8

2.2 INSTALLATION PROCEDURE

1. Site the Smoke Screen and fix to the wall or ceiling as appropriate.

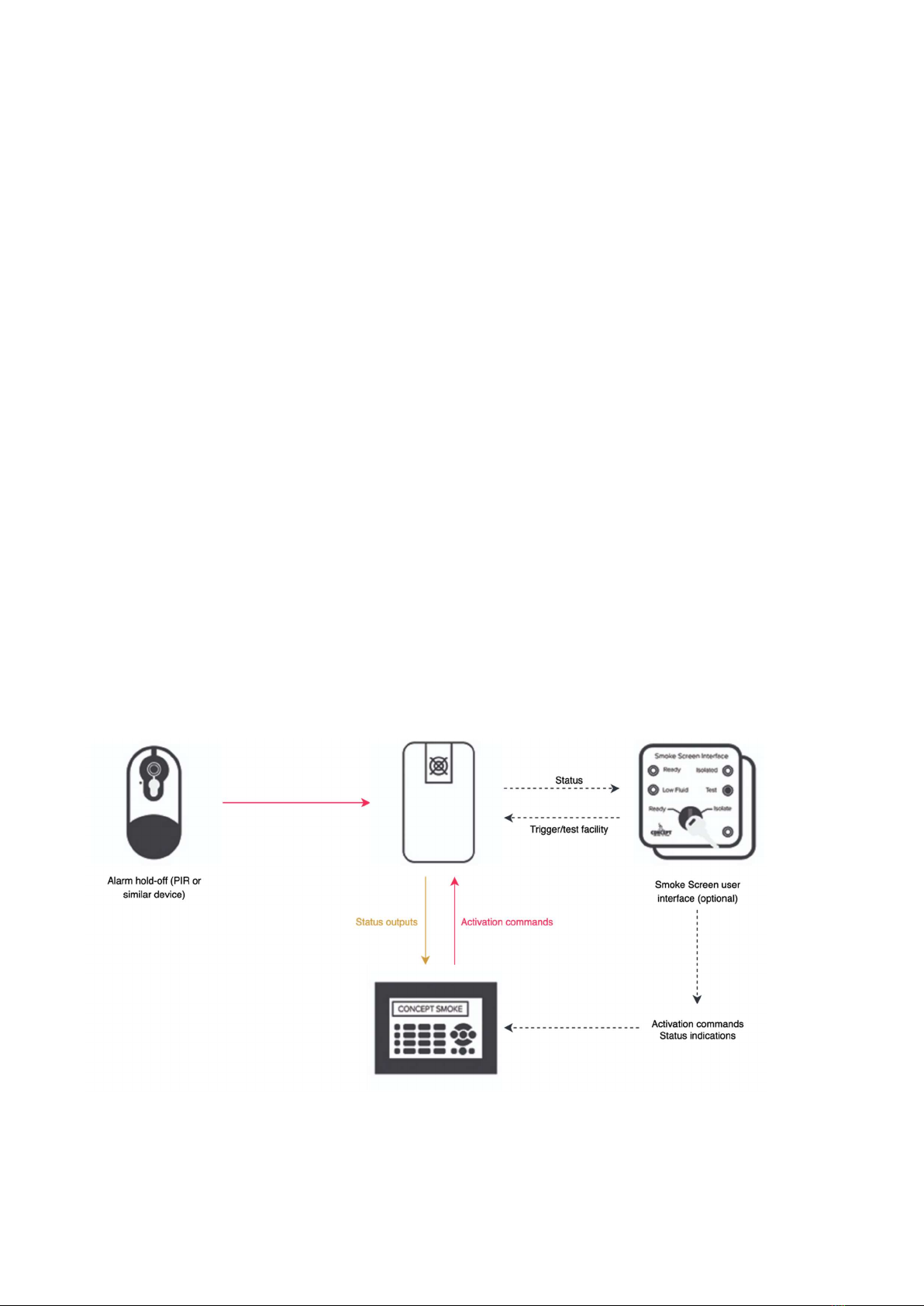

2. Make connections as required to the alarm panel, SSI, hold-off PIR, and PA.

3. Fit batteries, do not switch on yet.

4. If fitted, set the Smoke Screen Interface to ‘isolate’.

5. Select the ‘Service Mode’ dip switch to ‘On’.

6. Change nozzle, if required, before powering up.

7. Connect and turn on the mains power.

8. Turn on the internal battery back-up switch.

9. The Smoke Screen will heat up to operating temperature in approximately 10-15 minutes.

10. Set correct time/date.

11. Set correct smoke timing for the specified room size.

12. if using a Sentinel+, connect an ethernet cable to the module and follow setup instructions.

13. Insert a fluid consumable.

14. Visually test all signals between the Smoke Screen, alarm panel, SSI, hold-off PIR, and PA (as fitted).

15. Confirm alarm panel has full control of the Smoke Screen. With SSI in ‘Ready’ position if fitted.

16. Ensure the ‘Service Mode’ dip switch is selected to ‘Off’.

17. Make sure all tamper switches are closed.

18. Perform activation test.

19. Final check of settings and monitored signals, SSI in ‘Ready’ position if fitted.

2.3 ACCESS

To access the PCB connections, programming panel, mounting holes, batteries, and fluid, remove the front cover by

unscrewing the set screws on either side and unhooking it from the back plate; refitting is the reverse process.

Installation cable entry is through the serrated grommet on the left side of the back plate.

2.4 MOUNTING

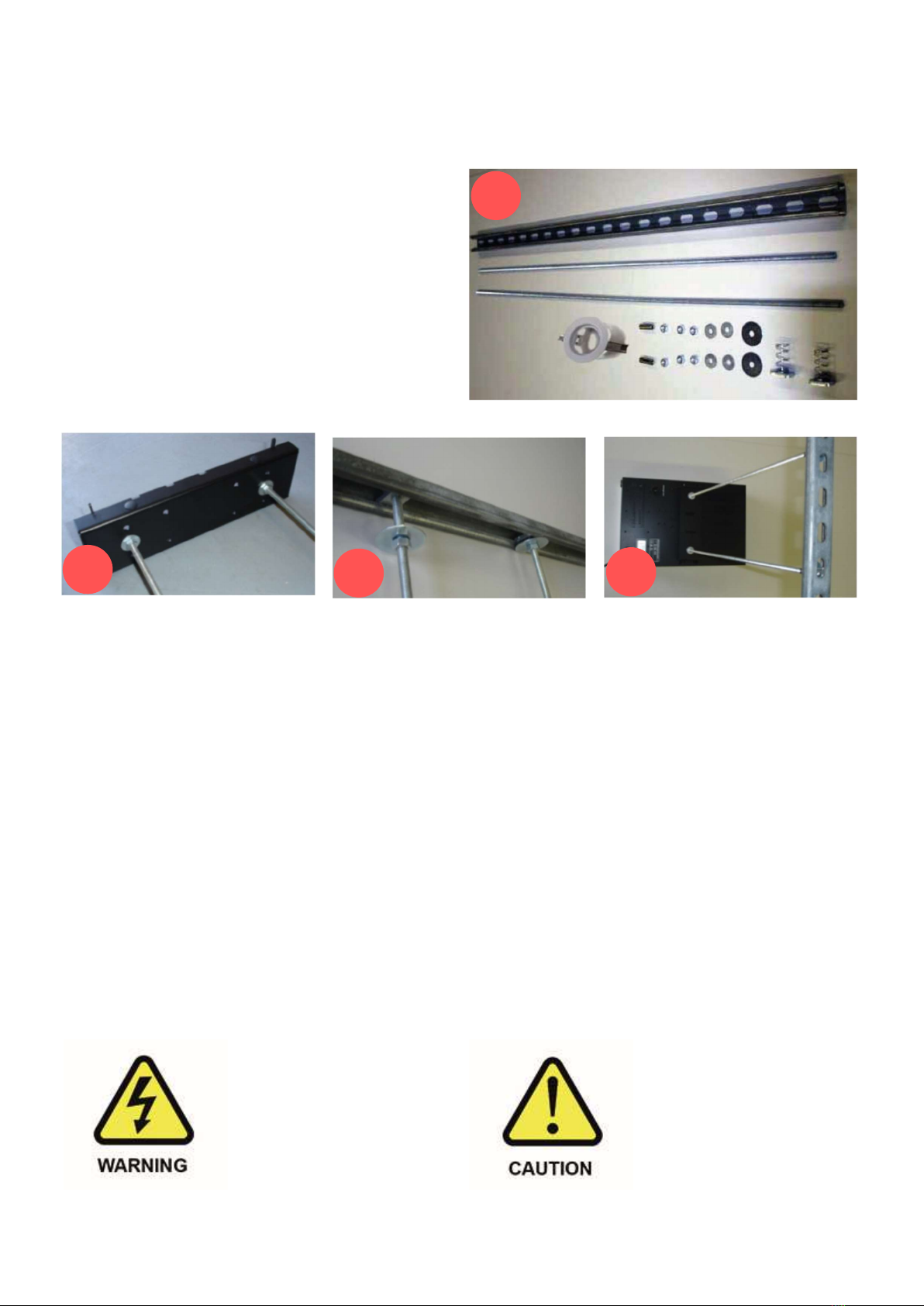

The Smoke Screen can be mounted on a ceiling or a wall using the simple standard bracket supplied with the unit.

This flush-fitting bracket maximizes security by concealing all the mounting fastenings such that they can only be

accessed, or the Smoke Screen dismounted, by dismantling the unit. Moreover, the Smoke Screen has a tamper

protection switch to provide an alert in the unlikely event that it is disturbed. In all cases, the installer must attach the

Smoke Screen to the building structure using appropriate fasteners.

NB: When mounting the Smoke Screen ensure that the airflow through the vent holes in the rear of the unit is not

obstructed.

Wall and ceiling mounting

Ceiling or wall mounting is the same process except that rather than fixing the Smoke Screen direct to a ceiling an

intermediate unistrut section may be used or it can be suspended as described in the next section.

a c

b