Table of Contents

Part 1 Disclaimer of Liability and

Limitation of Warranty 1

Part 2 Introduction to the CNC1/CNC2

box 2

................................................................................................................................... 31 Front panel controls

................................................................................................................................... 42 Rear Panel Connections

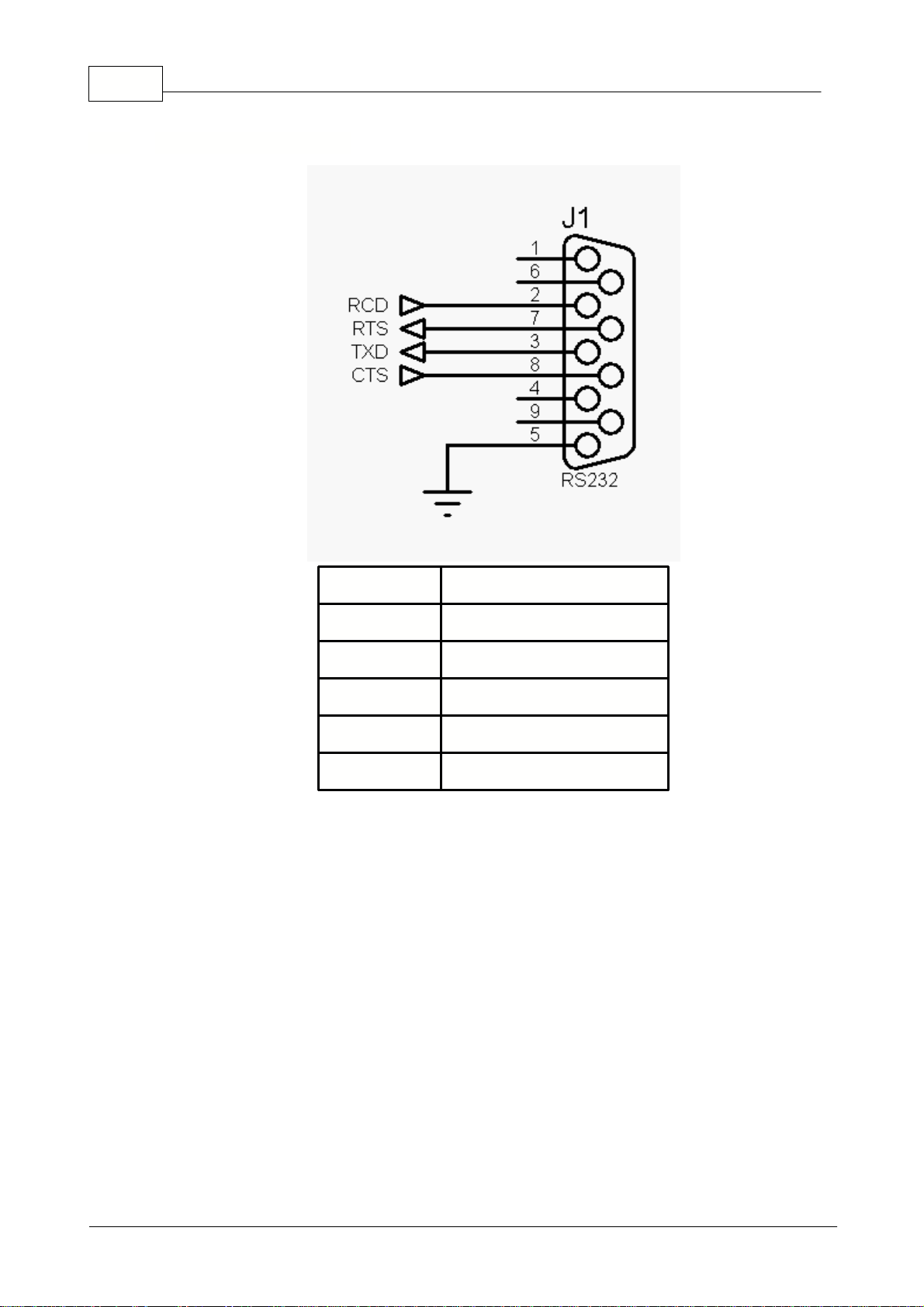

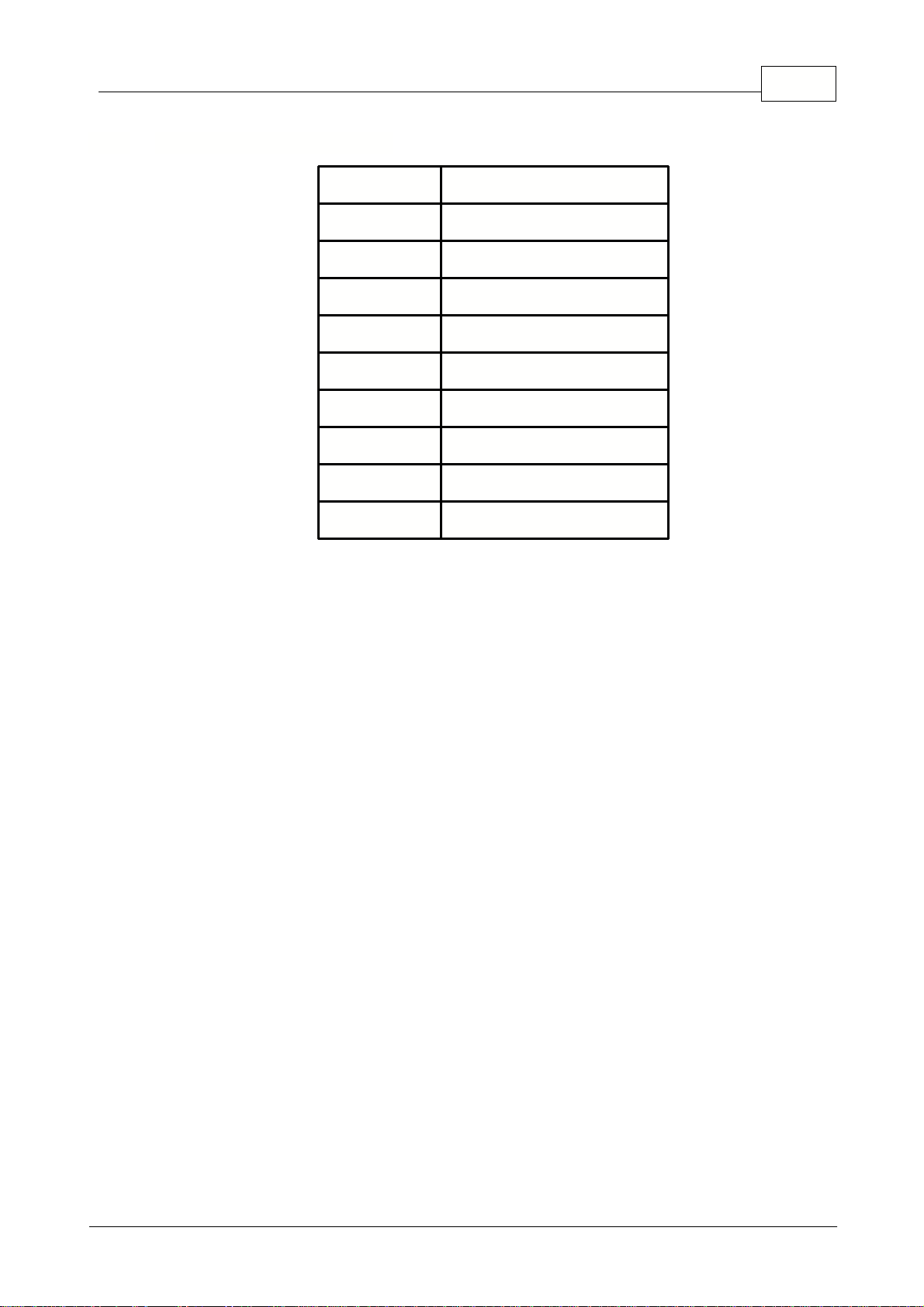

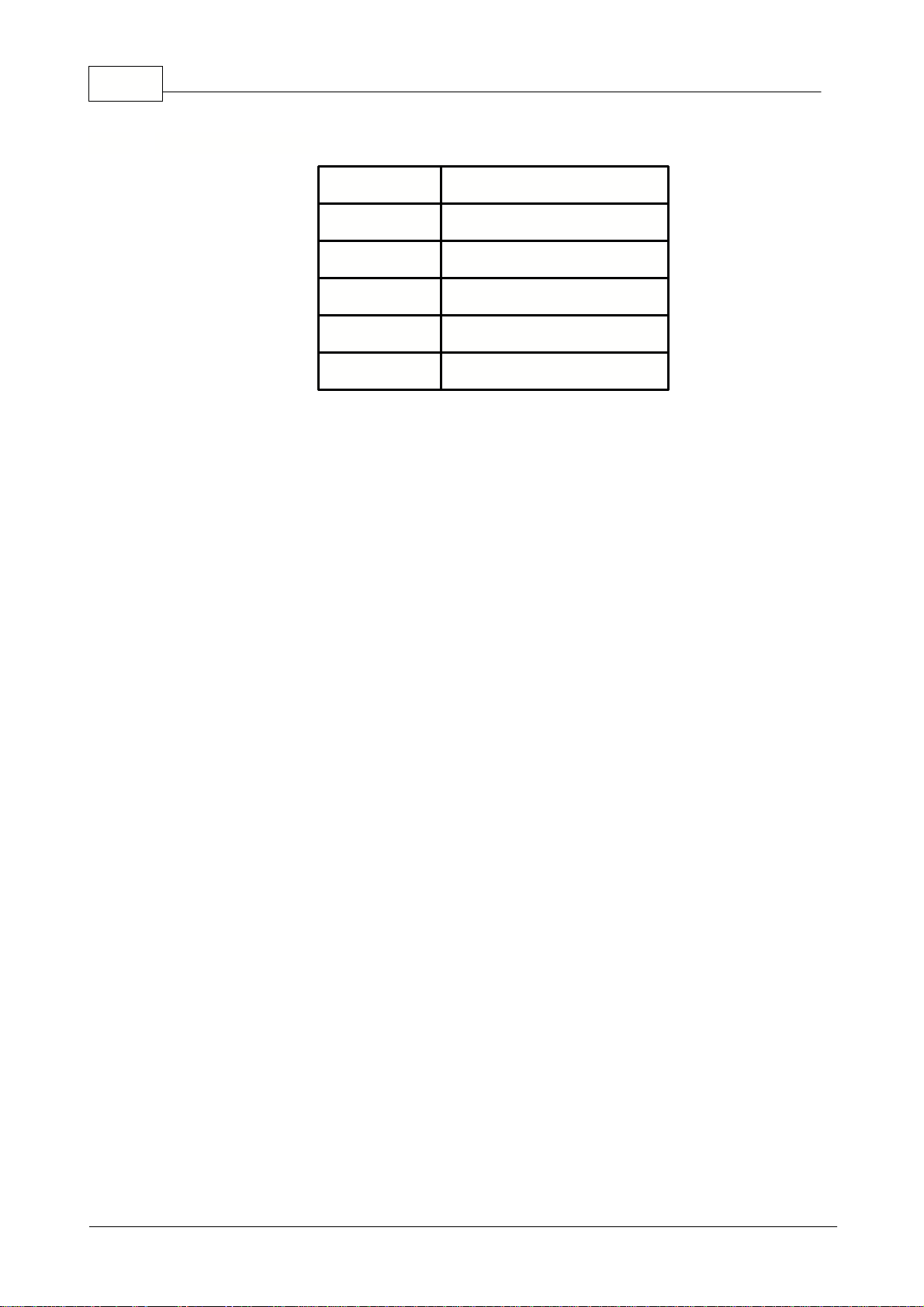

......................................................................................................................................................... 5RS232 Serial Interface

......................................................................................................................................................... 6Spindle Motor control plug

......................................................................................................................................................... 7Relay drives plug

......................................................................................................................................................... 8Stepper motor plug

......................................................................................................................................................... 9Feed-back/Encoder/Limit-switchplug

................................................................................................................................... 103 Spare and replacement plugs

Part 3 Manual Operation without a

Computer 11

Part 4 Appendices 12

................................................................................................................................... 121 Compatible Motors

................................................................................................................................... 132 G-Codes

......................................................................................................................................................... 14Additional G-Codes for Lathe Operations

......................................................................................................................................................... 15Additional G-Codes for Milling Operations

................................................................................................................................... 163 M-Codes

................................................................................................................................... 174 Command Set

................................................................................................................................... 195 Control Parameters

Index 24

IContents

I

Copyright©2005ConquerorDesignandEngineeringLtd.