1

Coating thickness gauge

EN User manual 1

DE Bedienungsanleitung 1

R U Р у к о в о д с т в о п о л ь з о в а т е л я 2

Толщиномер покрытий

Schichtdickenmessgerät

PAINT

User manual

Coating thickness gauge

EN

Congratulations on your purchase of coating thickness gauge

PAINT CONDTROL.

Safety instructions provided in this user manual should be

carefully read before you use the product for the first time.

SAFETY REGULATIONS

Attention! This user manual is an essential part of this product.

The user manual should be read carefully before you use the

product for the first time. If the product is given to someone

for temporary use, be sure to enclose user manual to it.

- Do not misuse the product

- Store the product beyond reach of children and unauthorized

people.

- It is prohibited to disassemble or repair the product yourself.

Entrust product repair to qualified personnel and use original

spare parts only.

- Do not use the product in explosive environment, close to

flammable materials.

- Avoid heating the batteries to avoid the risk of explosion and

electrolyte leakage. In case of liquid contact with skin, wash

it immediately with soap and water. In case of contact with

eyes, flush with clean water during 10 minutes and consult the

doctor.

FUNCTIONS/APPLICATIONS

Coating thickness gauge PAINT CONDTROL is intended for

fast, accurate and non-destructive measurement of thickness

of non-magnetic coatings (paint, film) applied on metal

surface in the range 0 – 1.80 mm. This device can be widely

used in manufacturing, metal processing, chemical industry,

commodity inspection, cars quality control, etc.

The principle of operation is based on interaction of the

sensor which emits electromagnetic pulses with metal. The

strength of the pulse reflected from the metal depends on

the thickness of the paint coating. The instrument calculates

the power of the reflected signal and compares it with the

data stored in the memory. As a result, the display shows the

thickness of coating in millimeters with 0.01 mm accuracy.

EN

Functions:

1) Measurement of coating thickness on metal surface.

2) Single measurement, continuous measurement, differential

measurement.

3) Zero point calibration, 2-point calibration and basic

calibration.

4) Metric and imperial units of measurement.

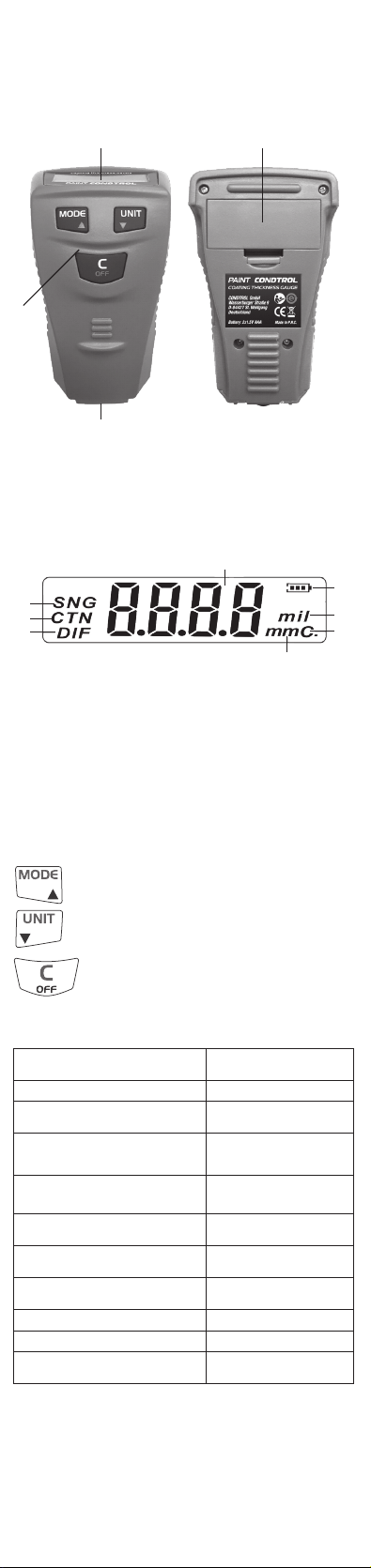

1 – LCD screen

2 – Keyboard

3 – Battery cover

4 – Probe

Display

1 – Indication of single measurement

2 – Indication of continuous measurement

3 – Indication of differential measurement

4 – Result of measurement

5 – Indication of battery charge level

6 – Imperial unit of measurement - mil

(1 mil = 0,0254 mm / 1/1000 inch)

7 – Metric unit of measurement (1 mm=39.4 mil)

8 – Indication of calibration mode

Functions of buttons

Select operation mode/increase value in

calibration mode

Select unit of measurement/decrease the value

in calibration mode

Switch on/switch off/zero point calibration

TECHNICAL SPECIFICATIONS

Measuring range 0…1.80 mm/0…71.0 mil

Minimal unit displayed 0.01 mm/1 mil

Accuracy ±0.03 mm

Minimal diameter of metal

substrate

50 mm

Minimal thickness of metal

substrate

0.5 mm

Power supply 2*1.5V AAA

Operating temperature 0…40 °C

Storage temperature -10…+50 °C

Operating relative humidity 10…95% RH

Dimensions 112*69*25 mm

Weight 0,065 kg

PACKAGE

Coating thickness gauge - 1 pc.

Metal plate – 1 pc.

Film reference samples – 6 pcs.

Batteries (ААА) – 2 pcs.

User manual – 1 pc.

DE

RU

PAINT

INSERT/REPLACE BATTERIES

Remove the battery cover. Install the batteries observing

correct polarity. Put the battery cover back. Use alkaline

batteries only, both batteries must be of the same brand

with the same charge level. Charge level is shown on display.

Replace batteries when you see symbol on the display.

SWITCH ON/SWITCH OFF

Short press button to switch on the device. It is

ready for operation as soon as you hear a single sound signal.

Press and hold button for 2 seconds , to switch off

the device.

CALIBRATION

The device should be calibrated before use to ensure precise

measurement.

This coating thickness gauge is able to perform calibration in

3 ways:

1) Basic calibration

This calibration should be arranged before first use of the

device or in case it hasn’t been used for a long time. It is also

recommended to arrange this calibration if metal surface has

been changed.

Prepare metal plate included in the package and remove

protective film from its surface. Prepare film reference

samples included in the package as well - 0,05 mm, 0,1 mm,

0,25 mm, 0,5 mm, 1,0 mm и 2 m.

Press and hold buttons and

simultaneously until you hear a single sound signal. Display

will show value “0.00”, letter «С» will appear in the bottom

right corner, indicating calibration mode.

Bring the probe down onto metal plate without any coating.

Value «0.00» will appear on the display and the device will

emit double sound signal. 0.00 calibration is finished.

Remove the device from the metal plate. Value «0,05» will

appear on the display. Take «0,05» film reference sample and

put it on the metal plate.

Bring the probe down onto «0,05» film. Double sound signal

will indicate that the second point of calibration has been

passed. Thus, go through further calibration points using films

of different thickness included in the package. As soon as

2mm calibration is finished, «OVER» will appear on the display

and the device will turn off automatically. Basic calibration is

finished.

When basic calibration of the device is completed it can be

used for measurement of coating thickness applied on the

same metal as the calibration metal plate.

2) Zero point calibration

Switch on the device. Bring the probe down onto metal plate

without any coating and short press button .

Value «0.00» will appear on the display. Zero point calibration

is finished.

3) Two point calibration

Firstly perform zero point calibration.

Take «1.00» film reference sample and put it on the metal

plane. Bring the probe down onto a «1.00» film. Get the value

«1.00» on the display. If necessary adjust the value to «1.00»

by short press button and .

Remove the device from the film. Calibration is finished.

MEASUREMENT OF COATING THICKNESS

Switch on the device. Short press button to select

operation mode – single measurement, continuous

measurement, differential measurement.

Short press button to select the unit of measurement

– mm or mil.

Bring the probe down onto the surface. Coating thickness

measurement result will appear on the display. If the device is

removed from the measured surface, the measurement result

will remain on the display.

In single measurement the first measurement result is fixed on

the display after double sound signal.

Continuous measurement is used for ongoing measurement

without detaching the probe from the surface. In this mode

sound signal is not emitted, measurement results are displayed

dynamically until the device is removed from the surface.

In differential measurement mode the device displays the

difference between the reference measurement value and

current one.

If device is switched on being installed on metal surface, «ERR»

will appear on the display and the device will automatically

switch off indicating incorrect use of the device.

RECOMMENDATIONS

Factors affecting the accuracy of measurement and their

description:

1) The probe must be kept strictly perpendicular to the coating

of the measurement surface to ensure accurate measurement.

2) Make sure that pressure exerted on the probe must be equal

and steady.

3) The device cannot measure thickness of coating if thickness

of metal surface is less than 0.5mm.

4) The device is sensitive to abrupt change of metal surface

shape on which measurements are made. If measurements

are made at the edges or in the corners of the metal surface,

measurement results may be unreliable.

5) Curvature of measured surface affects the measurement

accuracy. The larger the radius of curvature, the more accurate

the measurement results.

6) Roughness of both metal surface and coating affects the

measurement accuracy. This effect rises with the increase

of roughness and may lead to system and occasional errors.

Therefore it is necessary to make several measurements

in the same point to avoid these errors. If metal surface is

rough, firstly zero point calibration at several points with

same roughness and without coating should be carried out. If

necessary, remove the coating with a solvent, etc.

7) It is recommended to clean the surface of foreign

substances (dust, grease, corrosion products), because they

can affect measurement results. The coating itself should

remain unchanged.

CARE AND MAINTENANCE

Attention! This device is a precision instrument and

requires careful handling. Maintenance of the following

recommendations will extend the life of the device:

- Protect the device from bumps, falling and intense vibration;

do not allow moisture, dust and foreign objects get inside the

device.

- If liquids get inside the device, first remove the batteries,

then contact a service center.

- Do not store and use the device in increased humidity

conditions.

- Do not store the product in rooms where temperature is

below -10°С. After storage in low temperature conditions

and subsequent transfer to a warm room, the device heats

up, causing moisture condense inside the device and damage

microcircuits.

- Do not expose the device to direct sunlight and protect it

from prolonged exposure to sunlight and high temperature.

- Clean the device with a soft cloth slightly made damp with a

mild soap solution. Do not use cleaning solvents or abrasives.

Failure to observe the following rules may lead to electrolyte

leakage from the batteries and damage the device:

- Remove the batteries from the device if you don’t use it for

a long time.

- Do not use batteries of different types, with different charge

level.

- Do not leave discharged batteries in the device.

UTILIZATION

Expired tools, accessories and package should be passed

for waste recycle. Please send the product to the following

address for proper recycle:

CONDTROL GmbH

Wasserburger Strasse 9

84427 Sankt Wolfgang

Germany

Do not throw the product in municipal waste!

According to European directive 2002/96/ЕC expired

measuring tools and their components must be collected

separately and submitted to environmentally friendly recycle

of wastes.

WARRANTY

All CONDTROL GmbH products go through post-production

control and are governed by the following warranty terms. The

buyer’s right to claim about defects and general provisions of

the current legislation do not expire.

1) CONDTROL GmbH agrees to eliminate all defects in the

product, discovered while warranty period, that represent the

defect in material or workmanship in full volume and at its own

expense.

2) The warranty period is 24 months and starts from the date

of purchase by the end customer (see the original supporting

document).

3) The warranty doesn’t cover defects resulting from wear

and tear or improper use, malfunction of the product caused

by failure to observe the instructions of this user manual,

untimely maintenance and service and insufficient care, the

use of non-original accessories and spare parts. Modifications

in design of the product relieve the seller from responsibility

for warranty works. The warranty does not cover cosmetic

damage, that doesn’t hinder normal operation of the product.

4) CONDTROL GmbH reserves the right to decide on

replacement or repair of the device.

5) Other claims not mentioned above, are not covered by the

warranty.

6) After holding warranty works by CONDTROL GmbH

warranty period is not renewed or extended.

1

2

3

4

1

2

3

5

6

8

4

7

7) CONDTROL GmbH is not liable for loss of profit or

inconvenience associated with a defect of the device, rental

cost of alternative equipment for the period of repair.

This warranty applies to German law except provision of the

United Nations Convention on contracts for the international

sale of goods (CISG).

In warranty case please return the product to retail seller or

send it with description of defect to the following address:

CONDTROL GmbH

Wasserburger Strasse 9

84427 Sankt Wolfgang

Germany

PAINT

Bedienungsanleitung

Schichtdickenmessgerät

DE

Herzlichen Glückwunsch zum Kauf Ihres CONDTROL PAINT.

Bitte lesen Sie die Sicherheitshinweise sorgfältig, bevor Sie

das Gerät das erste Mal verwenden.

SICHERHEITSHINWEISE

Vorsicht! Die Bedienungsanleitung ist Bestandteil des

Gerätes. Vor Gebrauch des Gerätes lesen Sie die beiliegende

Bedienungsanleitung sorgfältig durch. Bei Weitergabe des

Geräts an einen anderen Nutzer, muss die Anleitung diesem

übergeben werden.

- Das Gerät darf nur zweckgemäß verwendet werden.

- Halten Sie Kinder und Dritte von Lasergeräten fern.

- Die Reparatur und Wartung darf nur durch qualifiziertes

Fachpersonal erfolgen, das originale Ersatzkomponenten

einsetzt.

- Verwenden Sie das Gerät nicht in der Nähe von brennbaren

Stoffen, da im Gerät Funken entstehen können.

- Benutzen Sie das Gerät nicht in der Nähe von brennbaren

oder leicht entflammbaren Materialien.

- Im Fall einer Explosion der Batterien besteht das Risiko von

Verletzungen durch Trümmer und Chemikalien. Löschen Sie

die Stellen sofort mit Wasser. Bei Kontakt der Flüssigkeit mit

Augen, reinigen Sie diese sofort mindestens zehn Minuten

lang mit sauberem Wasser und suchen Sie anschließend einen

Arzt auf.

BESTIMMUNGSGEMÄSSER GEBRAUCH

Das Schichtdickenmessgerät PAINT CONDTROL ist für schnelle,

genaue und zerstörungsfreie Messungen der Dichte von nicht

– magnetischen Metalloberflächen (Farbe, Folie) im Bereich

0 bis 1,80 mm geeignet. Das Gerät findet Anwendung in

vielen Bereichen, wie Metallherstellung und -Bearbeitung, in

chemischer Industrie, bei der Qualitätskontrolle der Waren

und Autos u.s.w.

Funktionen:

1) Schichtdickenmessung an Metalloberflächen.

2) Modus der Einzel-, Dauer – und Differenzmessungen.

3) Nullpunkt-, Zweipunkt- und Grundkalibrierung.

4) Metrische und britische Maßangaben.

1 – LCD- Anzeige

2 – Tastatur

3 – Batteriefachdeckel

4 – Sensor

1

2

3

4

Display

1 – Einzelmessung

2 – Dauermessung

3 – Differenzmessung

4 – Messergebnis

5 – Batteriestandsanzeige -

6 – britische Maßeinheit - mil

(1 mil = 0,0254mm / 1/1000 inch)

7 – metrische Maßeinheit (1mm=39.4mil)

8 – Anzeige des Kalibriermodus

Funktionen von Tasten

Auswahl Messungmodus /Wertsteigerung im

Kalibrierungsmodus

Maßeinheitauswahl/Wertminderung im

Kalibrierungsmodus

Einschaltung/Abschaltung/Nullpunktkalibrierung

TECHNISCHE SPEZIFIKATIONEN

Messbereich 0…1.80 mm/0…71.0 mil

Messeinheit 0.01 mm/1 mil

Genauigkeit ±0.03 mm

Minimaler

Oberflächendurchmesser

50 mm

Minimale Oberflächendichte 0.5 mm

Batterien 2*1.5V AAA

Betriebstemperatur 0…40 °C

Lagertemperatur -10…+50 °C

Relative Luftfeuchtigkeit bei

Betrieb

10…95% RH

Abmessungen 112*69*25mm

Gewicht 0,065kg

LIEFERUMFANG

Schichtdickenmessgerät - 1 St.

Metallplatte – 1 St.

Dünnschichtreferenzprobe (Folie) – 6 St.

Batterien (ААА) – 2 St.

Betriebsanleitung – 1 St.

BATTERIE EINSETZEN/AUSWECHSELN

Öffnen Sie das Batteriefach. Setzen Sie Batterien ein. Achten

Sie dabei auf die richtige Polung. Setzen Sie nur Batterien

desselben Herstellers und der gleichen Spannung ein. Ersetzen

Sie die Batterien, wenn das Symbol permanent auf dem

Display blinkt.

Ein-/Abschaltung des Gerätes

Drücken Sie kurz die Taste , um das Gerät

einzuschalten. Das Gerät ist betriebsbereit sobald Sie das

Einzelsignal hören.

Halten Sie die Taste 2 Sekunden gedrückt, um das

Gerät abzuschalten.

KALIBRIERUNG

Für eine genaue Messung soll das Gerät vor dem Betrieb

kalibriert werden. Das Schichtdickenmessgerät kann auf drei

Arten kalibriert werden:

1) Grundkalibrierung

Dieser Kalibrierungsmodus wird vor dem ersten Gebrauch

des Gerätes durchgeführt oder falls das Gerät lange Zeit nicht

benutzt wurde. Die Kalibrierung wird auch empfohlen falls die

Metalloberfläche geändert wurde.

Stellen Sie die Metallplatte aus dem Lieferumfang bereit,

entfernen Sie Schutzfolie und Folien mit Dicke von 0,05mm,

0,1mm, 0,25mm, 0,5mm, 1,0mm und 2mm.

Halten Sie die Tasten und gedrückt bis

Sie ein kurzes Tonsignal hören. Auf dem Display erscheint der

Wert 0.00 und in der rechten unteren Ecke wird der Buchstabe

«С» eingeblendet, das bedeutet, dass der Kalibrierungsmodus

aktiviert ist.

1

2

3

5

6

8

4

7