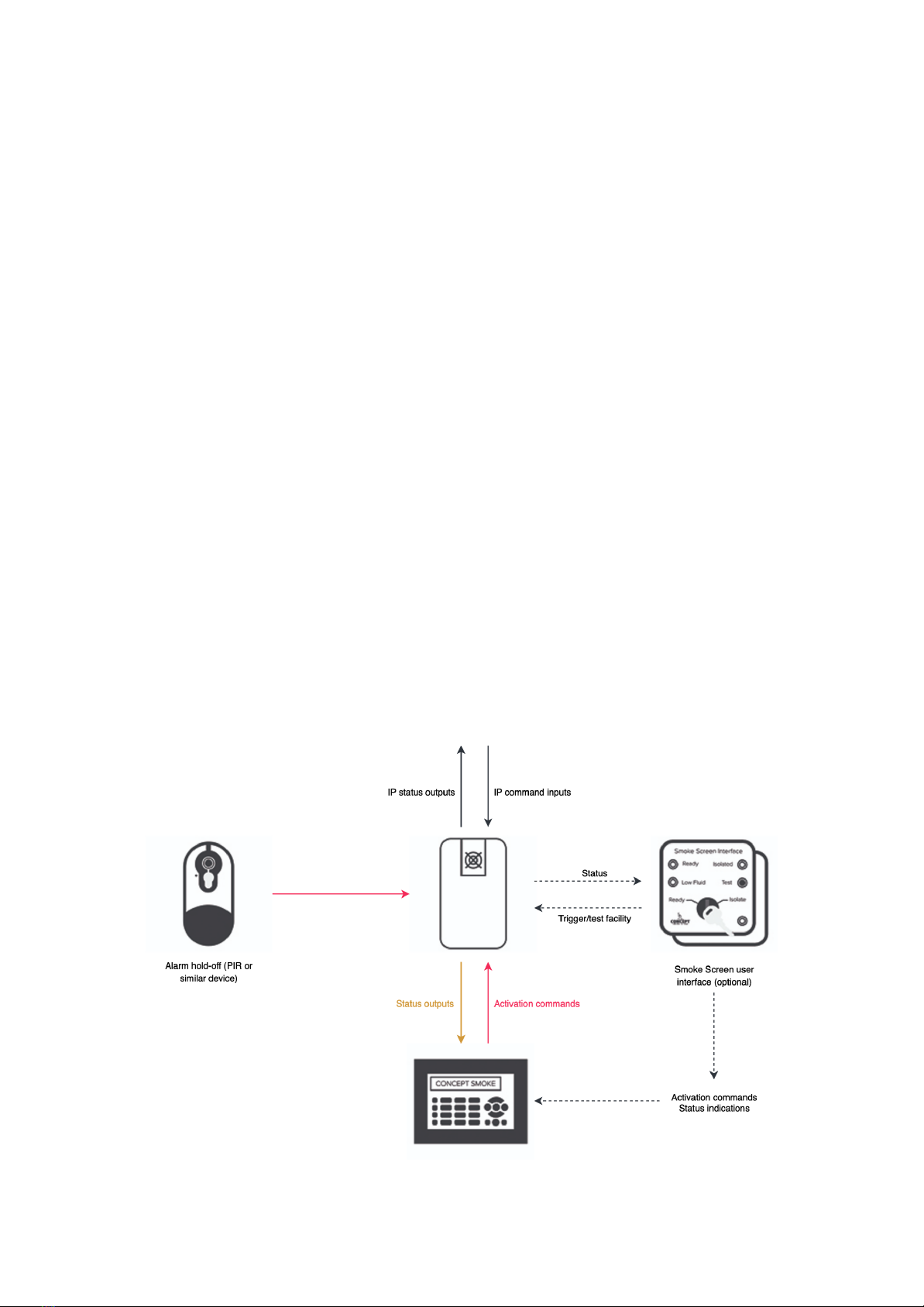

A Smoke Screen system can be installed in many ways; the following are outlines of typical installations

(an Alarm Panel Control system is generally used for illustration in this manual):

Alarm Panel Control

●The Smoke Screen is wall or ceiling mounted in the appropriate location.

●A Hold-off PIR (or similar device) located within the same area as the Smoke Screen providing a

confirmation signal to the Smoke Screen to start, or restart, ‘smoke’ production.

●A Set command supplied by an alarm control panel, or equivalent, in the form of an N/C (normally

closed) or an N/O (normally open) relay changing state when the alarm system is set for operation.

●A Trigger command supplied by the alarm control panel, or equivalent, in the form of an N/C

(normally closed) or an N/O (normally open) relay changing state when the alarm system confirms

an intruder alert.

Local Network Monitoring

●The Smoke Screen is wall or ceiling mounted in the appropriate location.

●Typically, the Smoke Screen would be integrated with an alarm panel or similar controlling system

as above.

●The Smoke Screen is assigned a fixed or reserved IP address and attached to the local network.

●The addition of the TitanConfig program running on the same network will allow diagnostic and

configuration control from a Windows-based platform.

Remote Network Monitoring and Control

●The Smoke Screen is wall or ceiling mounted in the appropriate location.

●The Smoke Screen may be integrated with an alarm panel and/or commanded from a central

location over IP.

●The Smoke Screen is assigned an IP address on the local network and communicates with a

centralised remote server using ports 161 & 162.

●The Smoke Screen may be controlled using any third party platform integrated with TitanServer or

through the Titanium247 cloud-based monitoring and control platform. Finally, engineering control

and diagnostics are offered through TitanConfig.