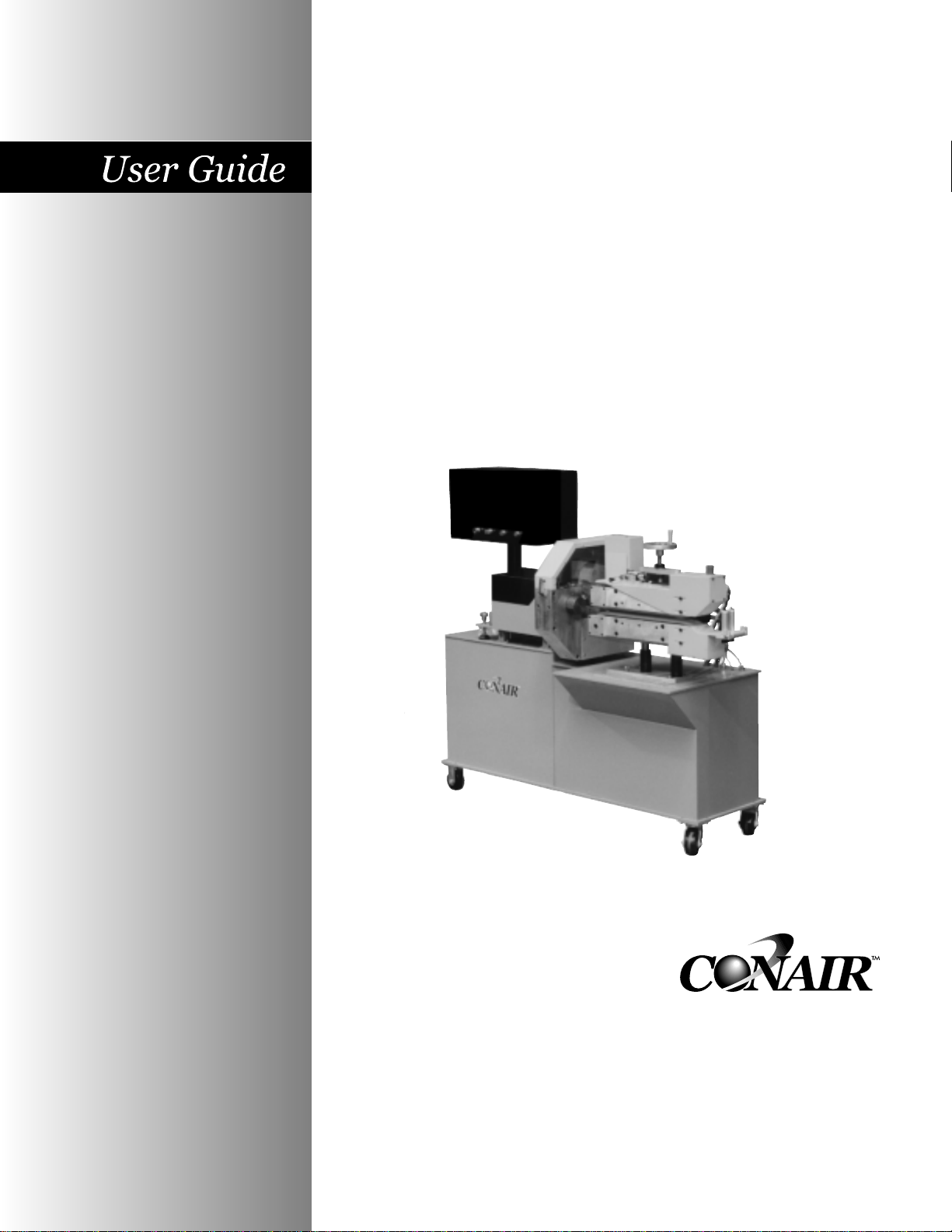

CSC Combination Puller/Cutter UGE048/1103

OPERATION . . . . . . . . . . . . . . . continued

Cutter Control Instructions Min. Measurements . . . . . . . .4-17

Cutter Control Instructions Maintenance Area . . . . . . . . .4-17

Cutter Control Instructions Encoder Area . . . . . . . . . . . . .4-18

Cutter Control Instructions Encoder Direction . . . . . . . . .4-19

Cutter Control Instructions Unit of Measure . . . . . . . . . . .4-20

Cutter Control Instructions Scale Distance . . . . . . . . . . . .4-21

Cutter Control Instructions Scale Counts . . . . . . . . . . . . .4-22

Cutter Control Instructions Homing . . . . . . . . . . . . . . . . .4-23

Cutter Control Instructions Home Offset . . . . . . . . . . . . .4-23

Cutter Control Instructions Offset Example . . . . . . . . . . .4-24

Cutter Control Instructions Power on Time . . . . . . . . . . .4-25

Puller Operation Control . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Stopping the Puller . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

Shutting the Puller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

Before starting the Combination unit . . . . . . . . . . . . . . . .4-29

Powering up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-30

Programming the Puller Speed . . . . . . . . . . . . . . . . . . . . .4-30

Setting the Cutting Mode . . . . . . . . . . . . . . . . . . . . . . . . .4-31

Setting the Scale Factor . . . . . . . . . . . . . . . . . . . . . . . . . .4-32

Checking the Cut Quality . . . . . . . . . . . . . . . . . . . . . . . . .4-32

Start-ip Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

Starting the Puller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-35

Making Adjustments during operation for the Cutter . . . .4-36

Making large changes to the Puller Speed . . . . . . . . . . . .4-37

Stopping only the Cutter . . . . . . . . . . . . . . . . . . . . . . . . .4-37

Stopping the Combination unit . . . . . . . . . . . . . . . . . . . . .4-38

Shutting down the Combination unit . . . . . . . . . . . . . . . .4-38

MAINTENANCE . . . . . . . . . . . . . . . . . . . .5-1

Maintenance Features . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Preventative Maintenance Schedule . . . . . . . . . . . . . . . . . .5-4

Inspecting Cutter Blades . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Inspecting Blade Hardware . . . . . . . . . . . . . . . . . . . . . . . .5-6

Inspecting Cutter Bushing Screws . . . . . . . . . . . . . . . . . . .5-7

Checking the Closure Latch . . . . . . . . . . . . . . . . . . . . . . . .5-7

Checking Floor Locks . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Cleaning the Lubrication Tray . . . . . . . . . . . . . . . . . . . . . .5-8

Lubricating the Slide Rail . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Checking Grease Locations . . . . . . . . . . . . . . . . . . . . . . . .5-9

Adjusting the Cutter Proximity Switches . . . . . . . . . . . . .5-10

Checking Electrical Connections . . . . . . . . . . . . . . . . . . .5-11

Testing Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Checking the Belt Gap . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Replacing Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

Checking Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

ii

TABLE OF

CONTENTS