BAL0815-0002g-US

www.conductix.us translated document page 3 of 128

3.2.3 Tolerances.................................................................................................................................................................19

3.3 Unsuitable environmental conditions.........................................................................................................................20

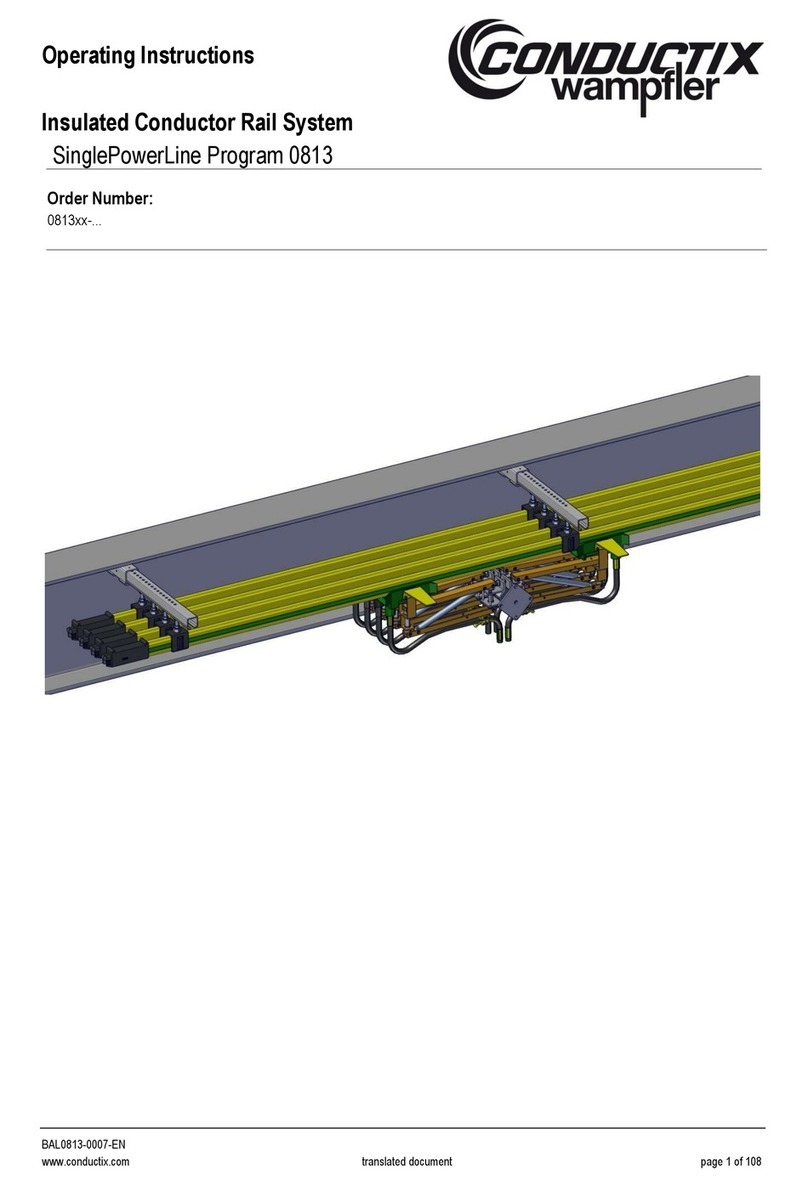

4Product Description and Functional Principles .........................................................................................................................21

4.1 Brief description.........................................................................................................................................................21

4.2 Interfaces...................................................................................................................................................................24

4.3 Description of the components..................................................................................................................................25

4.4 Accessories ...............................................................................................................................................................30

4.4.1 Tools and materials ...................................................................................................................................................30

5Transport, Packaging and Storage ...........................................................................................................................................31

5.1 Safety ........................................................................................................................................................................31

5.2 Transport ...................................................................................................................................................................32

5.3 Packaging..................................................................................................................................................................33

5.4 Storage of packaged parts ........................................................................................................................................33

6Installation.................................................................................................................................................................................34

6.1 Safety ........................................................................................................................................................................34

6.2 Provide additional protection against accidental contact at the conductor rail end ...................................................37

6.3 Procedure..................................................................................................................................................................38

6.3.1 Required tools ...........................................................................................................................................................38

6.3.2 Customizing components ..........................................................................................................................................38

6.3.2.1 Trimming conductor rails ...........................................................................................................................................39

6.3.2.2 Making a notch for the PEplus rail ...............................................................................................................................40

6.3.2.3 Making a bend in the conductor rail...........................................................................................................................42

6.3.3 Installing the conductor rail system ...........................................................................................................................45

6.3.3.1 Mounting the hanger clamps .....................................................................................................................................46

6.3.3.2 Mounting the fixed point ............................................................................................................................................49

6.3.3.3 Mounting conductor rail and connectors (on straight routes) ....................................................................................52

6.3.3.4 Mounting conductor rail and connector (in closed slip ring applications) ..................................................................56

6.3.3.5 Expansion unit and expansion module......................................................................................................................61

6.3.3.5.1 Determine the number of expansion modules........................................................................................................ 64

6.3.3.5.2 Mounting the expansion module with a setting aid................................................................................................. 68

6.3.3.5.3 Mounting the expansion module without a setting aid............................................................................................ 76

6.3.3.6 Mounting air gap insulation section ...........................................................................................................................78