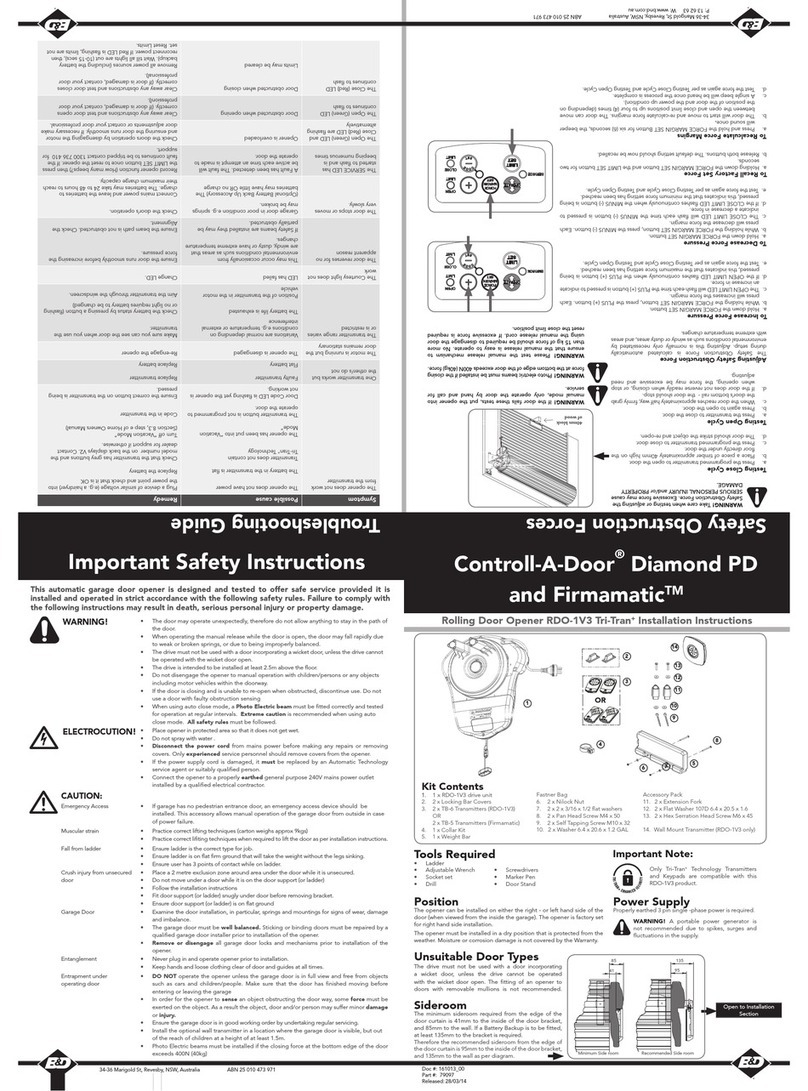

Thank you for choosing a Controll-A-Door® S automatic

garage door opener, designed and developed in Australia

by B&D Doors.

The technically advanced construction of this opener

ensures you enjoy the following benefits:

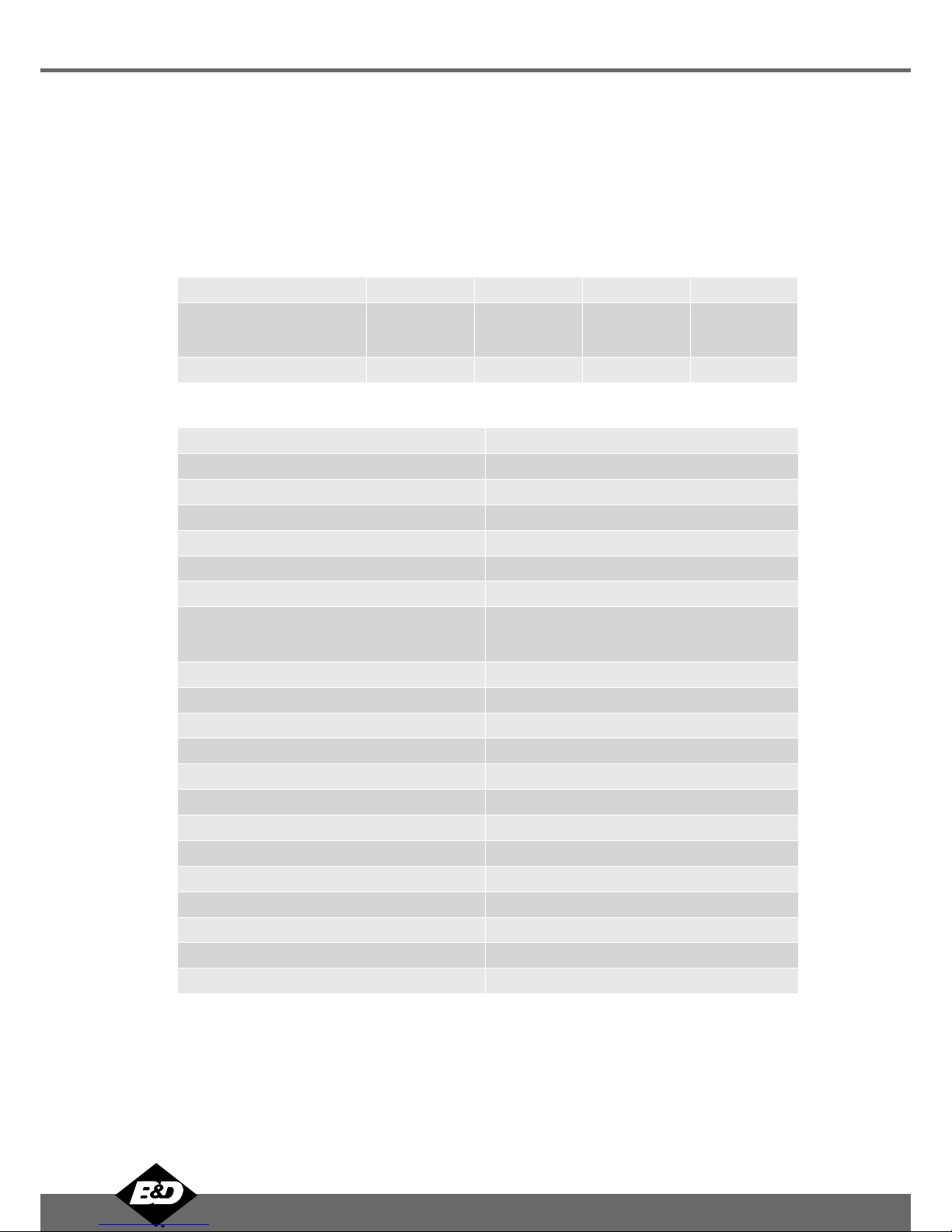

Warranty

Five (5) year/10,000 cycles full parts and labour warranty

on motor, electronics and mechanical components of

the opener when installed by an Approved B&D Dealer

(conditions such as annual garage door servicing apply).

Tri-Tran Frequency Hopping Technology

Every time a transmitter is used, it simultaneously sends a

signal over three different frequencies, reducing the chance

of interference from other radio frequency sources.

Code Hopping Technology

Every time a transmitter is used a new security code

is generated from over 4.29 billion possible code

combinations. This greatly enhances the security of the

system and makes “code grabbing” a thing of the past!

Multi-Channel Transmitter

Multi-channel transmitters allow you to operate other

devices such as an adjoining garage door or automated

gate from the same handy unit.

Warranty Expired Indicator

The opener will indicate that the number of cycles covered

by the warranty has been reached by flashing the courtesy

light 10 times after each operation. This flashing will

continue for 20 cycles unless it is reset by pressing the SET

button while the courtesy light is flashing.

S-ALPS (Semi Automatic Limits Positioning

System)

The S-ALPS system does away with manual adjustment of

the door’s limits position using mechanical parts, such as

cams and microswitches.

Safety Reversing System

The automatic safety reverse system significantly reduces

the risk of death or serious injury if trapped by a closing door.

The safety reverse force can be adjusted for environmental

conditions such as windy areas.

Courtesy Light

The courtesy light automatically switches on for

approximately three (3) minutes when operating the door.

This can also be programmed to turn on and off from a

transmitter.

Battery Back Up

Optional Battery Back Up or solar power is available.

Memory Retention

In case of a power failure the opener does not lose the

transmitter codes or limit settings.

Soft Start/Soft Stop

The opener eases into and out of each cycle making

for smoother and quieter operation, as well as reducing

wear and tear on the door and opener.

Manual Release

The manual release handle allows the door to be

operated by hand in the event of a power failure.

Self Locking

There is no need to manually lock your garage door, as

the opener ‘positively’ locks the door when closed.

Periodic Maintenance Indicator

The SERVICE LED will illuminate to indicate that

periodic maintenance is required. Contact your dealer/

installer for service.

Service Fault Indicator

Flashing LEDs on the control panel easily identify

operational problems or service requirements.

Dynamic Door Profiling

Changing door characteristics are automatically

compensated for and “learnt” with each operation of

the door.

External Aerial

An external aerial can be connected for sites where

radio reception is a problem.

Vacation Mode

A transmitter can be programmed to disable the

garage door opener radio receiver. This is ideal if the

door is to be left idle for prolonged periods.

Pet (Pedestrian) Mode

A transmitter can be programmed to open the door

partially to allow pets access to the garage. The door

opening height is adjustable via a handheld programmer.

Auxiliary Output

You can program a spare button on your transmitter to

operate this output, which can control items that use a

momentary close switching mechanism.

About Your B&D Opener

D Power Drive : Instruction Manual

© Copyright 2009 B&D Doors

5Controll-A-Door®S Instruction Manual