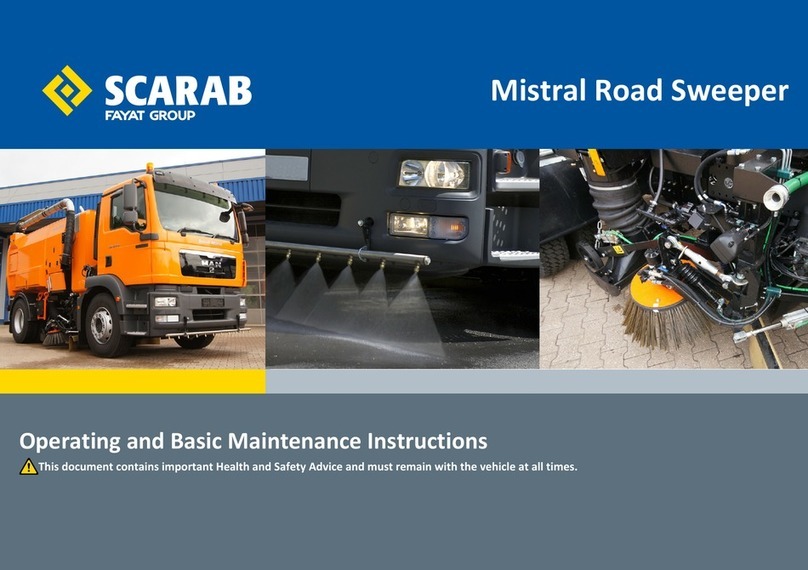

Scarab M65T Operating Instructions

Part No. SCAZ043468 1.6.01 10 E&OE

Health and Safety Advice

In the interests of your Health and Safety, it is important that the following points are followed all the time.

The universal safety symbol along with red text is used throughout this manual and when encountered the related information must be adhered to.

Refers to important information.

Identifies cautionary information and specific procedures when required.

Refers to visual examination to confirm the condition or status of a specific item.

Remember, failure to comply could result in serious injury.

• Only trained operatives should be allowed to drive or work on this machine.

• Before driving this machine ensure that all relevant machine checks have been

carried out and that all equipment is stowed.

• Do not overload the hopper.

• Do not drive the machine with the hopper in the raised position even if the hopper

is empty.

• Never work under a raised cab, hopper or rear door without the appropriate safety

prop in the correct position.

• Before operating the hopper or rear door controls, ensure that there is sufficient

clearance and that it is safe to do so. Ensure that all personnel are clear of the rear

door.

• Before working on the machine.

Position the machine on firm, level ground, apply the handbrake, stop both engines

and remove the ignition key.

• Always wear the appropriate personnel protective equipment (PPE) when

operating or working on the machine.

• Before starting engines ensure that all controls are switched off and the machine is

in neutral.

• Keep long hair, loose clothing and hands clear of moving parts.

• High pressure water can be hazardous, always wear suitable face protection when

operating the high pressure water pump and when using the high pressure water

lance.

Do not direct the water jet at other persons.

Beware of electrical installations on public buildings and lampposts etc.

Use extreme caution when using in public places.

• The drivers seat should be correctly adjusted while the vehicle is stationary to give

the driver a good posture whilst the vehicle is being driven.

• The mirrors should be adjusted while the vehicle is stationary to give the driver a

good all round of the sides and the sweeping equipment.

• When operating the machine in any mode always be aware of objects and people

in the immediate vicinity, especially at the rear of the machine when reversing.

• Whatever the situation, remember that the rules of traffic and road safety must

always be observed and obeyed.

• While operating this machine the safety and well being of other people around the

machine are the sole responsibility of the driver/operator.

• Never ride in/on any part of the machine other than in the drivers cab.