SECTION ONE

Introduction

This manual was prepared as aguide for the person in-

volved in the maintenance or overhaul of DuroFlow@ 45

Series Blowers utilizing splined rotor shafts and timing

gears. There are two versions, one of which uses spur

gears and the other, helical gears.

The helical gear version is the latest in the evolution of

DuroFlow blower technology. It differs from its prede-

cessor, the spur gear version, only in the gear tooth

configuration and the addition of aBelleville spring

behind one timing gear. On the helical gear blower,

rotor timing is accomplished by varying the position of

alock nut moving one timing gear axially against the

pressure of the Belleville spring washer. This slight

longitudinal movement of the drive gear in relation to

the idler gear changes the angular relationship be-

tween the two rotors.

In the spur gear version, rotor timing is accomplished

by selective assembly. Aparticular set of gears is

matched to aparticular set of rotors in order to achieve

the proper angular relationship between the two

rotors.

This manual is concerned primarily with the helical

gear version, which is currently in production.

Section Eight covers the differences in teardown and

reassembly procedure for the spur gear version.

Each of the four sizes of 45 Series blowers has four

configurations designated by the position of the drive

shaft as viewed from the drive end. The most common

configuration, designated vertical-top (VT), has the

drive rotor above the idler rotor and the airbox inlet

and discharge ducts are at the sides. In the vertical-

bottom (VB) configuration, the drive rotor is mounted

below the idler rotor. In the horizontal-left (H L)config-

uration, the drive rotor is to the left of the idler rotor

and the airbox inlet and discharge ducts are at the top

and bottom of the unit. In the horizontal-right (HR)

configuration, the drive rotor is mounted to the right

of the idler rotor.

The VT and HL configurations are identical except for

the position of the oil breather and the oil filler plug

and a change in the mounting plate in the HL. Like-

wise, the VB and the HR configurations correspond to

each other with the same differences as the VTand HL.

The VT-HL differs from the VB-HR in having adif-

ferent oil flinger on the drive end which is mounted on

the drive shaft in the VB-HR version rather than on

the idler shaft as in the VT-HL. Both oil flingers are

identical in the VT-HL version, whereas the drive end

flinger is more deeply dished than thegear end fiinger

in the VB-HR versions.

Since the VT version is the most common of the

various configurations, the illustrations and the tear-

down and reassembly procedures in this manual refer

to the VT configuration. The person involved in

overhauling one of the other versions of the blower

should keep in mind the differences noted in the

preceding paragraphs.

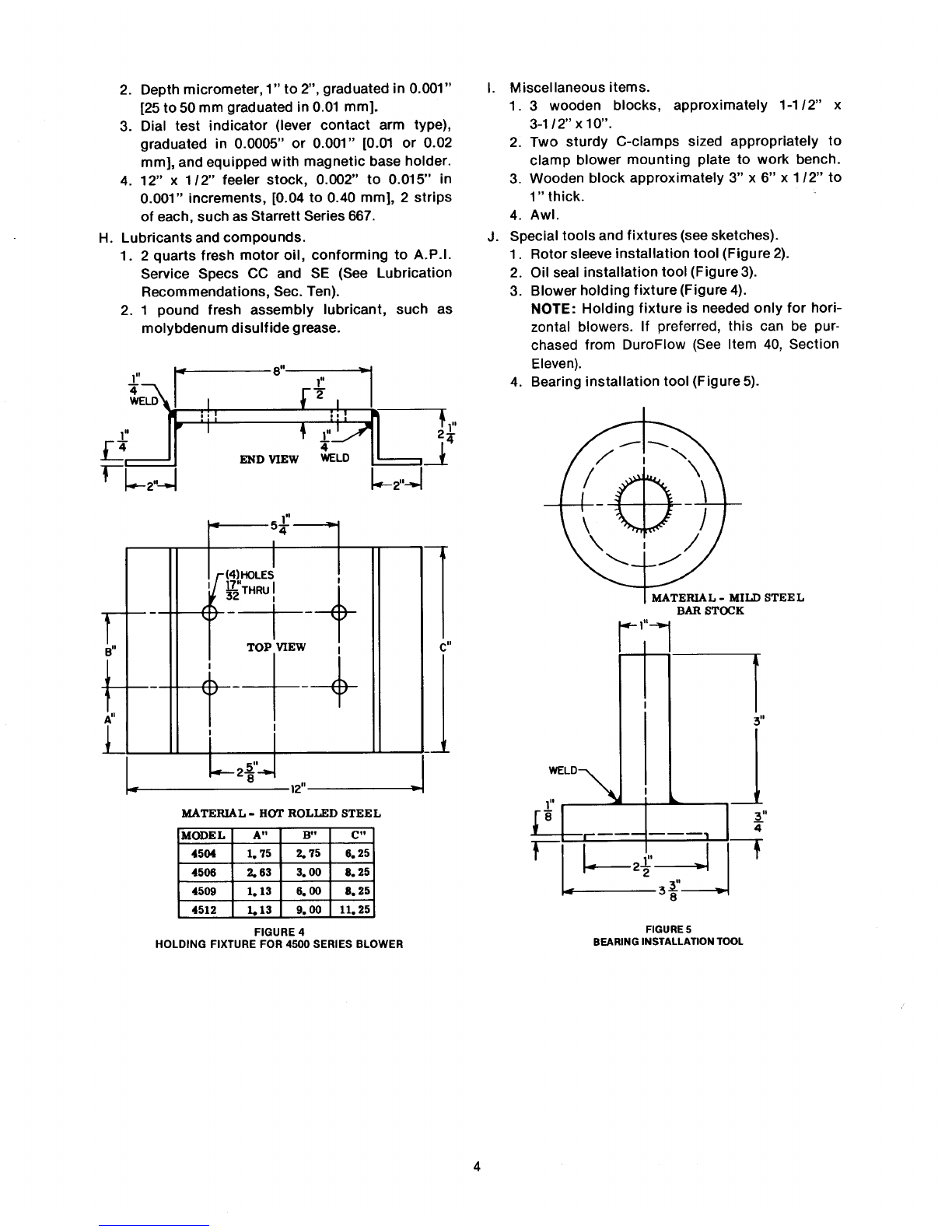

In addition, if overhauling either the HL or HR

versions, it is advisable to use aholding fixture to

secure the blower to the workbench. This can be

obtained from DuroFlow or it can be fabricated as in

Fig. 4.

It is suggested that the appropriate sections of this

manual be read and fully comprehended before any

specific service operation is attempted. Further, the

importance of aclean and adequately outfitted

workshop cannot be overemphasized. The success of

any major blower service effort depends upon

recognition of the fact that virtually every part

contained in the assembly is highly precise, and

hence, is vulnerable to the damaging effects of dirt,

moisture and rough handling.

IMPORTANT NOTICE

In mid-1981, modifications to the 45 Series end plates were made that are not shown in the text of this manual.

Blowers now require only one conventional breather cap. This difference will not affect service procedures.

When properly mounted, the air breather ports on modified blowers are always facing downward, and no

longer require breather caps. If these vent ports are threaded, abreather vent will be inserted. DO NOT PLUG

OR OBSTRUCT THESE AIR VENT PASSAGEWAYS!!

The oil sump breathing is now accomplished through the oil fill port. Ahexagonal bushing is inserted into the

oil fill hole, and the blowers’ only breather cap is placed in this bushing to vent the oil sump.

2