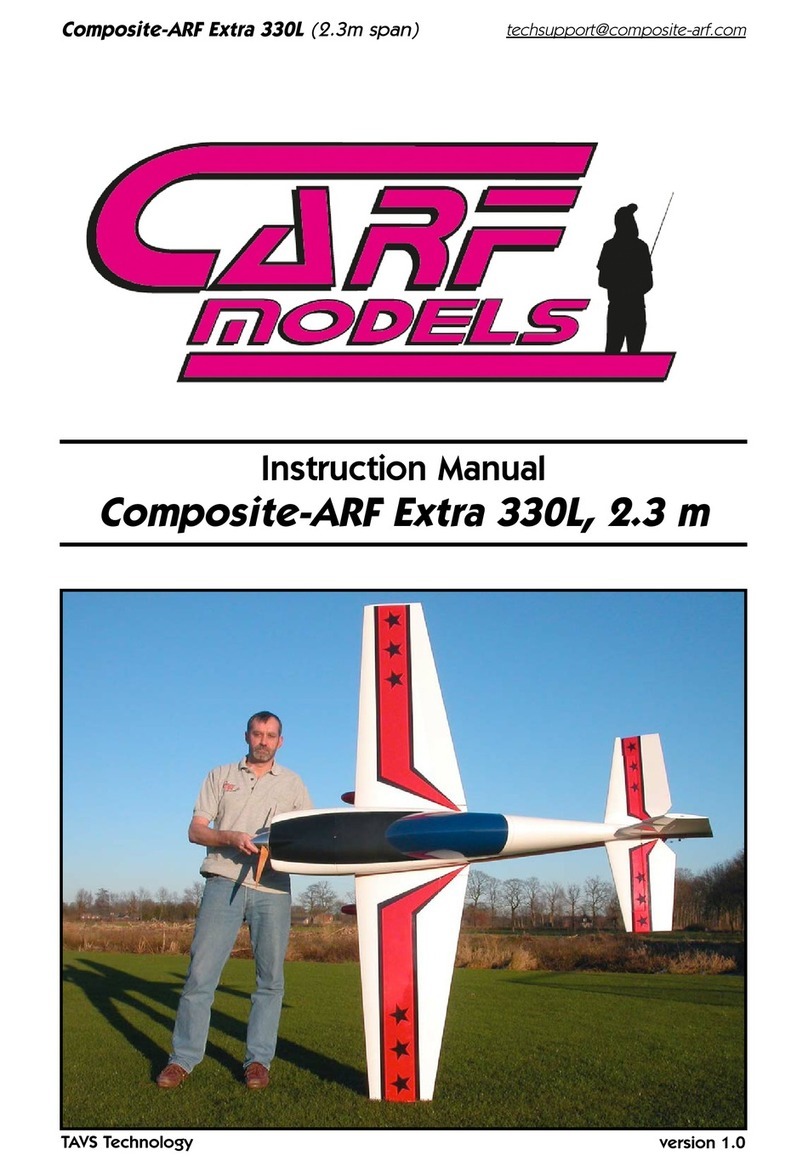

General information about

fully-composite aircraft structure and design

All the parts are produced in negative molds, manufactured using vacuum-bagged sandwich

construction technology. All parts are painted in the moulds, either single colour or designer

colour schemes. A new production method, called TAVS (Total Area Vacuum Sandwich), enables

us to present this aircraft with incredible built-in strength, while still being lightweight, and for a

price that nobody could even consider some years ago. This production process has huge

advantages, but a few disadvantages as well. These facts need to be explained in advance for

your better understanding.

Description of Parts

The Wings:

Both wing halves are made in negative moulds, and fully

vacuum bagged, using only 2 layers of 2 oz. cloth in com-

bination with a very hard 2 mm foam sandwich form a hard

and durable outer skin. Because of this TAVS technology

no additional structural parts are needed except for main

spars, which are the fully-floating, full depth, carbon rein-

forced blade type.

The ailerons are hinged already for you. They are laminat-

ed in the wing mould and are attached to the main wing

with a special nylon hinge-cloth, sandwiched between the

outer skin and the foam. This nylon hinge is 100% safe and

durable. You will never have to worry about breaking it, or

wearing it out. There is no gap at all on the top wing sur-

face, and there is a very narrow slot in the bottom surface,

where the aileron slides under the main wing skin during

down throw. This hinge setup is the cleanest you can ever

obtain, but you have to take some care during assembly for

proper installation and servo set up.

First, the hinge line is on the top surface of the wing, not in the centre. This is NOT a disadvan-

tage, if you set in about 10% NEGATIVE aileron differential in your transmitter program. This

means that the ‘down’ throw needs to be about 10% more than the up throw.

Why? Because the axis of the hinge is not at the centreline of the aileron, so it moves slightly

in and out when it travels, and the aileron gets a little "bigger" in surface area when moving up,

and "smaller" when moving down. This is why you have to set the negative differential in your

transmitter to compensate for the size changing. 10% is a good starting point, and you will find

out the exact setting during the first flights, doing fast vertical rolls and watching the fuselage

rolling in a perfect line. You can set it perfectly, this is guaranteed.

The bottom slot needs some explanation, too. The cut line is exactly in the correct position so

that the aileron slides under the wing skin smoothly. If the cut was a few mm forward or back, it

would not work properly. So, make sure that the lip is not damaged, and that the aileron slides

under this lip perfectly. It will NOT lock at any time, as long as the lip is not damaged. If damage

occurs to the lip, you can cut off 2-3 mm, but you should NEVER need to cut off more than this.

5

Centreline of hinge axis

Phenolic control horn