CRS 202910 User manual

CRS Advanced Filter

System

202900

202910

Operation Guide

2 CRS Advanced Filter System

Document Number 995101

Version 2

P

C

2

L

U

t

w

Recycling

For recycling contact your local CRS Sales

Office

Safety Notices

WARNING

WARNINGS

WARNING notices must be read carefully

and understood. Improper use of this

product can cause harm or death to

personnel and damage to property!

CRS Advanced Filter System 3

Operation Manual

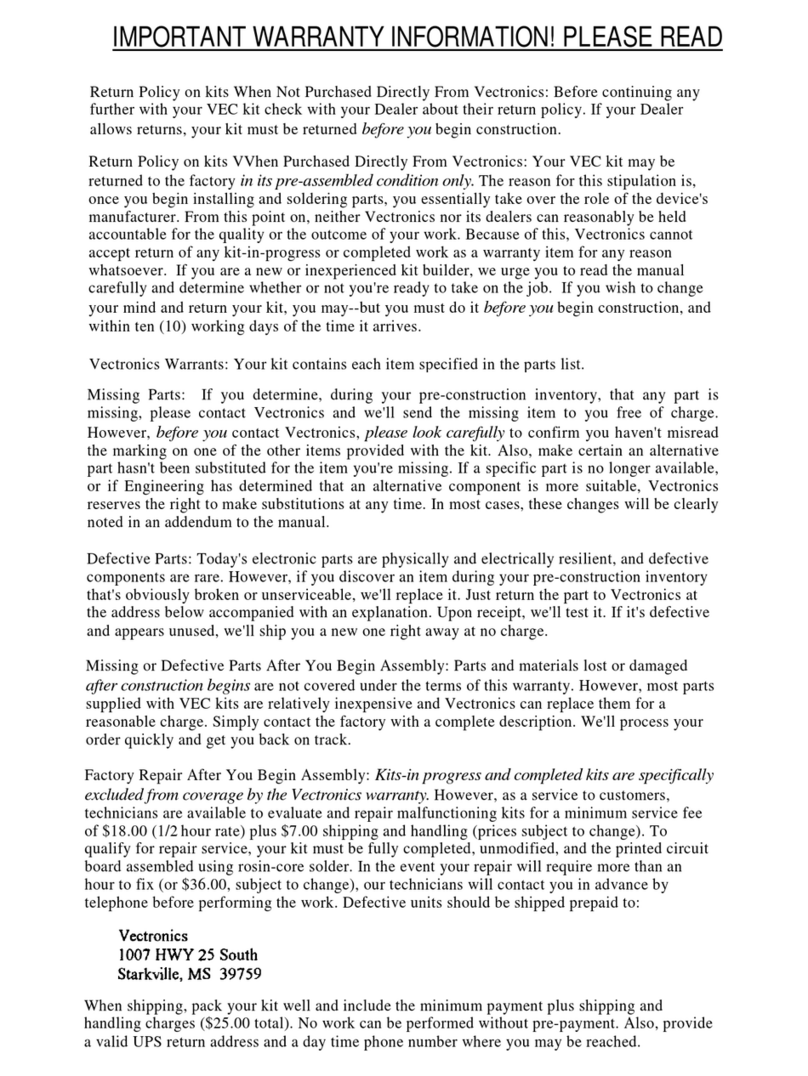

This operation manual applies to the following products:

• CRS Advanced Filter System,

part number 202900

• CRS Advanced Filter System, replacement cartridge

part number 202910

4 CRS Advanced Filter System

Filter Setup

Please read through this entire manual to familiarize yourself with the operation of the Advanced Gas

Filter System before beginning setup. Use the same degree of care as you would with any precision

instrument.

Remove the AFS Cartridge, Manifold and Mounting Brackets from the package.

Inspect the filter system. If there is any visible damage contact your supplier immediately.

CRS Advanced Filter System 5

Warnings

Remember to wear safety glasses.

Leak test all fittings when using hazardous or flammable gases.

Do not use above 14 bar (200psi).

Do not open filter cartridge, even after use!

Points on Manifold block are sharp.

Special precautions might be required when using hydrogen. Consult local

regulations and your company’s safety procedures.

The Advanced Filter System is intended to remove 50ppm or less of

oxygen, water, or hydrocarbons (C4 and above) from helium and other inert

gases, nitrogen or hydrogen at flow rates of 1L/minute or less.

Do not use to remove more than 50ppm of oxygen! Rapid heating of the

oxygen adsorbent will occur – and very high temperatures can result.

Limits: Temperature 15ºC to 35ºC

Pressure 0.75 to 14 bar

Gas Supply < 50ppm O2, H2O and Hydrocarbons

Flow Rate < 1L/min

6 CRS Advanced Filter System

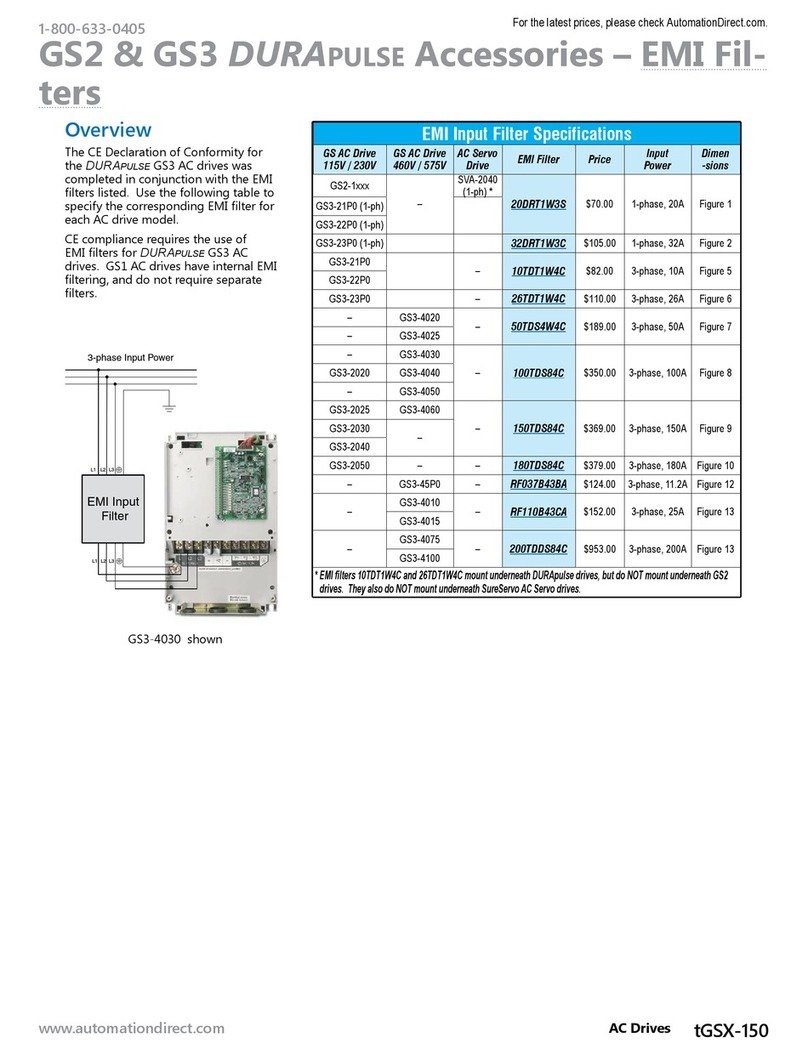

Connecting the Manifold

NOTE: Do NOT remove the black plastic covers from the check valves until manifold installation

is complete!

1. The manifold block must be connected to the gas lines. The compression fittings on the block fit

1/8” stainless tubing. If you need to connect the filter to lines of another diameter, adapters will

need to be installed first.

2. Select the bracket, bench-mount (L-shaped) or wall-mount (flat), which you intend to use. Use the

bracket first to mark the holes on the bench or wall where the manifold will be mounted.

The bench-mount bracket can also be attached without screws by using the supplied double sided

tape.

3. Drill the holes to mount the bracket, either to fit the anchors provided or to fit the screws without

anchors, depending on the requirements. In the case of the Bench Mount I configuration (see

pictures below) the bracket should be screwed into position at this point.

4. Insert the long hex-head screw into the back of the manifold if it is not already in position. Fasten

one of the brackets to the manifold, trapping the long screw.

5. Fasten the bracket to the bench or wall in the correct position.

6. Thread the nuts, back ferrules and front ferrules onto the tubing. Insert the tubing into the

manifold fittings, making sure that it reaches the bottom of the fitting.

7. Tighten the compression fittings. Compression fittings normally require about ¾ turn past the

finger-tight position for a good seal. Do not overtighten or the fittings may be damaged.

8. Remove the protective plastic cups from the manifold check valves. Be careful, the ends of the

check valves are sharp!

Bench Mount I

A gap of at least 25mm is

required behind the bracket

Inlet

Outlet

CRS Advanced Filter System 7

Optional Bench Mount I / II without Screws

Make sure to clean the area on benchthoroughly, before placing the bracketin place.

Note: Tapemounting is notintended forwall use

Wall Mount Bench Mount I

Bench Mount II

A gap of at least 25mm is

required behind the bracket

>25mm

Bench Mount I

with no screws

Bench Mount II

with no screws

A gap of at least 25mm is

required behind the bracket

>25mm

8 CRS Advanced Filter System

Mounting the Filter Cartridge

The cartridge is protected in shipping by two port plugs with O-ring seals. In addition, two

aluminum cups limit the exposure of adsorbent during assembly, until they are pierced as the

cartridge is mounted. Exposure to air of several minutes during filter installation or change will

not damage the adsorbent.

1. Remove the two port plugs. Save these plugs in case the cartridge is to be returned in an

exchange after the cartridge has been consumed.

2. Rest the alignment slot of the cartridge on the bottom support rod of the manifold, and

slide it forward until the two ports of the manifold slide into the sockets of the cartridge.

Be careful to point the check valve needles into the port holes so that they do not scratch

the back of the filter.

3. Push the cartridge forward, engage the clamping screw and tighten thoroughly.

4. Leak check the fittings.

If you are using hydrogen or hazardous gas, additional special procedures may be called

for. Consult your company’s safety procedures.

5. The filter cartridge is shipped full of helium, but the gas lines should still be purged with

a gas flow for at least several hours after the initial installation. Moisture levels

downstream of the instrument may continue to improve for several days.

CRS Advanced Filter System 9

Operation and Maintenance

The Advanced Filter System has two visual indicators, one for oxygen and one for moisture. When the

green indicator changes to gray, indicating oxygen contamination, or the blue indicator changes to light

brown, indicating water contamination, the filter cartridge should be changed.

To exchange the spent cartridge, first turn off the gas supply upstream of the filter. Shut down any

instruments downstream of the filter. The check valves in the manifold will interrupt the gas supply when

the cartridge is removed and protect the gas lines from the atmosphere.

Unscrew the clamping screw. This pushes the cartridge off the manifold spools. Only after the screw is

completely disengaged is it possible to remove the filter from the manifold.

Mount the replacement cartridge as instructed in the section “Setup”.

10 CRS Advanced Filter System

Troubleshooting

Condition Possible Cause Recommendation

Leak O-rings between cartridge

and manifold are not leak

tight.

Remove and check the manifold O-

rings for dirt or scratches. Inspect

the sealing surfaces on the cartridge

and manifold for scratches. Replace

if necessary.

Indicator changes

quickly.

Leak in gas line. Leak-check the overall system.

Contaminated Gas Verify that the source meets

specifications as listed under

“Limits” on page 5.

If the gas source is supplying other

filters as well, check the condition

of these filters. Otherwise check

specification and procedures for

verifying gas quality.

This manual suits for next models

1

Table of contents

Other CRS Water Filtration System manuals