BAL0813-0007-EN

www.conductix.com translated document page 3 of 108

5Transport, Packaging and Storage ...........................................................................................................................................38

5.1 Safety ........................................................................................................................................................................38

5.2 Transport ...................................................................................................................................................................39

5.3 Packaging..................................................................................................................................................................39

5.4 Storage of packaged parts ........................................................................................................................................40

6Installation.................................................................................................................................................................................41

6.1 Safety ........................................................................................................................................................................41

6.2 Provide additional protection against contact at the conductor rail end. ...................................................................44

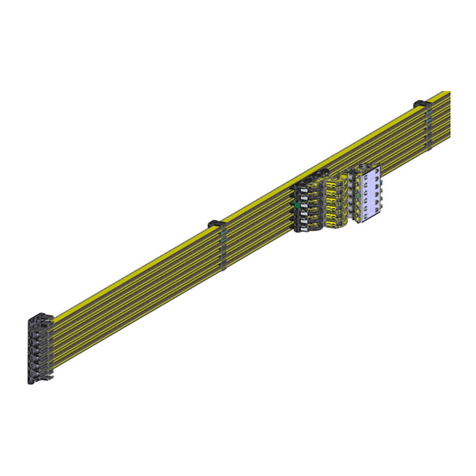

6.3 System arrangement .................................................................................................................................................45

6.4 Installation of mechanical components......................................................................................................................46

6.4.1 Required tools ...........................................................................................................................................................46

6.4.2 Trim conductor rail.....................................................................................................................................................46

6.4.3 Install conductor rail system ......................................................................................................................................49

6.4.3.1 50

6.4.3.2 Mount hanger clamps ................................................................................................................................................50

6.4.3.3 Mount conductor rail ..................................................................................................................................................54

6.4.3.4 Connect rails..............................................................................................................................................................57

6.4.3.5 Line feed....................................................................................................................................................................60

6.4.3.6 Mount anchor clamp ..................................................................................................................................................63

6.4.3.7 Mount heating wire (optional) ....................................................................................................................................65

6.4.3.8 Mount expansion unit ................................................................................................................................................67

6.4.3.9 Mount air gap.............................................................................................................................................................69

6.4.3.10 Mount end caps .........................................................................................................................................................72

6.4.3.11 Mount pickup guide ...................................................................................................................................................75

6.4.4 Mount current collector ..............................................................................................................................................78

6.4.4.1 Current collector insertion from the side....................................................................................................................82

6.4.4.2 Typical mounting errors.............................................................................................................................................82

6.5 Electrical installation ..................................................................................................................................................83

6.5.1 Conductor Rail...........................................................................................................................................................83

6.5.2 Current Collector .......................................................................................................................................................83

6.6 Further Documents....................................................................................................................................................83

7Commissioning .........................................................................................................................................................................84

7.1 Safety ........................................................................................................................................................................84

7.2 Testing and initial commissioning..............................................................................................................................86

7.2.1 Test list ......................................................................................................................................................................86

7.2.2 Initial commissioning of the conductor rail system ....................................................................................................88

8Operation ..................................................................................................................................................................................89