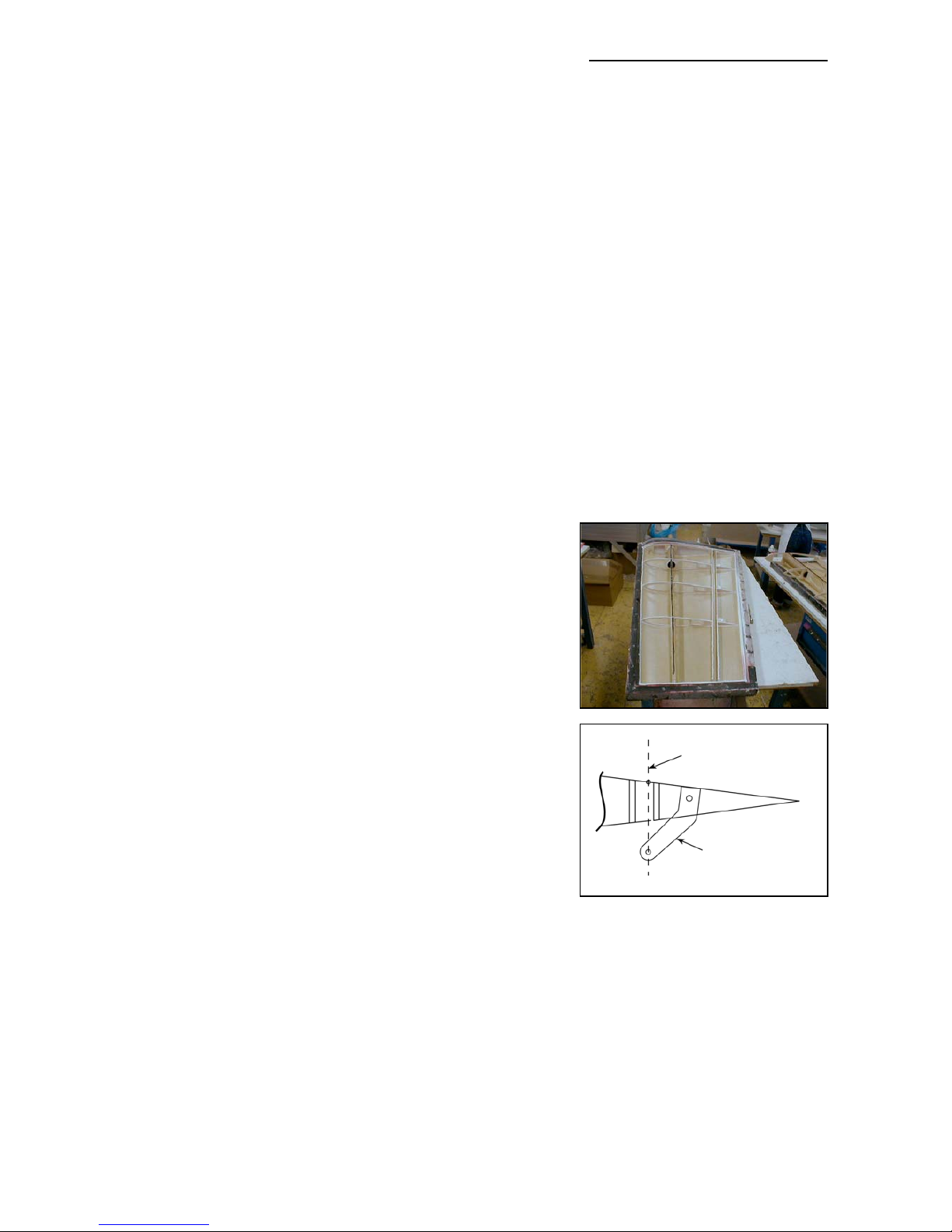

Make sure that the control horns are glued into the ailerons properly. The hole in the phenolic

horn for the quick-link needs to be exactly perpendicular to the hinge axis line, and in this

manual we show you a simple way to ensure that the horns in all pairs of control surfaces will be

identical, making it easy to set up your R/C for accurate flying manoeuvres.

For normal pattern flying one good servo for each aileron is enough, but if you want to do more

radical 3D manoeuvres, then fit 2 servos per aileron. We have supplied the extra 2 servo mounts

for you in the kit - all you need to do is cut out the servo cover hatches that are marked on the

bottom surface of the wing, and construct in the same way as the standard inner servo mounts.

The result is a rock solid servo mount and linkage, but still easy to maintain or exchange.

The wings are attached to the fuselage using the 4 threaded aluminium dowel anti-rotation pins,

with 4 plastic nuts inside the fuselage. If the aluminium dowels come loose in the wing, the wing

will slide outwards, away from the fuselage, and the main spar will definitely break. So take great

care to inspect the glue joints of these anti-rotation dowels in the wing REGULARLY. Excessive

vibrations or hard shocks can cause the glue joints to weaken or break. Monitor these joints

whenever you set up your plane. Never forget to tighten the nuts inside the fuselage. Your flight

will end after 100 ft and you will have to fix a hole in your club’s runway. Please DO NOT

modify these attachment dowels in any way, their perfect function is proven for many years.

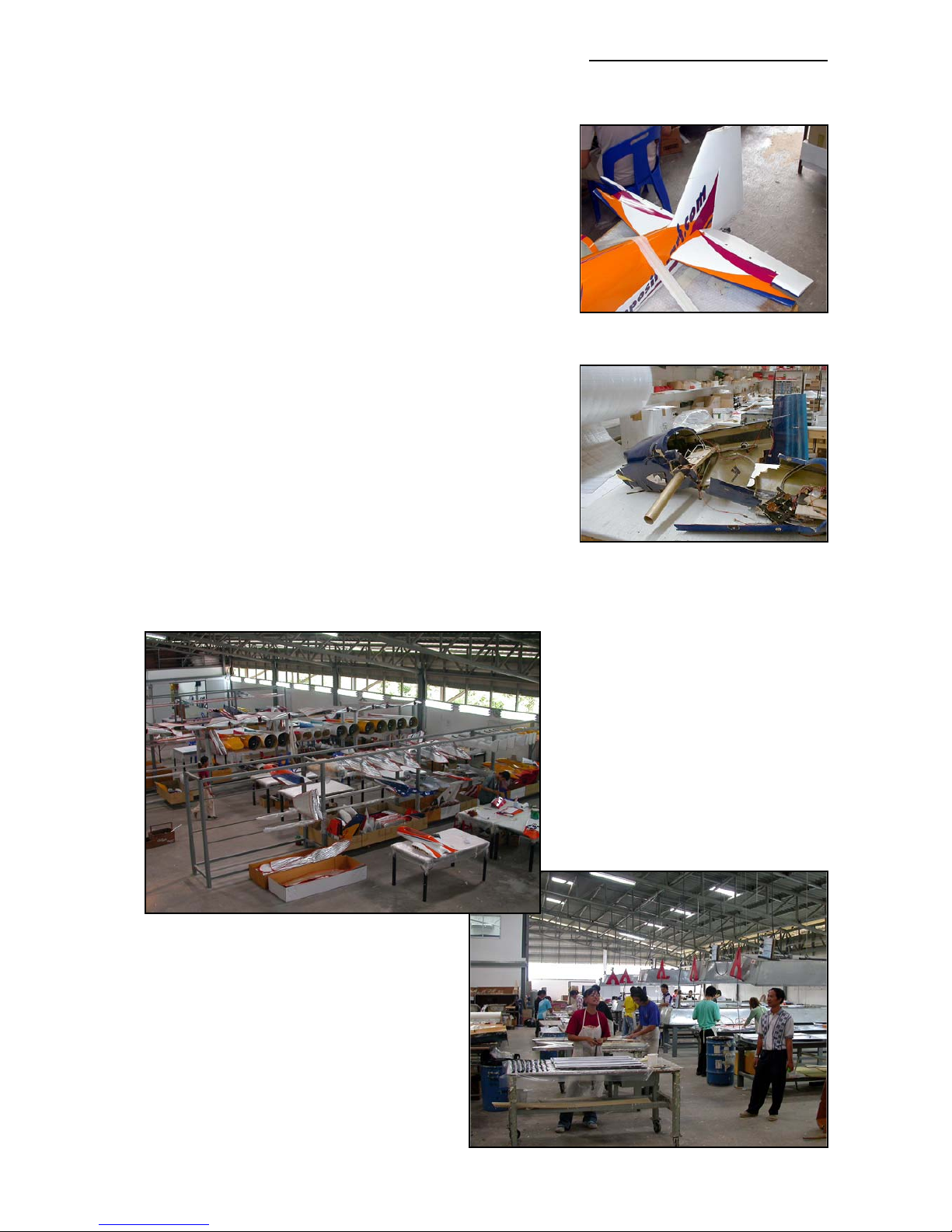

The Fuselage:

The fuselage is also made in negative moulds, and (except for the bottom surface) it is also all

constructed using TAVS technology. All the loadbearing internal parts are glued in during manu-

facture, to ensure accurate location and reduce the assembly time for you. The sleeves for wing

and stab spar tubes, and the holes and reinforcement plates for the anti-rotation dowels, are

already installed. There is no need to even check the incidences - you can be assured that these

are already set in the moulds so that no adjustment is necessary.

The landing gear mount is strong and doesn’t need any extra reinforcement. You have an

extremely light weight fuselage, and the gear loads need to be led into the structure gently. No

glue joint needs to be stronger than the materials that it is attached to, as it would just result in

increased weight for no advantage. The landing gear is a fairly flexible design, which works very

much like shock absorbers. This plane is not made for crashing, but the landing gear will take

some hard landings without problems. Do not change or modify it, as the results would only be

negative. We had plenty of time and experience to engineer the strength needed in this area -

and we did !

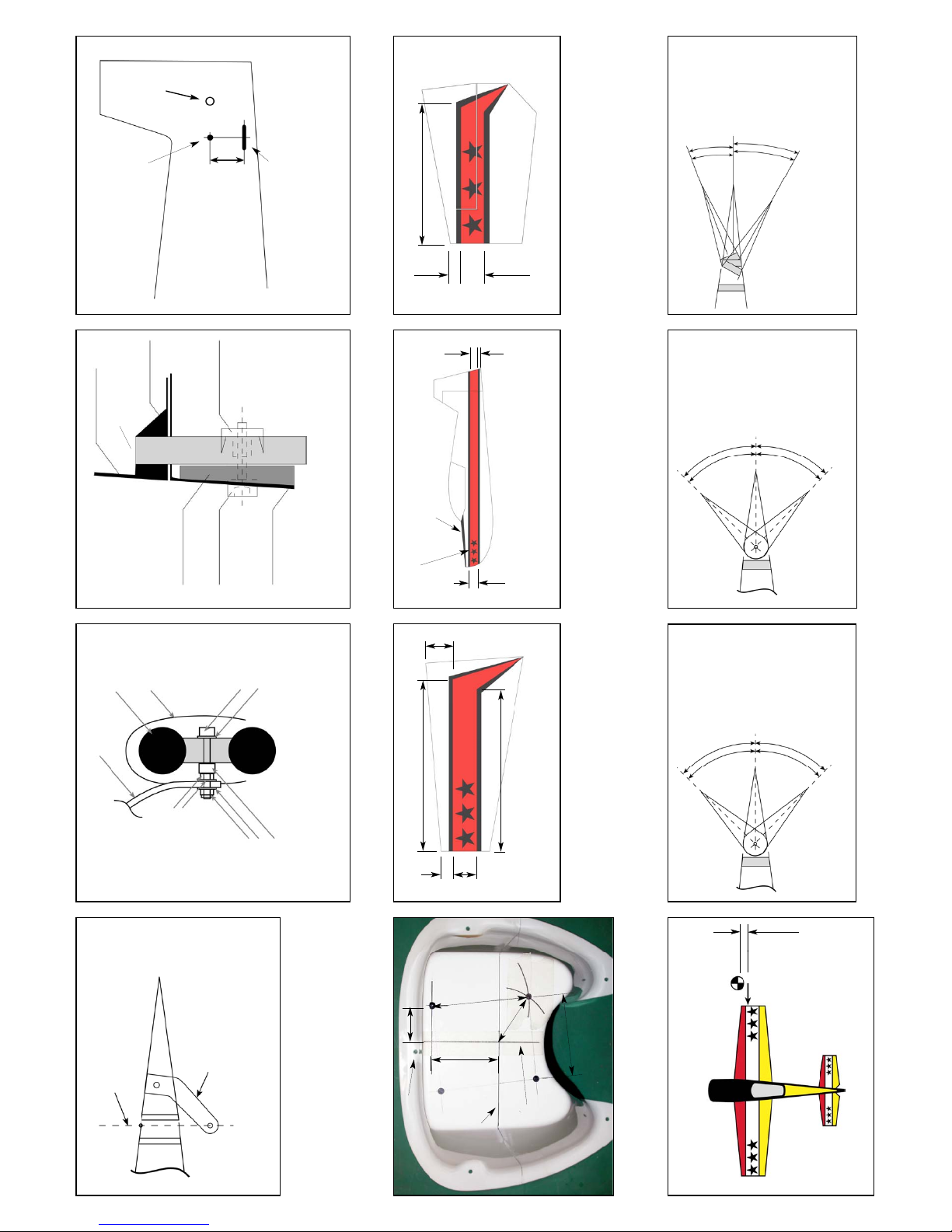

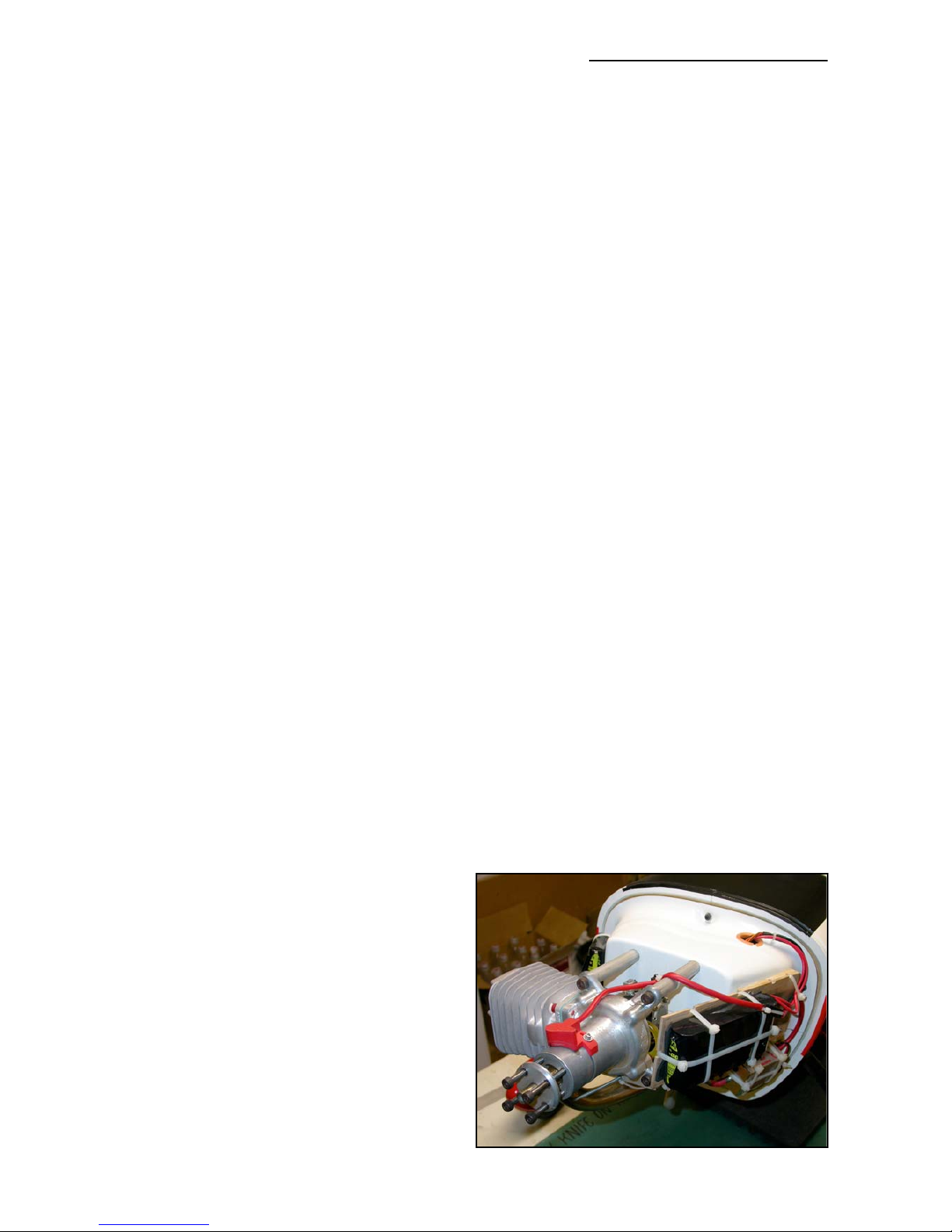

The firewall is preinstalled, and provides

plenty of strength for up to any 75 cc

engines on the market today. The mounting

holes in the firewall are are pre-drilled dur-

ing manufacture, and the corresponding

holes that you need to drill in the moulded

motor dome are marked for you in the

mould for the greatest accuracy. See the

Engine Installation section for adjusting the

mount and setting thrust angles.

The engine cowling and canopy frame

should be attached using the method

shown here. This is only a little work and all

suggested mounts are tested and proven

for many years.

6