Table of Contents

1. INTRODUCTION ..........................................................................................................................................................................................1

Conventional Hubs ............................................................................................................................................................................1

PreSet Hub Assemblies.....................................................................................................................................................................1

PreSet Plus Hub Assemblies.............................................................................................................................................................1

2. INSPECTION................................................................................................................................................................................................2

HAZARD ALERT MESSAGES .....................................................................................................................................................................2

WHEEL END INSPECTION GENERAL GUIDELINES..................................................................................................................................2

Driver Pre-Trip Visual Inspection.......................................................................................................................................................2

In Route Inspections..........................................................................................................................................................................2

Service Interval..................................................................................................................................................................................3

Lubrication Analysis ..........................................................................................................................................................................3

3. IDENTIFICATION .........................................................................................................................................................................................4

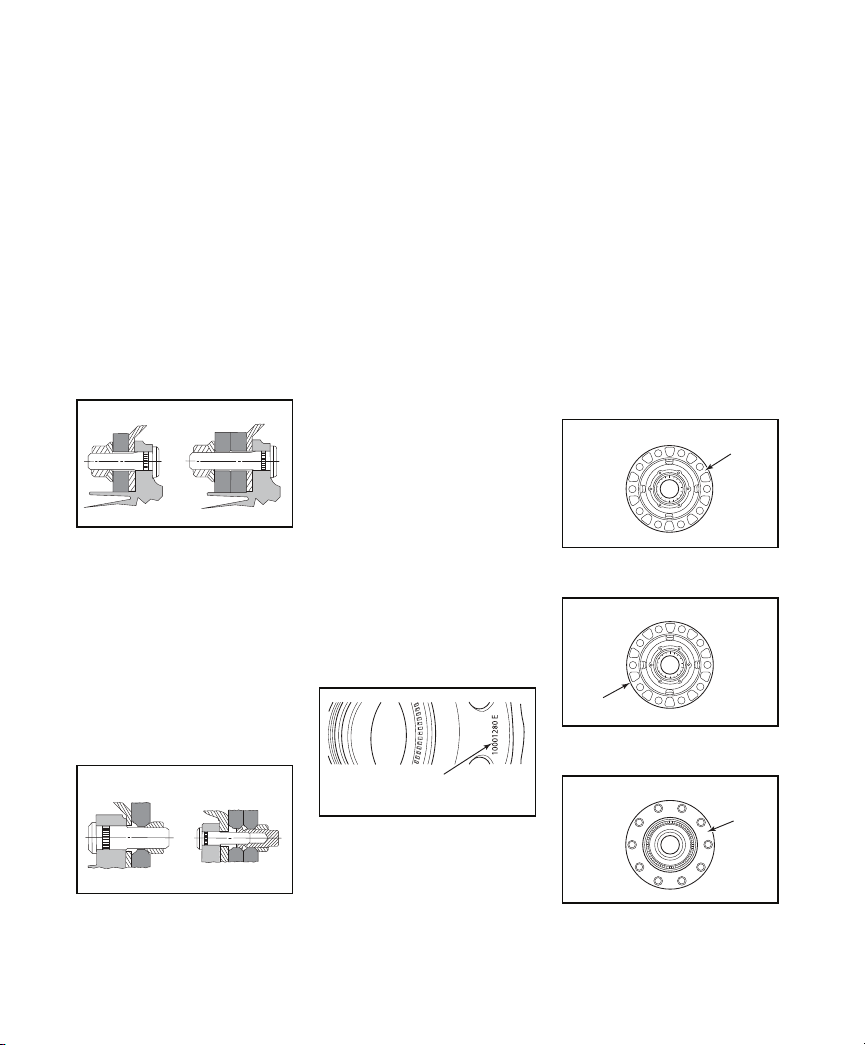

WHEEL MOUNTING SYSTEMS ..................................................................................................................................................................4

Hub Pilot Wheel Mounting .................................................................................................................................................................4

Ball Seat Wheel Mounting System.....................................................................................................................................................4

IDENTIFYING CONMET HUB ASSEMBLIES...............................................................................................................................................4

Vehicle Identication Number (VIN) ..................................................................................................................................................4

Casting Number ................................................................................................................................................................................4

Machining Number............................................................................................................................................................................4

Final Hub Assembly Number.............................................................................................................................................................5

Julian Date.........................................................................................................................................................................................5

Conventional Wheel Hubs ...........................................................................................................................................................5

PreSet Wheel Hubs......................................................................................................................................................................5

PreSet Plus Wheel Hubs ..............................................................................................................................................................5

4. CONVENTIONAL WHEEL HUBS ................................................................................................................................................................6

HUB REMOVAL AND DISASSEMBLY ........................................................................................................................................................6

COMPONENT INSPECTION AND REPLACEMENT HAZARD ALERT MESSAGES....................................................................................7

CLEAN AND DRY COMPONENTS .............................................................................................................................................................7

Worn or Damaged Components .......................................................................................................................................................7

Hub and Component Cleaning .........................................................................................................................................................7

INSPECTING BEARING CUPS AND CONES..............................................................................................................................................8

REMOVING CUPS IN ALUMINUM HUBS...................................................................................................................................................8

REMOVING CUPS IN IRON HUBS .............................................................................................................................................................8

INSTALLING A NEW CUP IN ALUMINUM HUBS .......................................................................................................................................8

INSTALLING A NEW CUP IN IRON HUBS .................................................................................................................................................8

WHEEL STUDS ...........................................................................................................................................................................................9

STUD REMOVAL.........................................................................................................................................................................................9

STUD REPLACEMENT................................................................................................................................................................................9

HUB, DRUM AND WHEEL INSPECTION....................................................................................................................................................9

ABS TONE RING INSPECTION (AS APPLICABLE) ....................................................................................................................................9

REMOVAL AND INSTALLATION OF MACHINED ABS TONE RING ........................................................................................................10

REMOVAL AND INSTALLATION OF STAMPED STEEL ABS TONE RING ...............................................................................................10

REMOVAL AND INSTALLATION OF BOLT ON ABS TONE RINGS..........................................................................................................10

REASSEMBLY...........................................................................................................................................................................................11

CONVENTIONAL WHEEL HUBS ASSEMBLY...........................................................................................................................................11

REINSTALLATION ....................................................................................................................................................................................12

INSTALLING CONMET CONVENTIONAL WHEEL HUBS.........................................................................................................................12

Spindle Preparation.........................................................................................................................................................................12

Conventional Hub Installation..........................................................................................................................................................12

Manual Bearing Adjustment Procedure (reference TMC RP618) ...................................................................................................13

SERVICE PARTS .......................................................................................................................................................................................14

5. PRESET WHEEL HUBS ............................................................................................................................................................................17

HUB REMOVAL AND DISASSEMBLY ......................................................................................................................................................17

COMPONENT INSPECTION AND REPLACEMENT HAZARD ALERT MESSAGES..................................................................................18

CLEAN AND DRY COMPONENTS ...........................................................................................................................................................19

Worn or Damaged Components .....................................................................................................................................................19

Hub and Component Cleaning .......................................................................................................................................................19

INSPECTING BEARING CUPS AND CONES AND BEARING SPACER ...................................................................................................19

REMOVING CUPS IN ALUMINUM HUBS.................................................................................................................................................19

REMOVING CUPS IN IRON HUBS ...........................................................................................................................................................20

INSTALLING A NEW CUP IN ALUMINUM HUBS .....................................................................................................................................20

INSTALLING A NEW CUP IN IRON HUBS ...............................................................................................................................................20

WHEEL STUDS .........................................................................................................................................................................................20

STUD REMOVAL.......................................................................................................................................................................................20

STUD REPLACEMENT..............................................................................................................................................................................20

HUB, DRUM AND WHEEL INSPECTION..................................................................................................................................................21

ABS TONE RING INSPECTION (AS APPLICABLE) ..................................................................................................................................21

REMOVAL AND INSTALLATION OF ABS TONE RING ............................................................................................................................21

REMOVAL AND INSTALLATION OF STAMPED STEEL ABS TONE RING ...............................................................................................21

REMOVAL AND INSTALLATION OF BOLT ON ABS TONE RINGS (FOR DISC BRAKES).......................................................................22

REASSEMBLY...........................................................................................................................................................................................23

PRESET WHEEL HUBS.............................................................................................................................................................................23