8. Technical data

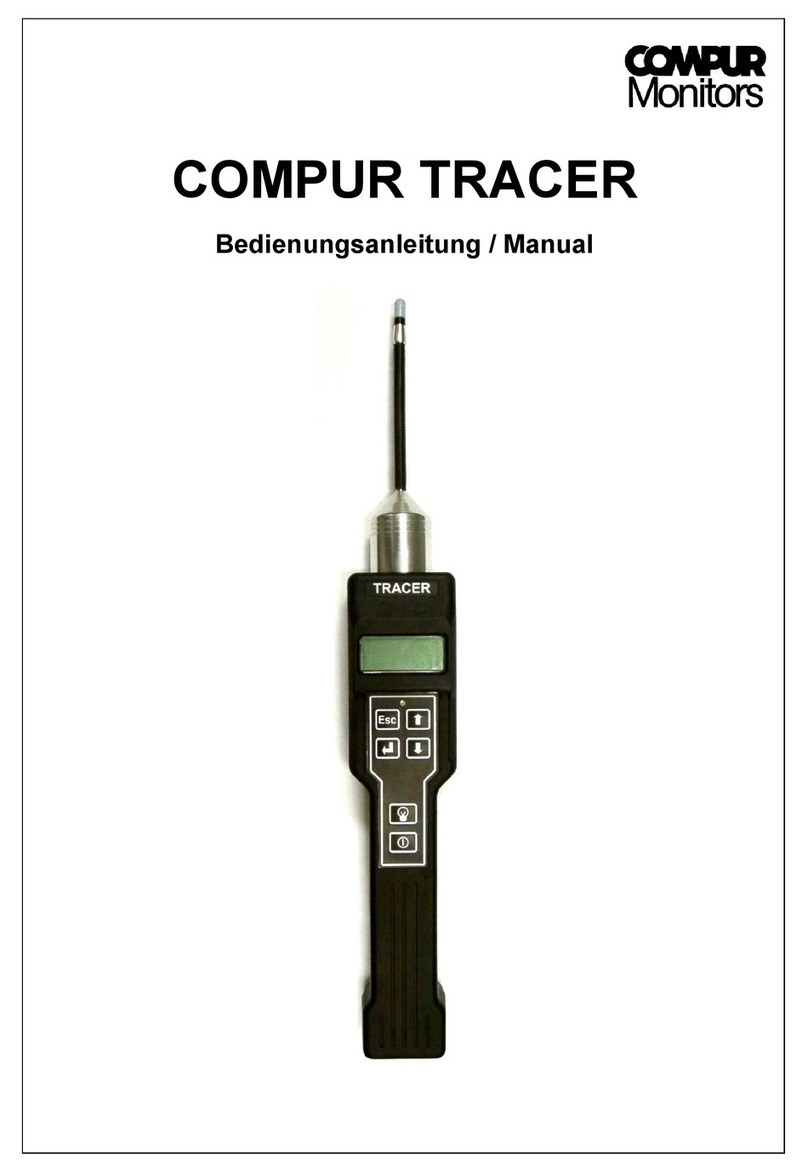

Type: 5306 500

Manufacturer: Compur Monitors, München

Protection class: EEx ib IIC T6

Operating environment: II 2 G

Operating temperature: -20°C to +50°C ( -4°F to + 122°F)

Power supply: 2 x Li, 3V:

only CR 2477N (Renata) or CR 2477 (Panasonic)

Sensor principle Electrochemical

Humidity typ.: 20% to 90% r.h.

Pressure 920 hPa – 1120 hPa

Display 4-digit LCD-Display

Weight 130 g (4,6 oz)

Dimensions (With filter cap) 4,9 x 2,6 x 1“

Battery lifetime about 800 hours

Alarm thresholds adjustable range 0 – 100% of range

Alarms loudness typ.: 80 db (A) / 30 cm

Terminal Earphone

Sensor warranty 6 to 12 months

Specifications are subject to change without notice, and are provided only for comparison of products.

The conditions, under which our products are used, are beyond our control. Therefore, the user must

fully test our products and/or information to determine suitability for any intended use, application,

condition or situation. All information is given without warranty or guarantee. Compur Monitors disclaims

any liability, negligence or otherwise, incurred in connection with the use of the products and information.

Any statement or recommendation not contained herein is unauthorized and shall not bind Compur

Monitors. Nothing herein shall be construed as a recommendation to use any product in conflict with

patents covering any material or device or its use. No licence is implied or in fact granted under the

claims of any patent. Instruments are manufactured by Compur Monitors GmbH & Co. KG, Munich.

The General Conditions of Supply and Service of Compur Monitors GmbH & Co. KG are applicable.

5306 500 998 07 00 / 05.05 506110

9