Manual CCP800/CSP800 Emissions Tester

8

TIME DATE- used to adjust clock in

smokehead (restrictions may apply)

VTS FORM, used to enter garage details

INFO - displays a page of information

about the program and system.

RETURN to Main Menu - used to return

to the previous screen

Shut down Procedure

1. Exit the main menu using the EXIT icon.

2. Double click the SHUT DOWN icon from the PC

desktop.

3. After a short period the computer will shut

down. It is then safe to turn the power o.

MOT TEST PROCEDURE

The engine must be at normal operating

temperature before performing the test, either

apply the test immediately the vehicle is

presented or warm up thoroughly before testing.

.

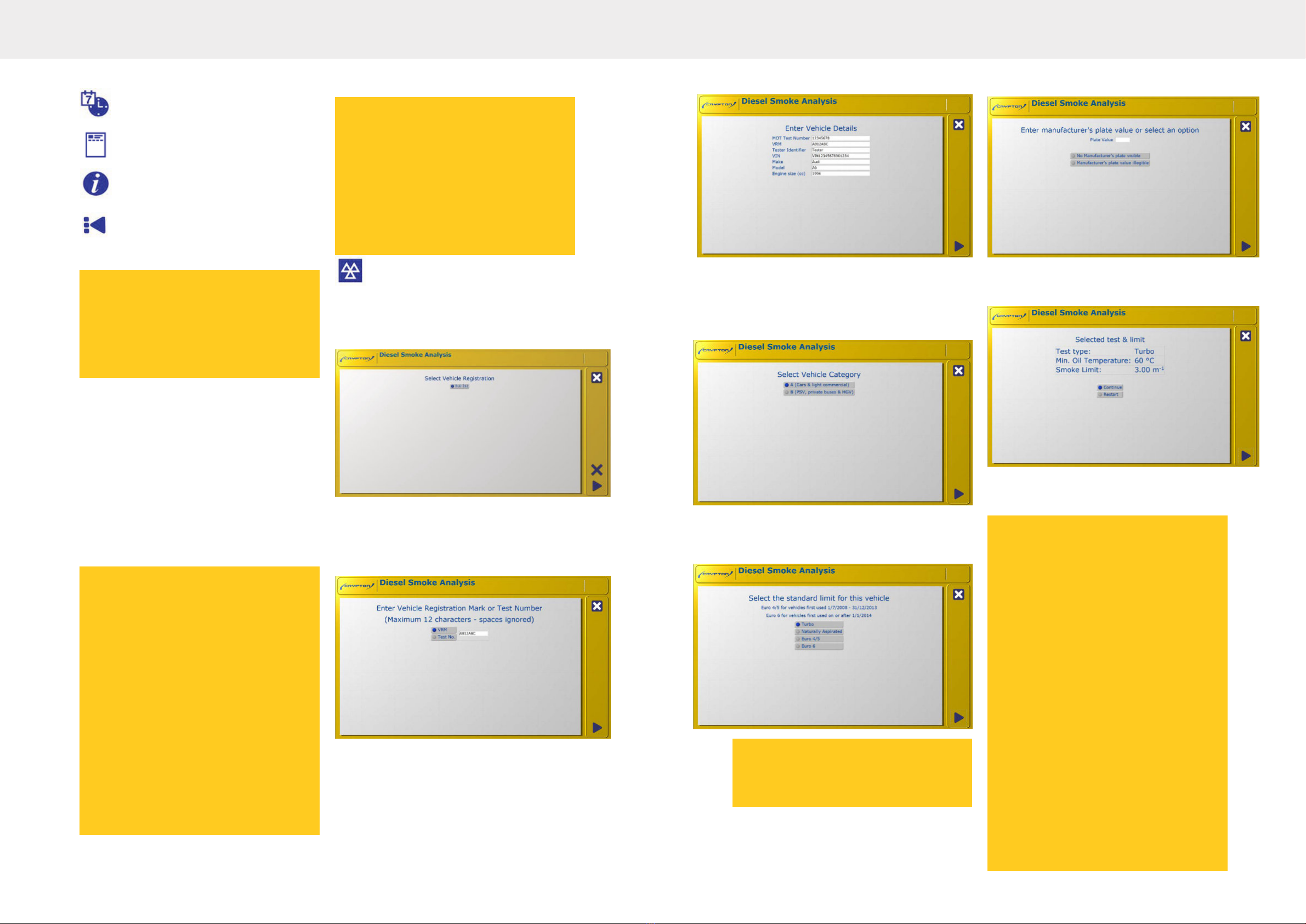

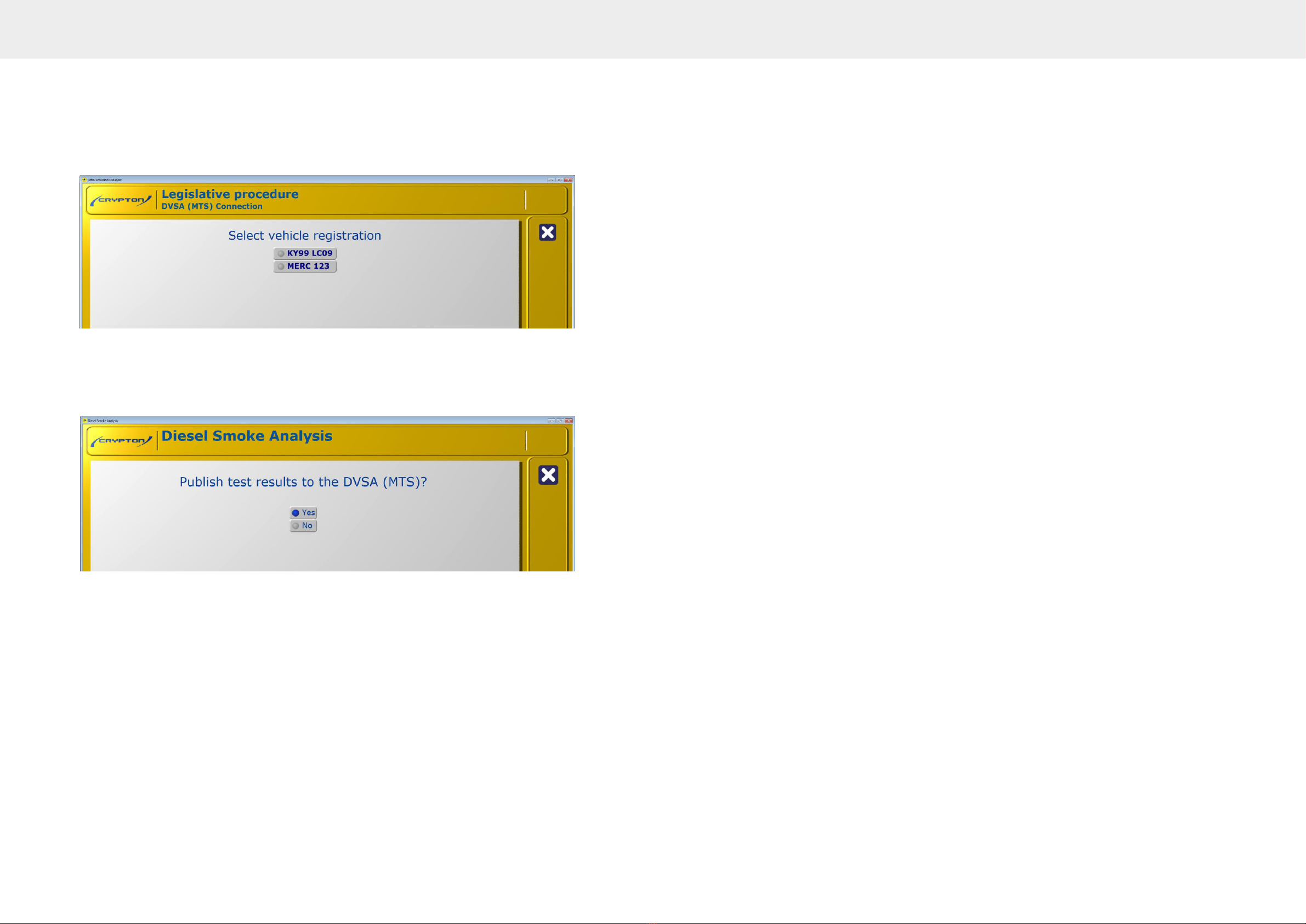

1. Select the icon to initiate the MOT test.

2. Type the Vehicle Registration Mark or Test

Number in the box using the keyboard.

Spaces between letters/numbers are not

important as they will be ignored.

3. If you do not have a connection to the DVSA

MTS on-line service, type the Vehicle Registration

Mark or Test Number in the box using the

keyboard. Spaces between letters/numbers are not

important as tey will be ignored.

4. Provided all is well the screen will display the

complete test selection to be used for

this MOT test. Check the details are correct and

click the PROCEED icon to continue.

Clicking the EXIT icon will ABORT the test back to

the main menu. Fields will be automatically

populated with vehicle information if the vehicle

was dened on the DVSA MTS on-line service.

IMPORTANT:

Always follow the correct shut-down

procedure before turning the power o.

This prevents the hard disk being lled

with unwanted les and causing

operational problems at a later date.

WARNING:

If carrying out tests in a workshop, the

area should be well ventilated.

Alternatively, outdoor testing is

permissible (see 'Outdoor Testing' in the

Hardware Operators Manual).

Ensure that the vehicle is parked on level

ground with handbrake applied and

gear lever in neutral or park position.

Turbocharged engines should be

allowed to idle for 10 to 15 seconds

before switching o to ensure

maximum turbocharger life.

It is recommended that prior to carrying

out the M.0.T. test, the engine speed

governor is checked as follows:

Fit the engine speed adapter (see

section 'Engine Speed Adapters' in the

Hardware Operators Manual). SLOWLY

raise the engine speed and check that

the engine manufacturer's maximum

speed cannot be exceeded.

DO NOT proceed further if the engine

speed exceeds the manufacturer's

gures.

Manual CCP800/CSP800 Emissions Tester

9

5. Select the vehicle category type then click on

the PROCEED icon to continue.

6. If Category A test for Cars and light commercial

is selected than a limits choice screen is displayed.

7. If Category B test for HGV/PSV is selected than

an RPC (Reduced Pollution Certicate) option is

enabled.

8. If Turbo is selected, the test limits will be

displayed.

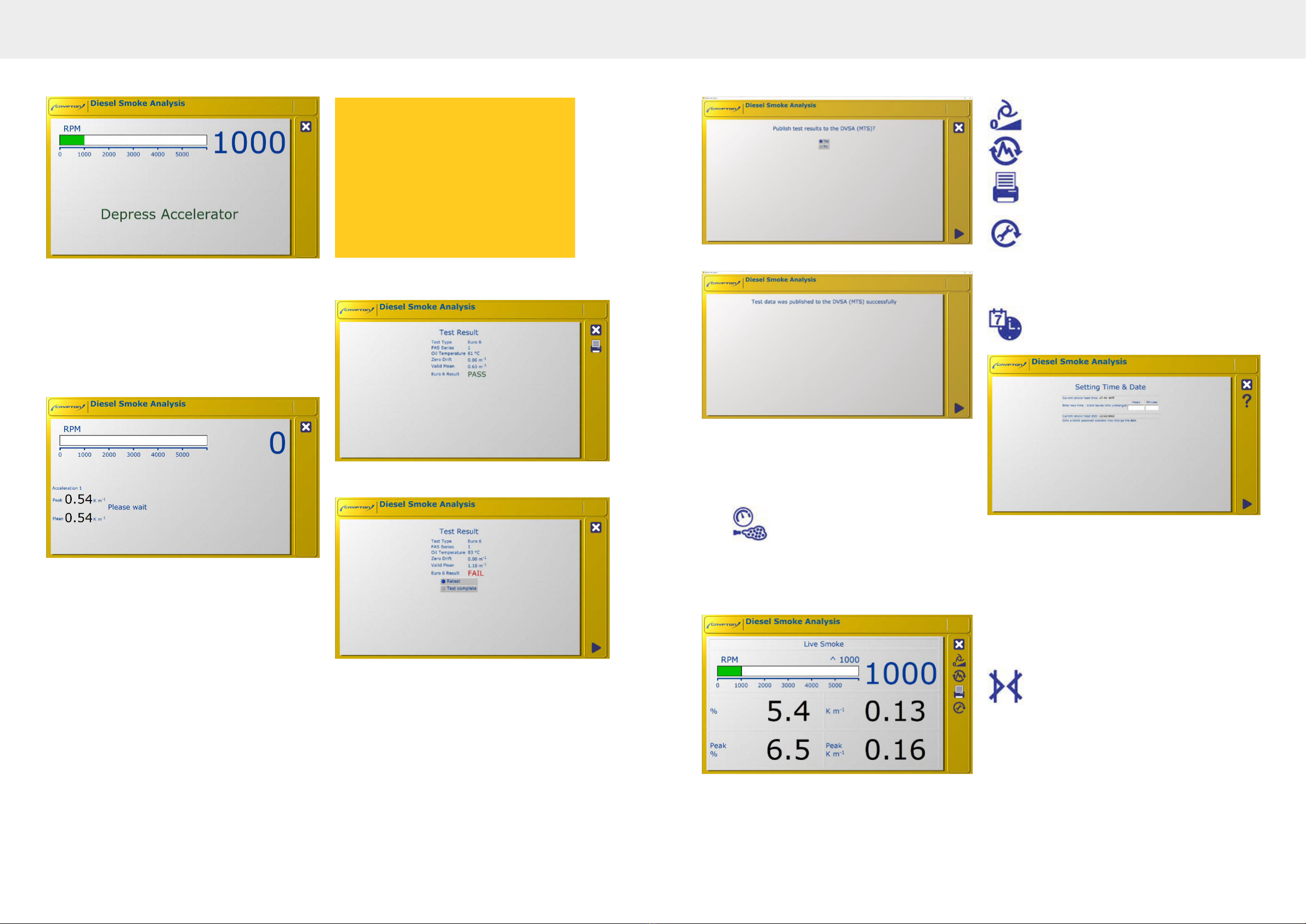

9. OIL TEMPERATURE - only applicable to classes

4 and 7.

NOTE:

RPC options are only available fr

Category B tests.

NOTE:

The oil temperature procedure will be

automatically bypassed if a temperature

probe is not tted.

WARNING:

Ensure the oil temperature probe is set

to the correct length before inserting

into the engine. Failure to do so may

result in serious damage to the

probe and/or engine.

NOTE:

If you have a Bluetooth VCI congured,

it will be an available option for reading

engineer temperature. Choose ‘EOBD

Interface’ and follow on-screen

instructions.

Not every vehicle supplied with a 16-pin

EOBD connector supports EOBD. This

applies to petrol and diesel vehicles.

Communication will not be possible for

vehicles which use unsupported

protocols.