10 Version 1.3

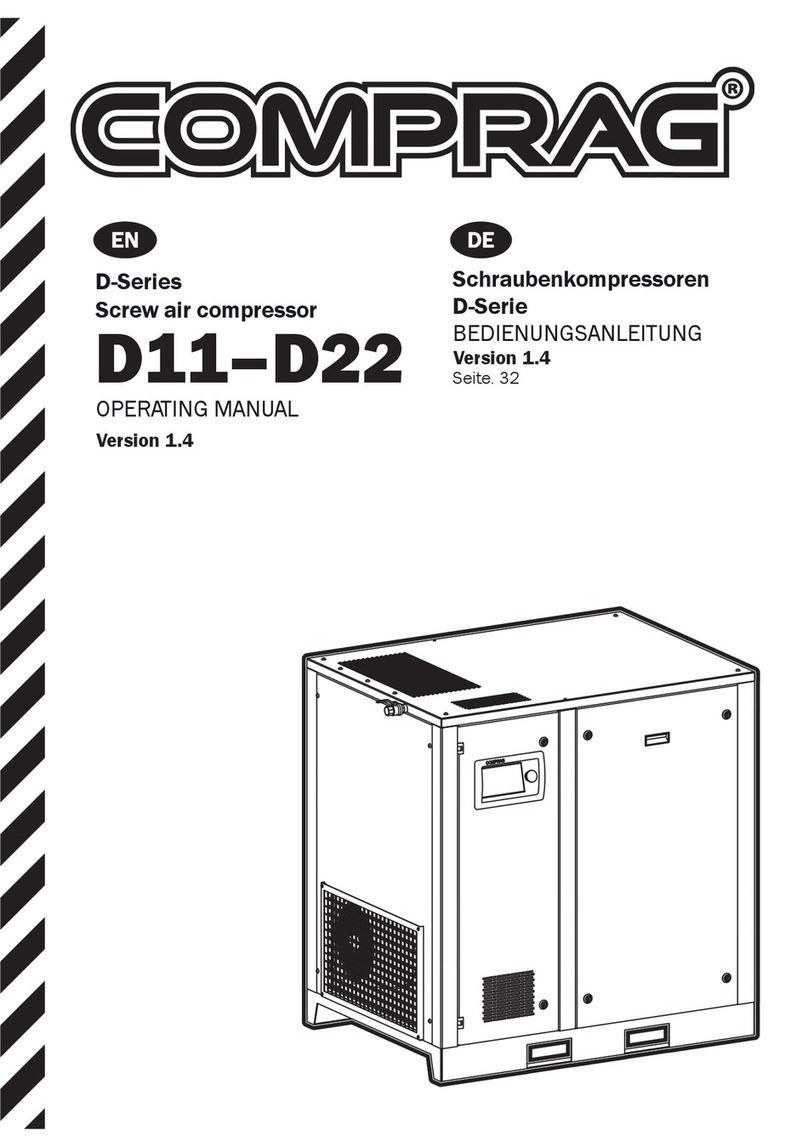

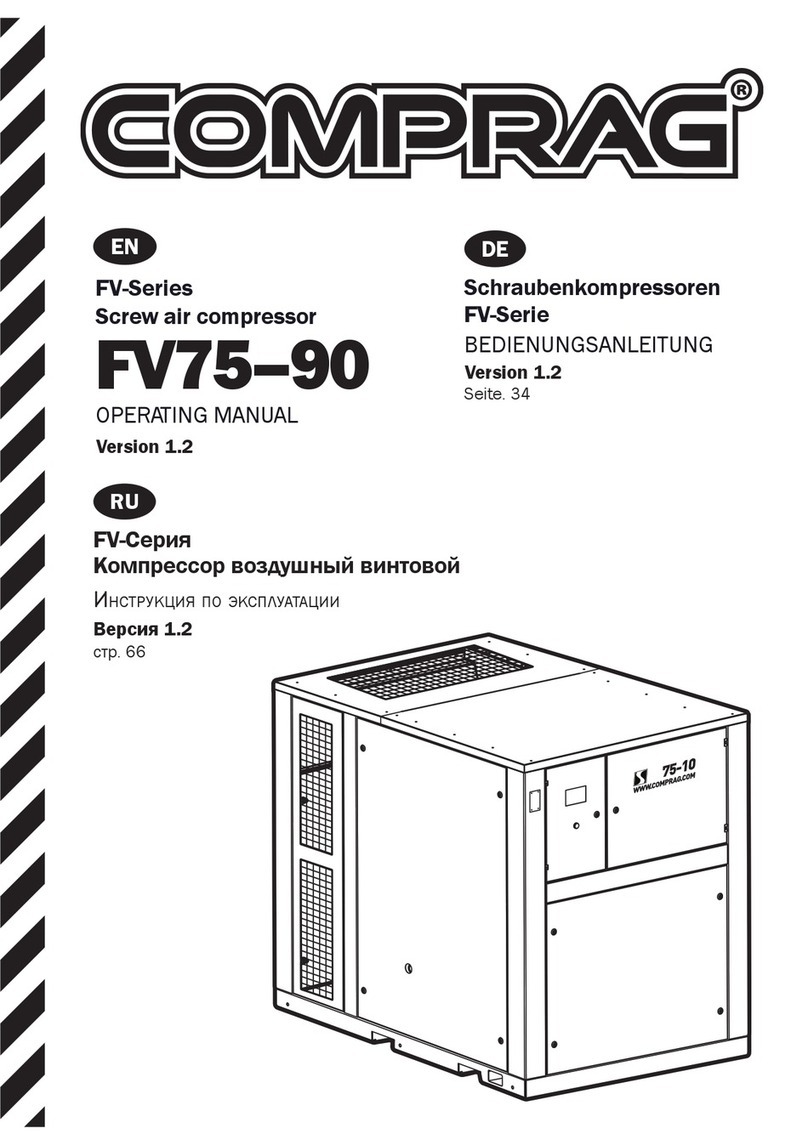

2.4 Functional description (see Fig. 2.3)

Air ow: Air drawn through Air

lter

(4) and open Intake valve (5) into compressor Air-end (3) is

compressed. Compressed air and oil ow into Air-Oil separation tank (6). The air is discharged

via Min. Pressure valve (11) through Heat-exchanger (13) towards the Air Outlet Valve (20).

Oil ow: Air pressure forces oil from the air-oil separation tank (6) through the heat-exchang-

er (14) and the oil lter (16) to the compressor air-end (3) and the lubrication points. In the

air-oil separation tank (6), most of the oil is removed centrifugally; the rest is removed by

the air-oil separator (8). The oil system is tted with a thermostatic valve (15). When the oil

temperature is below the set-point of the thermostatic valve, the thermostatic valve shuts

off the oil

su

pply

from

oil heat-exchanger (14). The thermostatic valve starts opening the

supply from heat- exchanger (14) when the oil temperature exceeds the valve’s setting. The

setting of the thermostatic valve depends on the model. See table Technical Data.

Cooling system: The cooling system is a combined radiator consisting of a part for air (13) and a

part for oil (14). The ventilation takes place with a fan with separate electric motor.

2.5 Regulating system

The system is controlled by an electronic controller v-Log (2) which keeps the net pressure

within programmable pressure limits by automatically loading and unloading the compressor

in relation to air consumption.

Main operating mode: Upon start-up, the frequency inverter accelerates the compressor over

15 seconds to the maximum permitted frequency. Pressure builds up to the specied target val-

ue. When it is reached, the compressor maintains the set pressure by varying the current signal

coming from the frequency inverter. If the consumption of compressed air increases, the frequency

coming from the frequency inverter also increases and thus the rotation of the main motor shaft. If

the consumption of compressed air decreases, the frequency coming from the frequency inverter

also decreases. However, the compressed-air pressure remains constant. When the off button is

pressed, the frequency inverter lowers the frequency over 15 seconds to the minimum permitted

frequency and switches off the compressor.

Unloading: If air consumption is less than the air delivered by the compressor, the net pressure

increases. When the net pressure reaches the upper limit of working pressure (unloading

pressure), the solenoid valve (3) is de-energized. The damper (5) of the intake valve (1) closes

the air inlet opening by a spring force:

1. The control pressure present in the chambers of the intake valve (1) and the unloading

valve (7) is vented into the atmosphere via the solenoid valve (3).

2. The damper (5) of the intake valve (1) closes the air inlet opening.

3. The unloading valve (7) is opened by the air-oil separation tank pressure. The pressure

from the air-oil separation tank (4) is released towards the air inlet.

4. The pressure is stabilized at a low value, air output is stopped (0 %) and the compressor

runs unloaded.