Rev. 12/8/2017 Page 5

Cool Machines Philosophy:

Never build, sell, or provide a service that is not good for our customer. Placing every

customer first by exceeding expectations with high performance machines, will assure an atmosphere

for achieving our highest potential.

This manual represents information regarding the latest and greatest machine technology used

in all-fiber, all-application machine technology. (Any duplication or use of this technology may be in

violation of Cool Machines Inc. rights.)

Cool Machines Inc. provides a solution offering the highest production and lowest power

requirements. We provide compact designs with the highest quality materials; offering the highest

durability, highest corrosion resistance, easiest maintenance, and simplest troubleshooting of any

machine in its class.

Theory of Operation:

The #1500 series machine provides a proprietary ‘scalping auger’ technology, with extreme

portability and low power requirements. As different fibers are loaded into the hopper, the proprietary

‘scalping/shredder’ augers located at bottom of hopper provide a live platform for breaking and

conditioning fibers. This feature provides a positive feeding, non-bridging method of metering fibers;

offering important advantages.

First: the ‘scalping’ action of augers provides a positive feed of fibers to shredder area while

the helix configuration of the 4-blade shredder provides highly conditioned fibers for application. (A

positive feeding system will meter the fiber accurately to airlock, no-matter what angle machine is

positioned on the job site.)

Second: the low profile position of augers in relation to higher hopper sides, and moderate

speed of auger assembly reduces possibility of operator injury, while greatly extending bearing and

chain life.

Easily accessed slide-gate (located adjacent to blower filter), has an ‘adjustment pin’ for

controlling & locking-in fiber feed rate. This feature allows for quick adjustment to desired settings. As

fiber is metered thru slide-gate area, the 4-blade scalping shredder provides aggressive break-up and

blending of fibers.

Fully expanded and conditioned fiber blend enters the high production airlock (10” dia. x 14”

long airlock) and is discharged into the high pressure air stream & hose provided by a single or

optional double blower system.

Economical single blower (optional double blower), system with variable rpm blowers,

provides adequate air for most applications up to 150ft. A 5 kw generator (7.5kw, 2-blower model), or

larger can provide adequate power for both the machine.

Efficient modular component design of maintenance access areas, drive system, blower

module and control panel; offer a simple, fast method to repair your machine. Job-site down-time is

minimized.

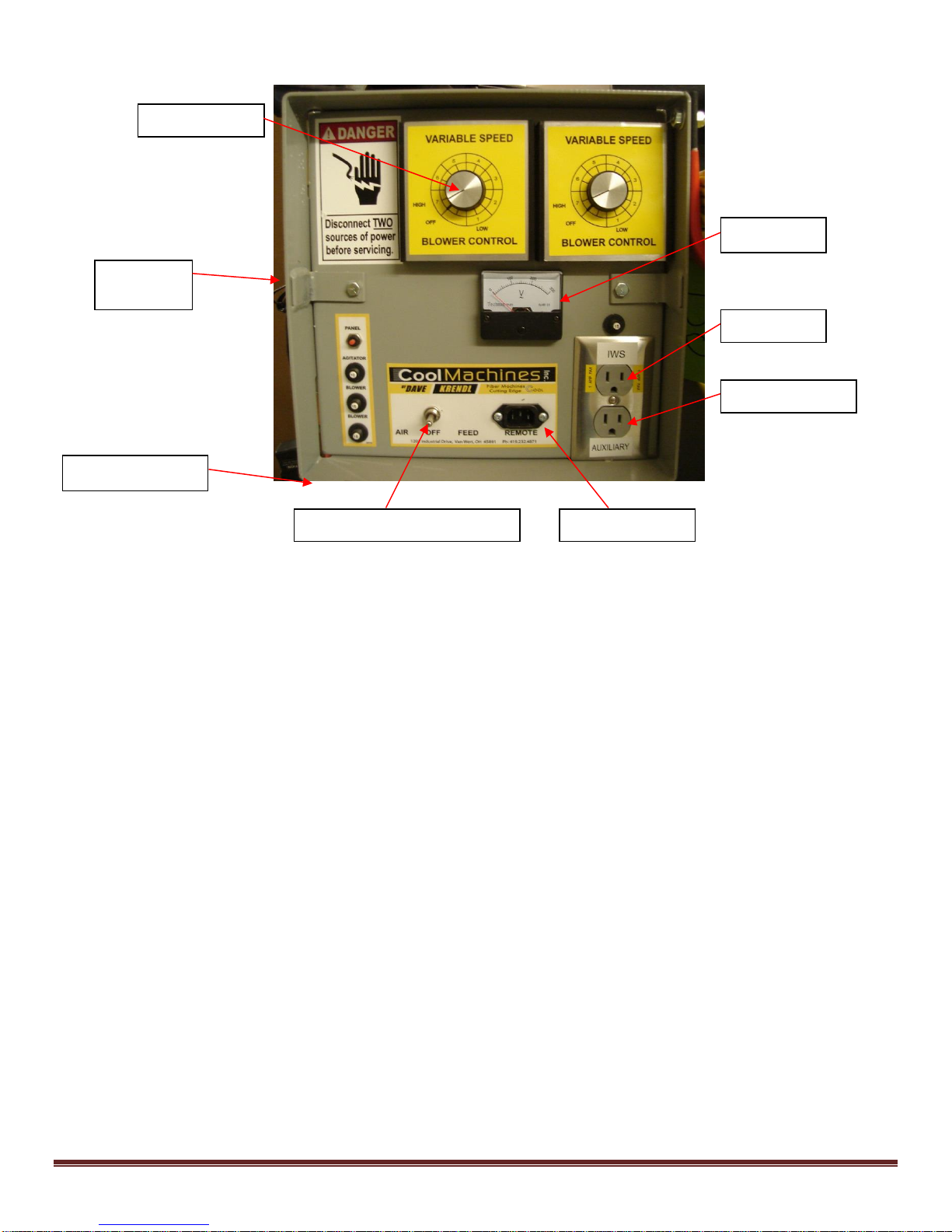

Electrical control panel is designed with simple, easy to access & by-pass components, which

provide the operator with an instant method to troubleshoot machine’s electrical system. Control

functions are simple and easy to understand. Manual thermal overloads provide a component that is

easily re-set, reliable, and most importantly - safe.

Inherent versatility of this machine’s design provides the core element for your future upgrade

to retro-sidewall and dense packing applications. This machine is one of the basic building blocks that

allow you to transition your business without costly equipment decisions.