8 Technical Data

Instrument name, type: Statox 506 Transmitter Type 5376

Manufacturer: COMPUR Monitors GmbH & Co. KG, D-81539 München

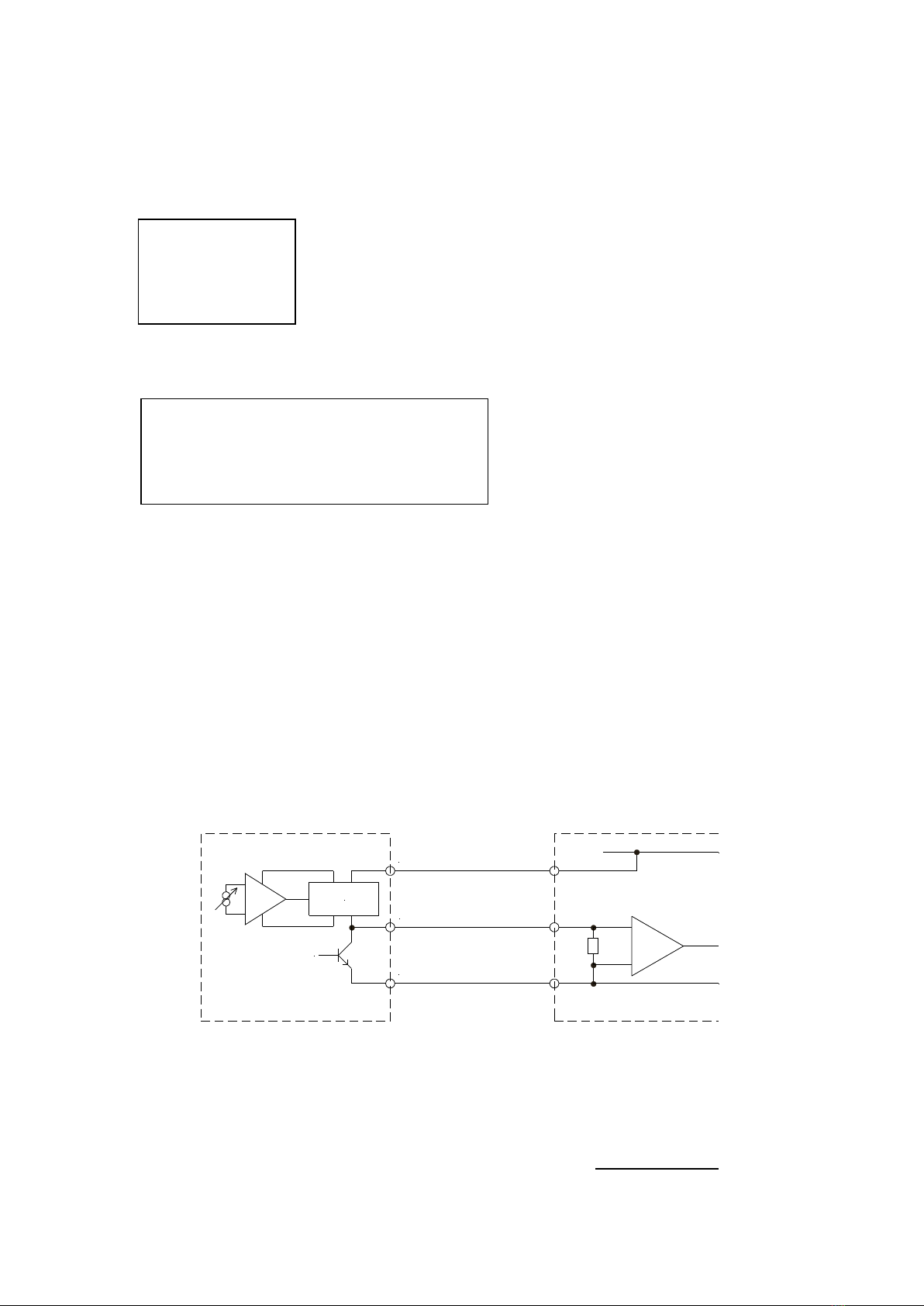

Measuring principle: electrochemical

Operation temperature: -30°C to +60°C ambient air temperature

Storage temperature: -30°C to +60°C

Humidity: 0 to 99% r.F. (non condensing)

Pressure: 900 to 1100 hPa

Accuracy at calibration concentration: ± 10%

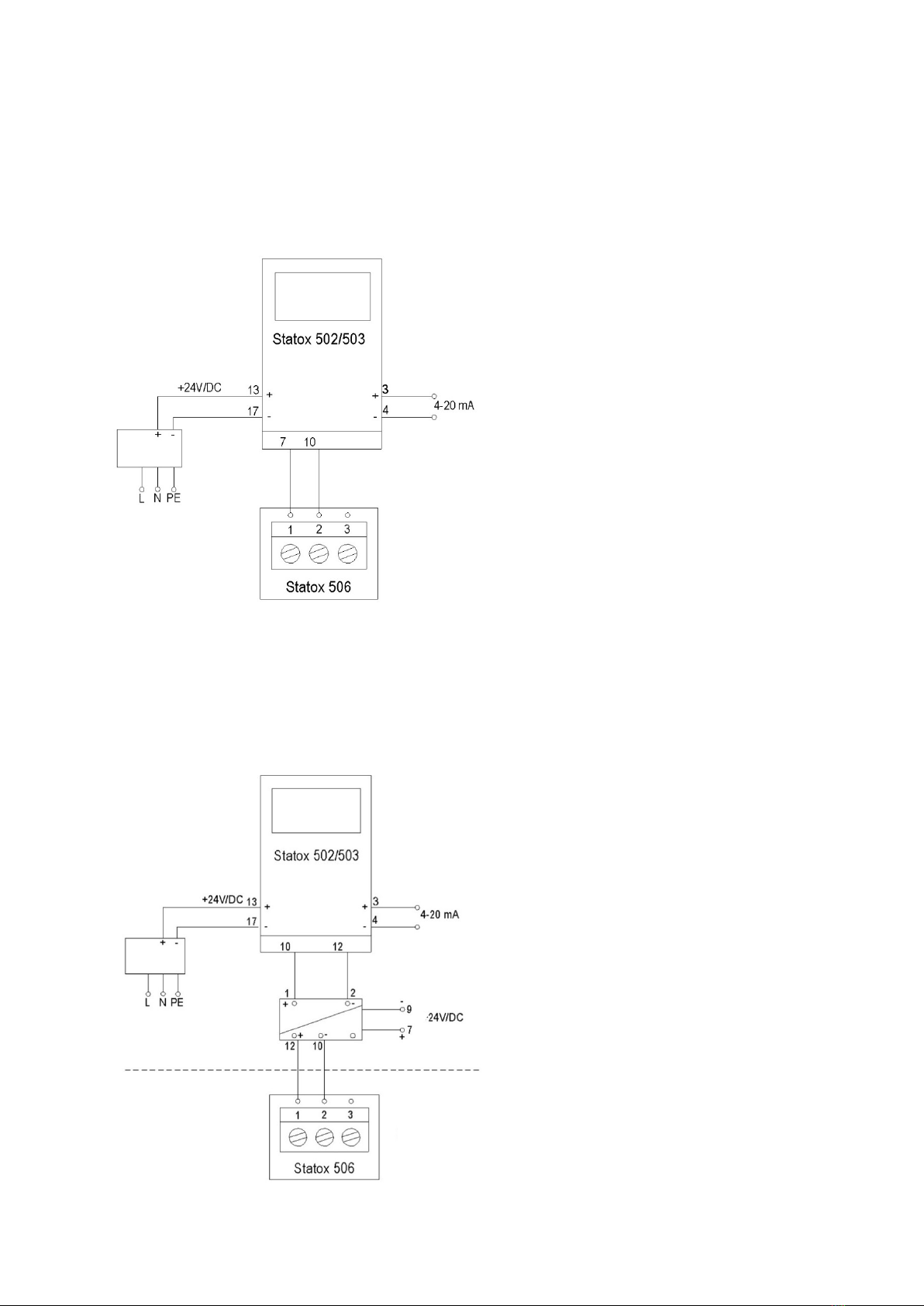

Power supply: 24 VDC (12 -28 VDC)

Connections: 2- or 3-wire operation

Terminal width: 0.25 –2.5 mm² (AWG 24 –12)

Output: 0 - 22 mA, max. load 545 Ohm

Service mode: 2 or 4 mA adjustable

System failure: 0 mA 3-wire operation, 2 mA 2-wire operation

Overrange: 22 mA

Display: 8-digits, 14 segments

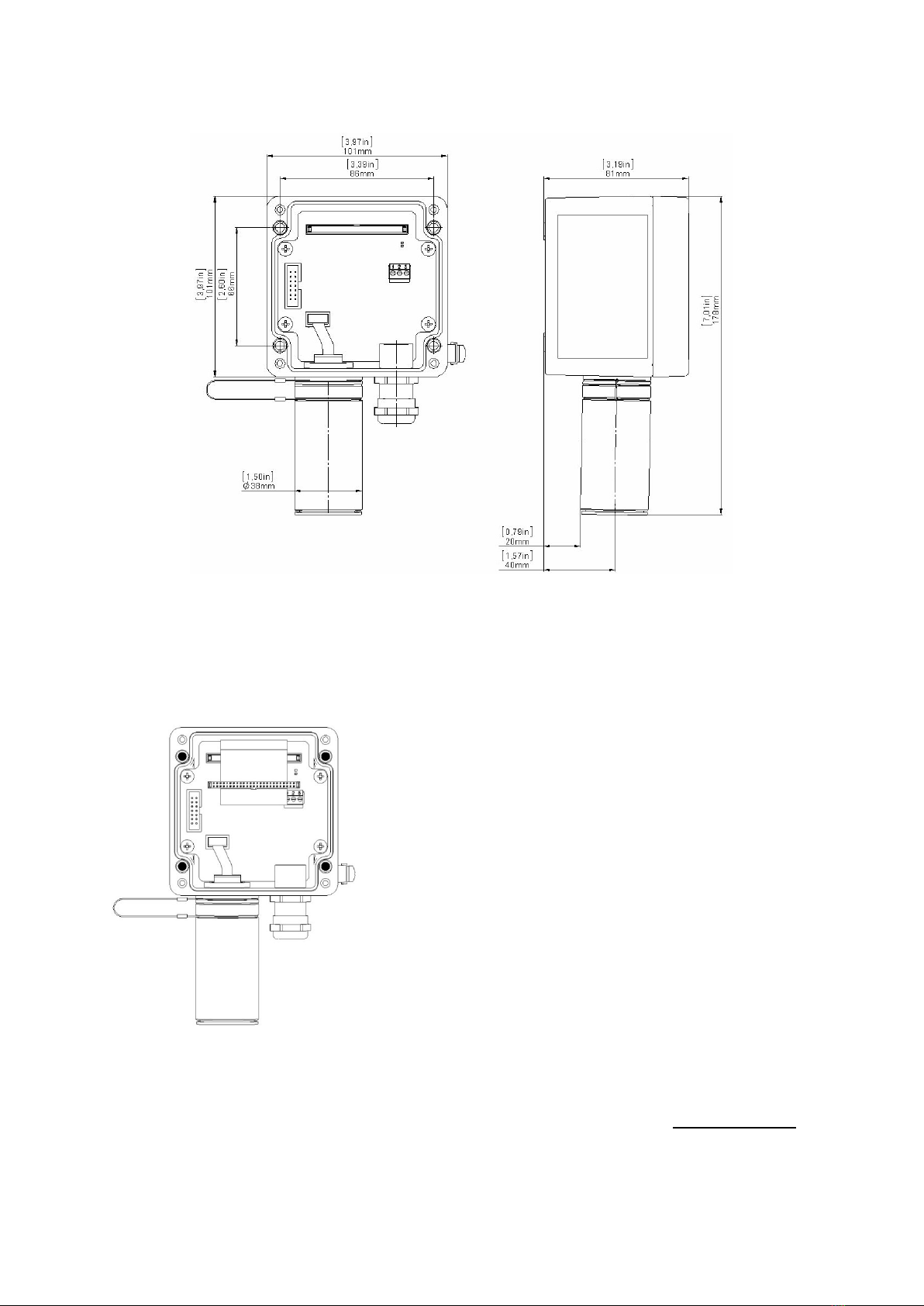

Dimensions (HxWxD): 180 x 111 x 81 mm

Weight: ca. 1200 g

Housing material: Cast aluminium, enameled / stainless steel

Ingress protection EN 60529: IP 66

Installation: Sensor downwards

EMV: EN 50270

ATEX marking: Ex ib IIB T4 Gb

Application: II 2G

Approval: BVS 18 ATEX E 066 X / N2

(X- Marking: requires potential equalization along the intrinsically safe loop)

Power supply Ui :max. 28 VDC

Current Ii : max. 93 mA

Power Pi: max. 650 mW

Internal capacity Ci : 24 nF

Internal Inductivity Li : neglectable

Functional safety: SIL 2 compliant with IEC 61508

Please find the sensor specifications in the detailed manual on our homepage www.compur.com !

Specifications are subject to change without notice, and are provided only for comparison of products. The conditions under which

our products are used, are beyond our control. Therefore, the user must fully test our products and / or information to determine

suitability for any intended use, application, condition or situation. All information is given without warranty or guarantee. Compur

Monitors disclaims any liability, negligence or otherwise, incurred in connection with the use of the products and information. Any

statement or recommendation not contained herein is unauthorized and shall not bind Compur Monitors. Nothing herein shall be

construed as a recommendation to use any product in conflict with patents covering any material or device or its use. No licence is

implied or in fact granted under the claims of any patent. Instruments are manufactured by Compur Monitors GmbH & Co. KG,

Munich. The General Conditions of Supply and Service of Compur Monitors GmbH & Co. KG, Munich, are applicable.

5376 000 997 07 00 / 02.21 516238

Compur Monitors GmbH & Co. KG

Weißenseestraße 101

D-81539 München

Tel.: ++49/89/ 6 20 38 268

Fax : ++49/89/ 6 20 38 184

http://www.compur.com

E-Mail: compur@compur.de