WARNING

1. CAUTION: Review all installation instructions, procedures, cautions and warnings contained

within this manual prior to installing and/or servicing this product. Maximum fire protection is

provided when installed in accordance with factory specifications with provided fuse link

systems.

2. Installation and testing to factory specifications shall be performed by factory authorized

personnel for proper operation in accordance with all of the latest National Fire Protection

Association (NFPA), Underwriters Laboratories (UL), National Electrical Code (NEC), local,

state, county, district and/or other applicable building and fire standards, guidelines,

regulations and codes including, but not limited to, all appendices and amendments and the

requirements of the local Authority Having Jurisdiction (AHJ).

3. Installation to be performed by factory authorized door system technicians only.

4. Clear fire door opening and prohibit all traffic through door opening during system testing!

INTRODUCTION

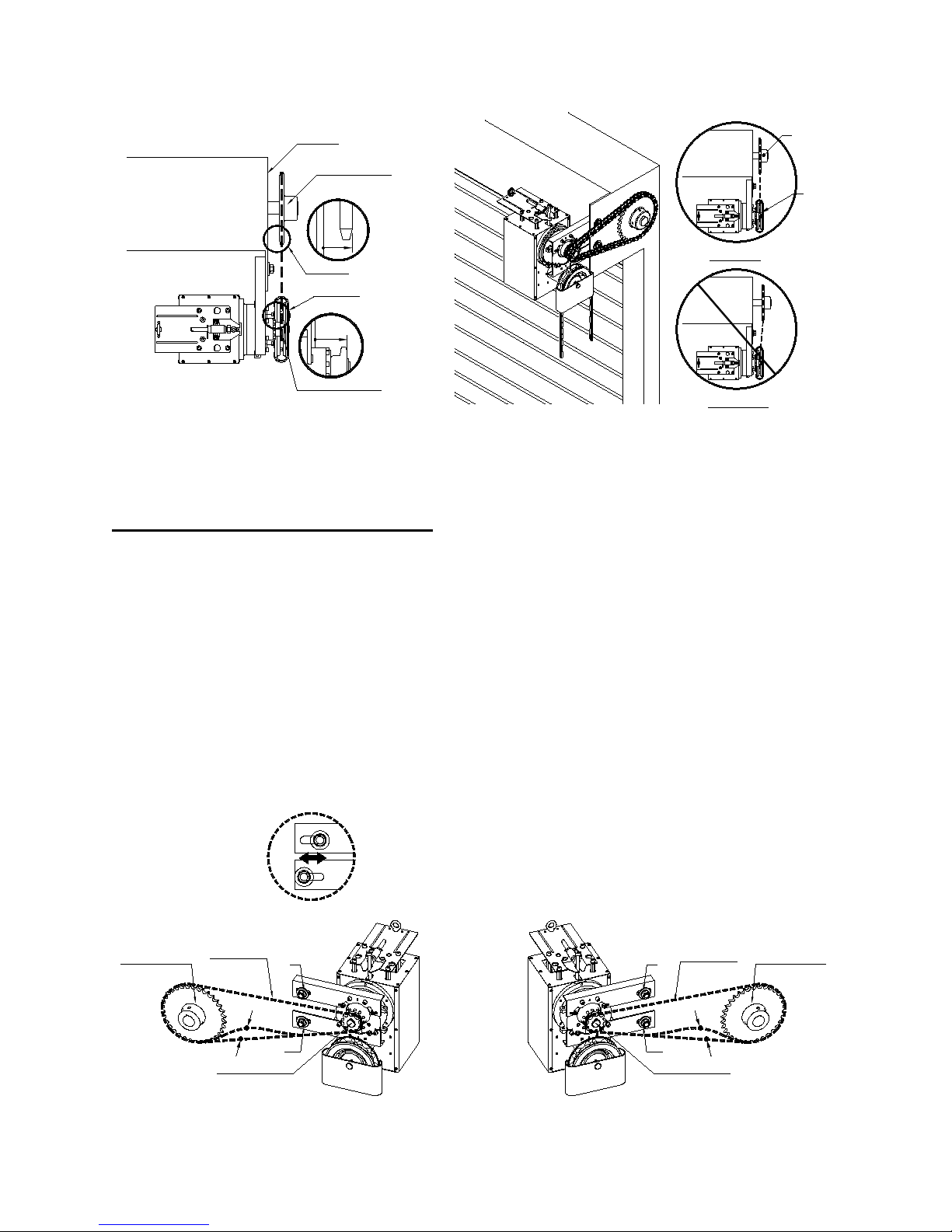

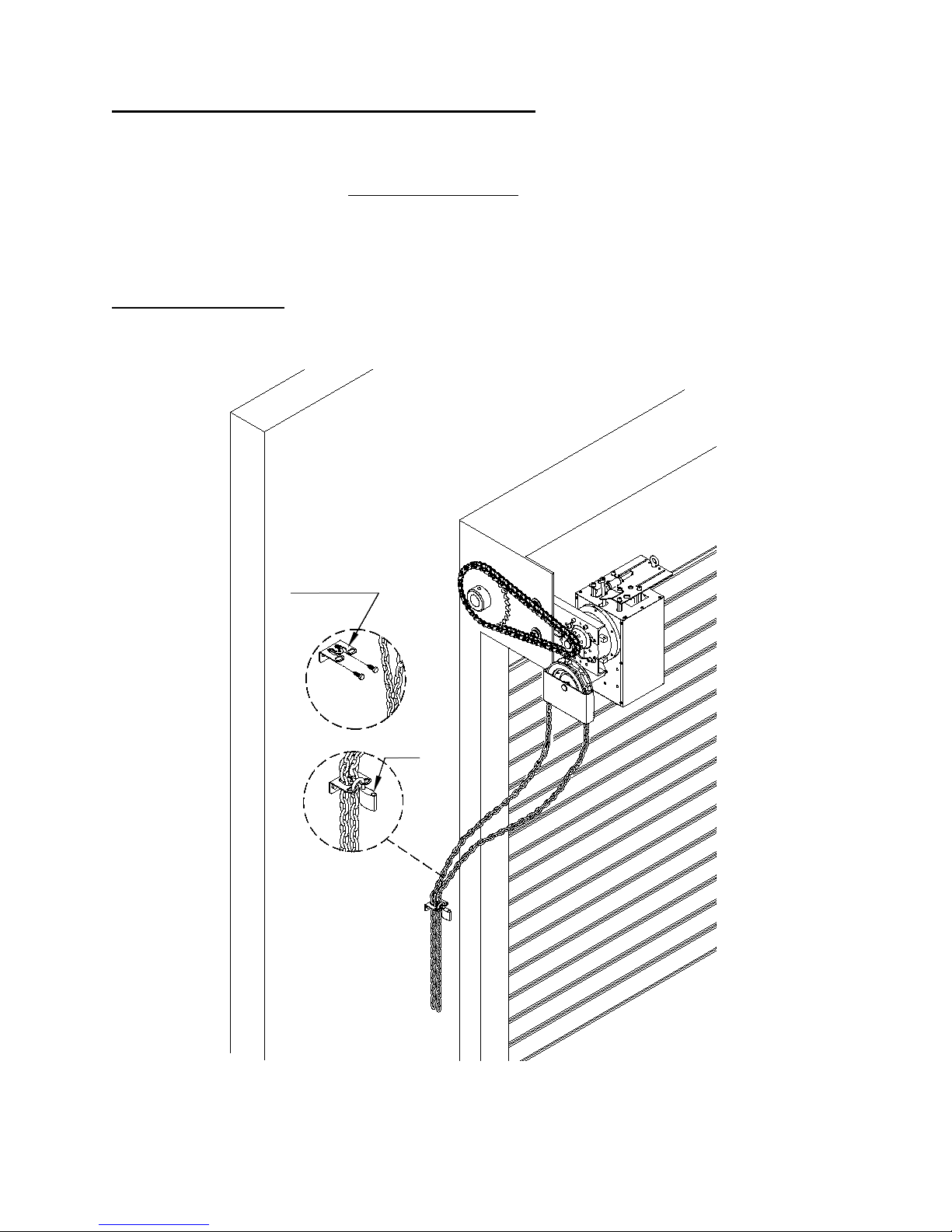

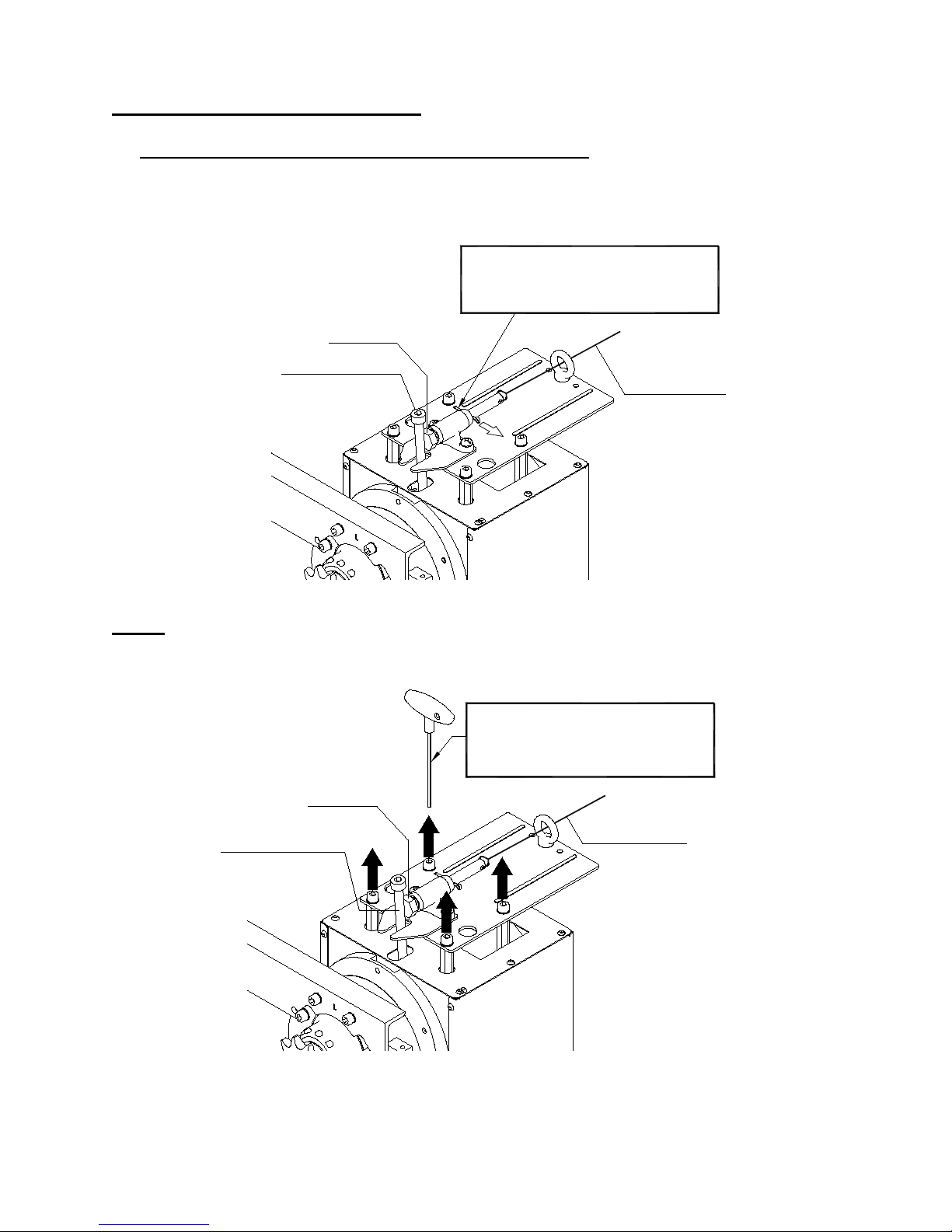

The closing system is designed to be used in conjunction with a temperature activated fusible

link arrangement. It is designed for use on rolling fire doors and counter fire doors. Optionally,

the unit is designed to accept a bolt-on, fail-safe floor level reset or automatic reset release device

for connection to local detectors or a central alarm system.