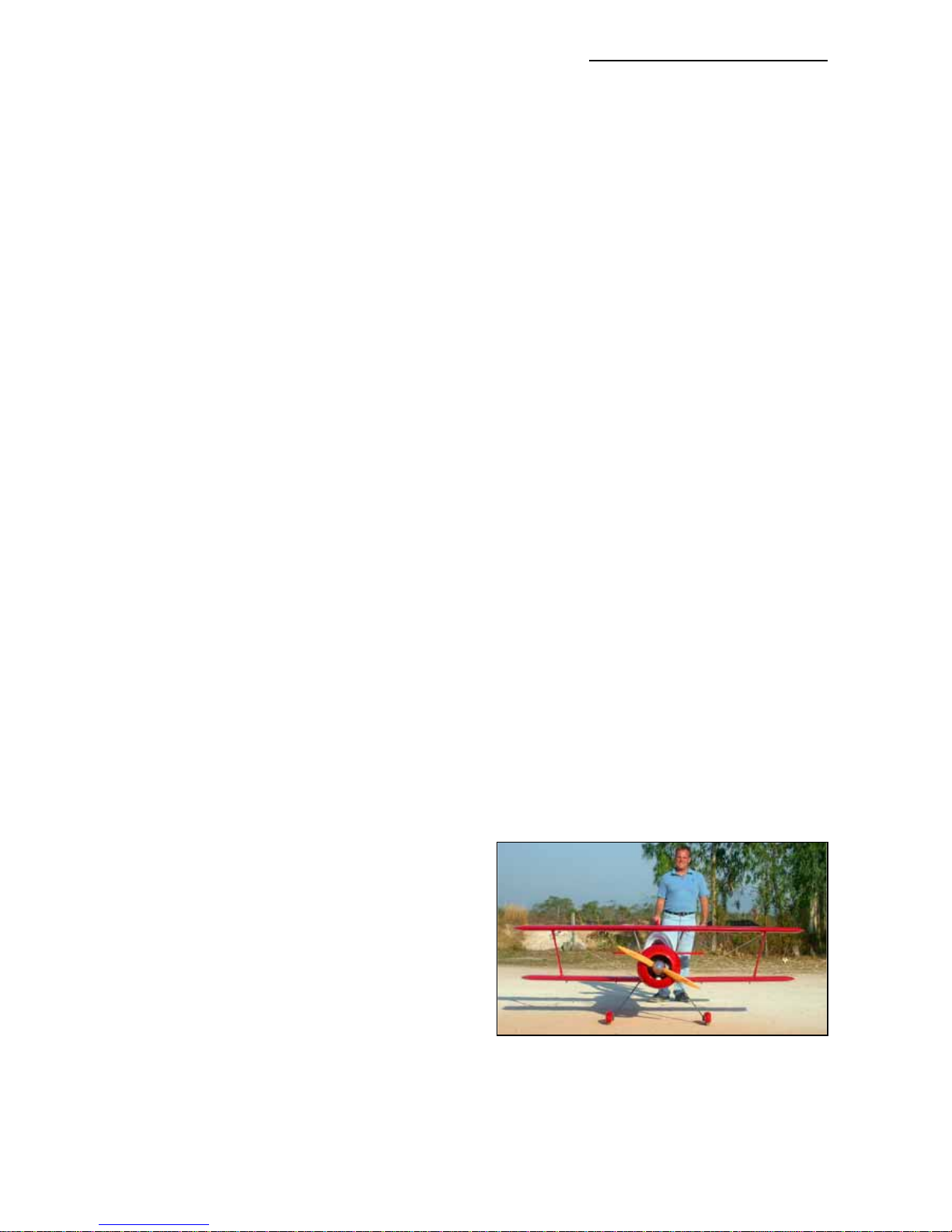

Instructions for Pitts S12 bi-plane

Thank you very much for purchasing our Composite-ARF Pitts S12 all composite aircraft, made

with the revolutionary Total Area Vacuum Sandwich (TAVS) technology.

This kit is designed for ‘expert’ assembly and operation, and therefore we have assumed that the

builder and operator of this aircraft has the necessary experience to do this safely and properly.

The Pitts S12 kit is 90% pre-fabricated at our factory, with the majority of the assembly already

completed - only requiring engine/exhaust system, R/C components and ancillaries to be

installed by the owner. These brief instructions detail the main points of the assembly, and show

the solutions used by our factory staff for the linkages, R/C installation and motor etc., which are

meant as a guide to assist you. Of course, if you have your own favourite and proven compo-

nents, hardware, accessories and techniques then by all means please use them.

Before you get started building and setting-up your aircraft, please make sure you have read this

instruction manual, and understood it. If you have any questions, please don’t hesitate to con-

tact your Rep, or C-ARF directly. Below are the contact details:

Telephone: Phone your C-ARF Rep!!! He will be there for you.

Website: http://www.composite-arf.com

Liability Exclusion and Damages

You have acquired a kit, which can be assembled into a fully working R/C model when fitted out

with suitable accessories, as described in the instruction manual with the kit.

However, as manufacturers, we at Composite-ARF are not in a position to influence the way you

build and operate your model, and we have no control over the methods you use to install,

operate and maintain the radio control system components. For this reason we are obliged to

deny all liability for loss, damage or costs which are incurred due to the incompetent or incorrect

application and operation of our products, or which are connected with such operation in any

way. Unless otherwise prescribed by binding law, the obligation of the Composite-ARF compa-

ny to pay compensation is excluded, regardless of the legal argument employed.

This applies to personal injury, death, damage to buildings, loss of turnover and business,

interruption of business or other direct and indirect consequent damages. In all circumstances

our total liability is limited to the amount which you actually paid for this model.

BY OPERATING THIS MODEL YOU ASSUME FULL RESPONSIBILITY FOR YOUR ACTIONS.

It is important to understand that Composite-ARF Co., Ltd, is unable to monitor whether you

follow the instructions contained in this instruction manual regarding the construction, operation

and maintenance of the aircraft, nor whether you install and use the radio control system

correctly. For this reason we at Composite-ARF are unable to guarantee, or provide, a

contractual agreement with any individual or company that the model you have made will

function correctly and safely. You, as operator of the model, must rely upon your own expertise

and judgement in acquiring and operating this model.

2