Contents

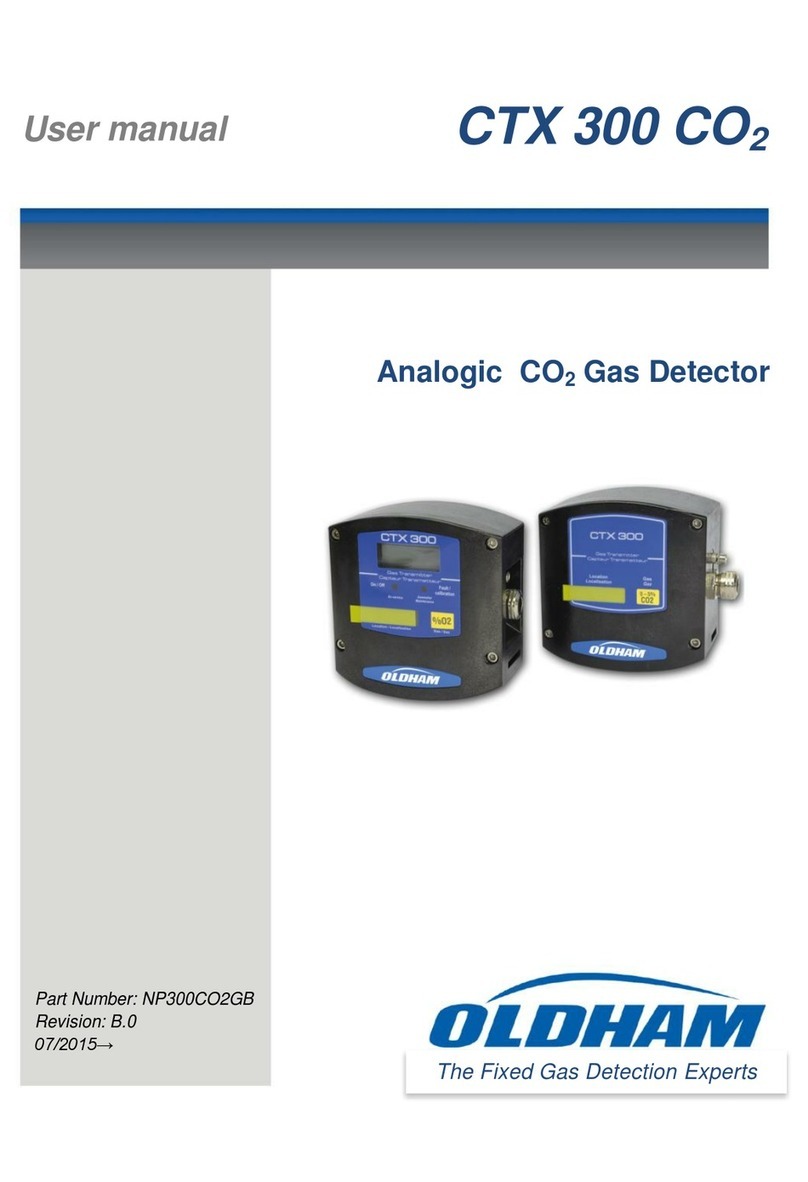

Chapter 1 | Overview..............................................................7

Purpose......................................................................................................7

Composition of the Detector Assembly......................................................7

Type of detector available..........................................................................8

Chapter 2 | Installation...........................................................9

Regulations and conditions of use.............................................................9

Location of the detector..............................................................................9

Detector positioning ...................................................................................9

Connection...............................................................................................10

Configuration of communication ..............................................................12

Scope of use............................................................................................14

Chapter 3 | Maintenance ......................................................15

Maintenance Frequency...........................................................................15

Semi-automatic calibration.......................................................................16

Sensor replacement.................................................................................18

Manual calibration....................................................................................20

Chapter 5 | Spare Parts........................................................25

Chapter 6 | UE Declaration...................................................27

Chapter 7 | Specifications....................................................29

Detector....................................................................................................29

Sensor specifications ...............................................................................30

Line length (use with MX 32) ...................................................................32

Line length (use with MX 43) ...................................................................35

Chapter 8 | Specific instructions for use in explosive

atmospheres in accordance with European ATEX Directive

94/9/EC 39

General comments...................................................................................39

Marking for LEL versions .........................................................................39

Marking for toxic gas or oxygen detector versions (except CO2versions)

40