Statox 560 Getting started

Page 10 of 10 Issue 12/2016

7Technical Data

Product name: Statox 560

Type: 5377

Manufacturer: COMPUR Monitors GmbH & Co. KG, Weissenseestr. 101,

D-81539 Munich

Power supply: 24 (16-30) VDC

Power consumption: max. 2.7 W (8.7 W for COCl2) at input voltage ≤ 26 VDC

Operating temperature: -30°C to +60°C

Storage temperature: -30°C to +60°C

Pressure: 700 to 1300 hPa

Humidity: 0% to 99% r. H. (non condensing)

Application: II 2G

Explosion protection: Ex d ib IIC T4 Gb (at Um= 30 VDC for all connections)

EC type examination certificate: BVS 16 ATEX E 065 X (X: the measuring function according Annex II, point

1.5.5 of directive 2014/34/EU is not part of the EC type examination certificate.)

Protection class EN60529: IP 66 (gas intake IP54)

Display: 2 x 16 signs, illuminated

Housing: Cast aluminum epoxide varnished / stainless steel

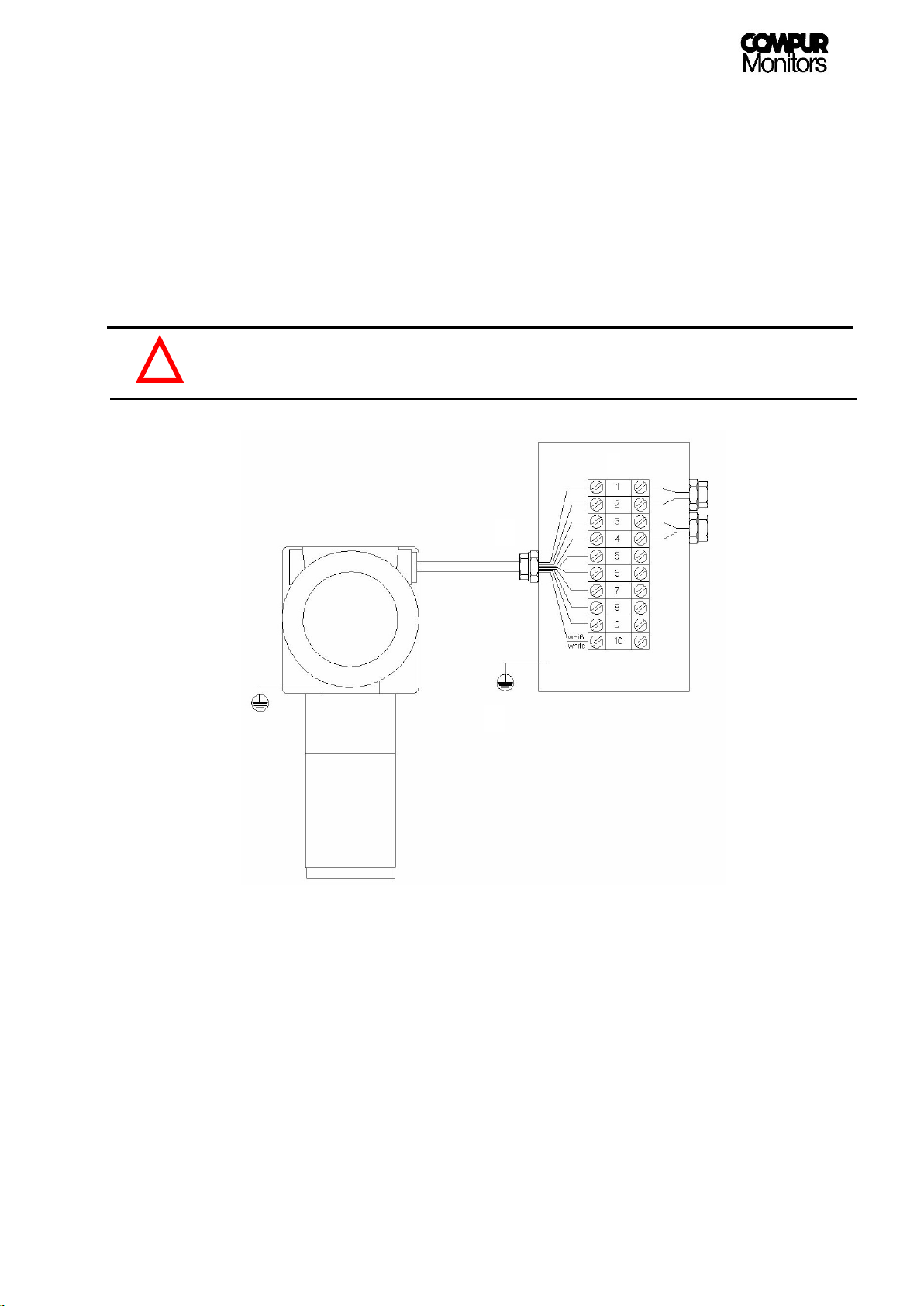

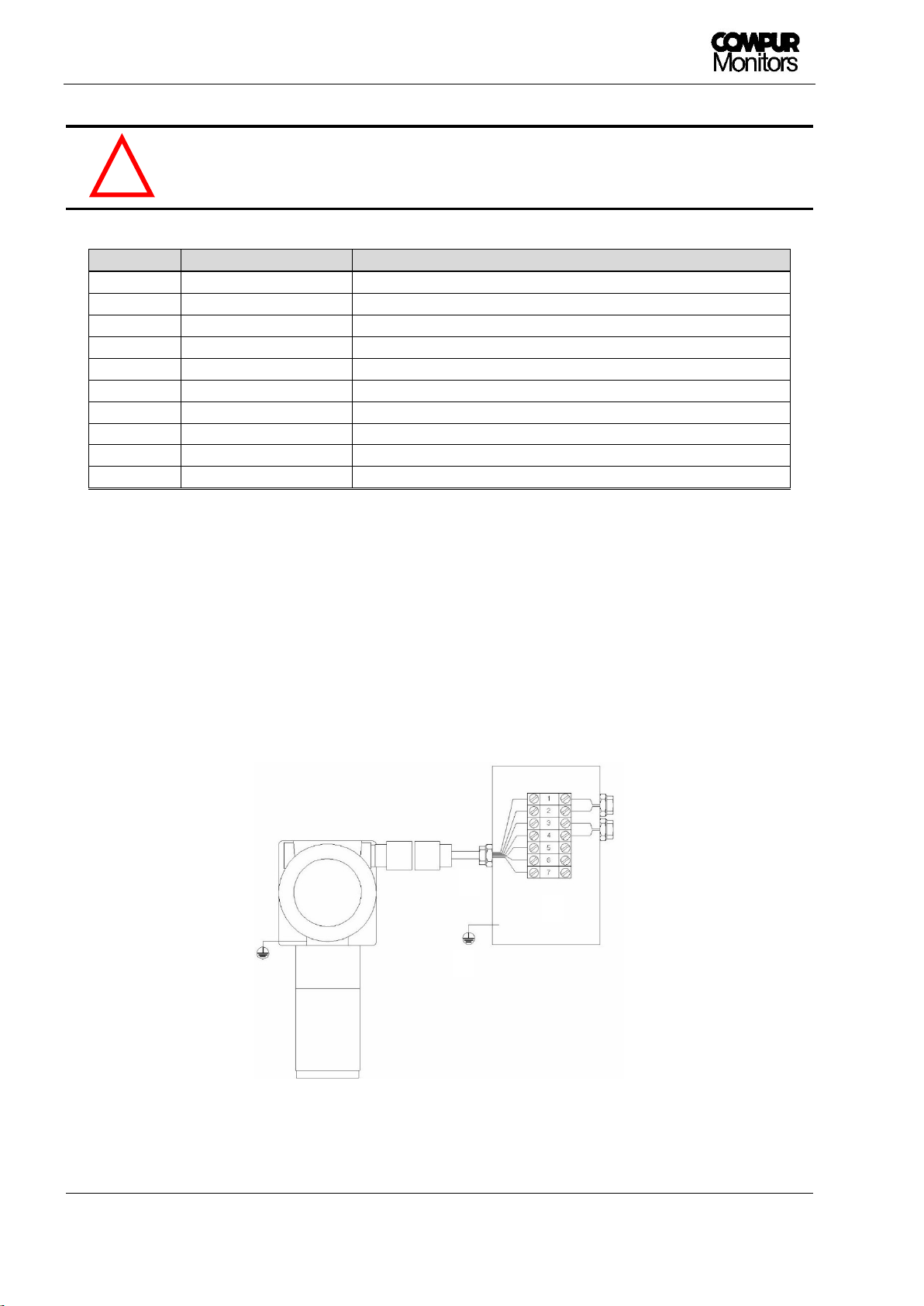

Connections: 10-core cable tail (1 m) or 7-pin eXLink plug

Open-Drain-outputs: 2 x alarm, 1 x system failure, 1 x maintenance request

Characteristic values max. 30 VDC / 2.5 A

SF-Open-Drain- output: In normal operation active (conductive)

Analog output: 0 mA in case of system failure

2 or 4 mA in the service mode, programmable

4 - 20 mA in the measuring mode

22 mA when full scale is exceeded

max. burden: 450 Ohm

EMC: EN 61000-6-4:2007 + A1:2011 / EN 50270:2015 (type 2)

Functional safety: SIL 2 compliant according to IEC 61508:2010

Automatic self-test: every 24 hours, time is selectable

Weight: ca. 4800 g

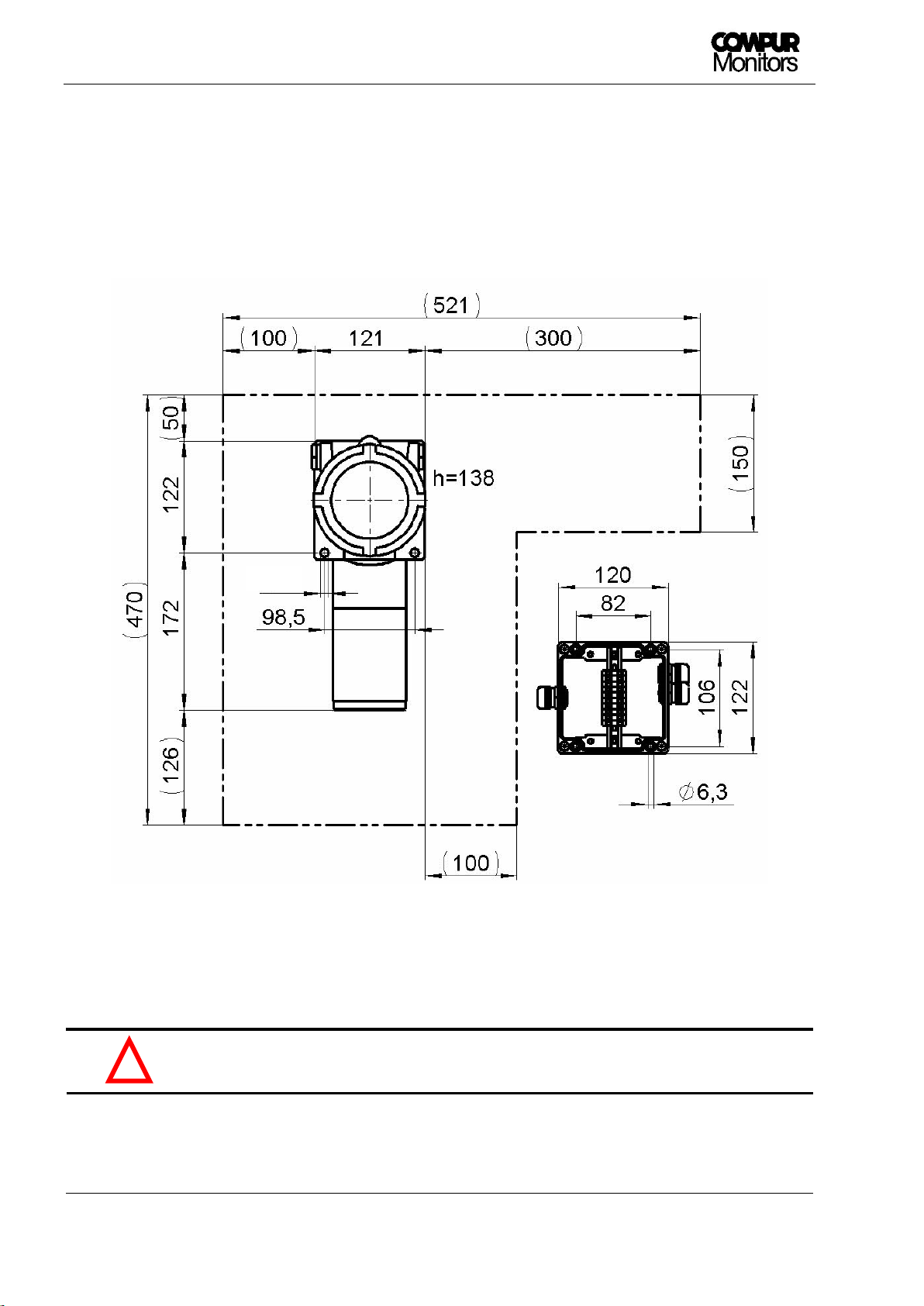

Dimensions: 121 x 294 x 138 mm (W x H x D)

Compur Monitors GmbH & Co. KG

Weißenseestraße 101

D-81539 München

Phone 0049 (0) 89 62038 268

Fax 0049 (0) 89 62038 184

Internet: www.compur.com

E-Mail: compur@compur.de

5377 000 997 07 01 562992

Specifications are subject to change without notice, and are provided only

for comparison of products. The conditions under which our products are

used, are beyond our control. Therefore, the user must fully test our

products and / or information to determine suitability for any intended use,

application, condition or situation. All information is given without warranty

or guarantee. Compur Monitors disclaims any liability, negligence or

otherwise, incurred in connection with the use of the products and

information. Any statement or recommendation not contained herein is

unauthorized and shall not bind Compur Monitors. Nothing herein shall be

construed as a recommendation to use any product in conflict with patents

covering any material or device or its use. No license is implied or in fact

granted under the claims of any patent. Instruments are manufactured by

Compur Monitors GmbH & Co. KG, Munich. The General Conditions of Supply

and Service of Compur Monitors GmbH & Co. KG, Munich, are applicable.