Table of Contents

Keg King....................................................................................................................................................................... 5

Introduction ................................................................................................................................................................. 6

Unboxing...................................................................................................................................................................... 6

Included Items ........................................................................................................................................................ 6

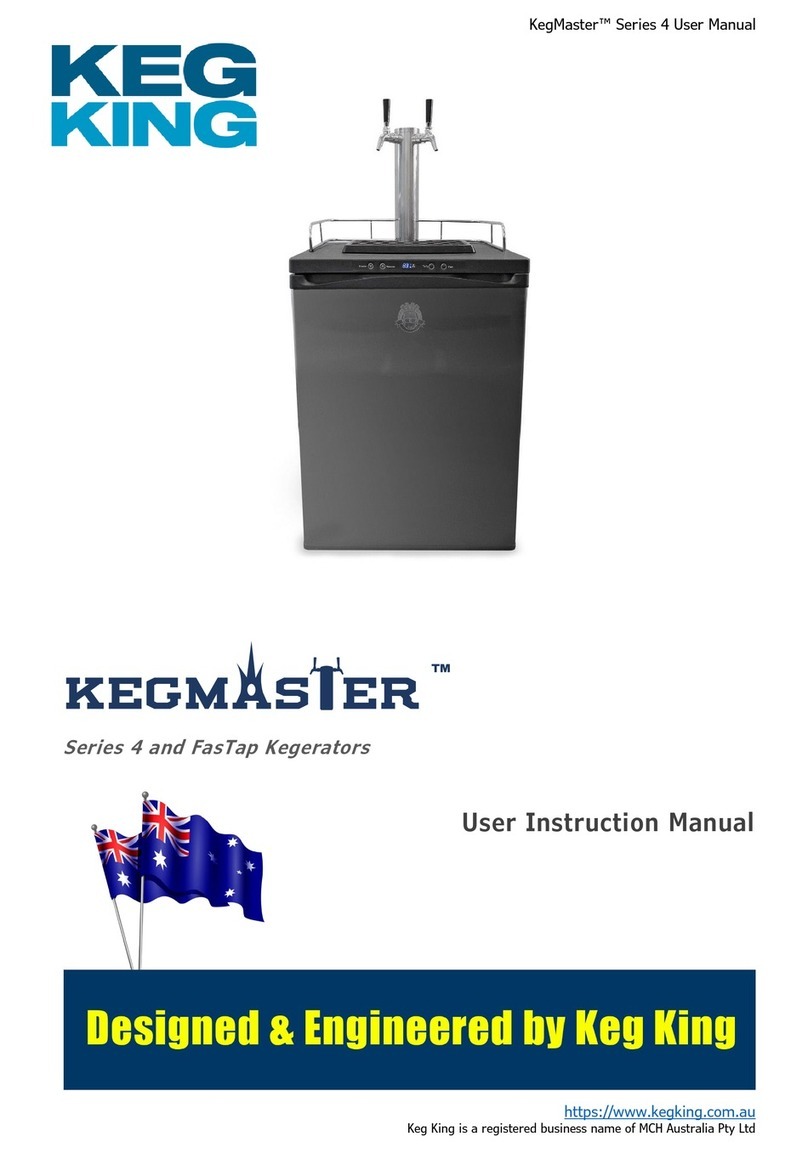

Getting to Know the Unit........................................................................................................................................... 7

The Control Panel................................................................................................................................................... 7

Initial Set Up ................................................................................................................................................................ 7

Door Orientation..................................................................................................................................................... 8

Defrosting the KegMaster™XL................................................................................................................................. 9

Calibrating your KegMaster™Series XL Kegerator............................................................................................... 9

When to calibrate your KegMaster™Series XL Kegerator............................................................................... 9

How to calibrate your KegMaster™Series XL Kegerator?............................................................................... 9

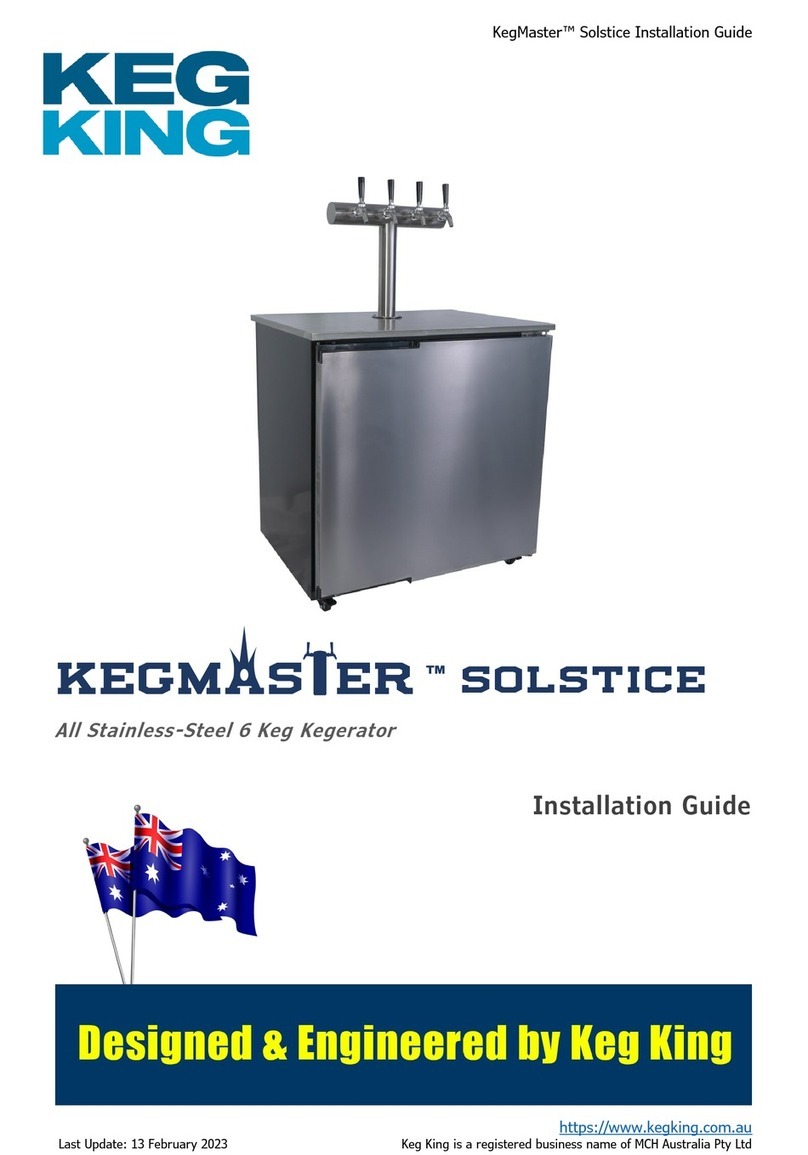

About Kegs and Kegerators .................................................................................................................................... 10

Commercial Kegs ................................................................................................................................................. 10

A-Type................................................................................................................................................................ 10

D-Type ............................................................................................................................................................... 10

S-Type ................................................................................................................................................................ 10

Setting up Commercial Keg Couplers ........................................................................................................... 11

Home Brewing Kegs ............................................................................................................................................ 11

Ball Lock ............................................................................................................................................................ 11

Pin Lock ............................................................................................................................................................. 11

Setting Up Beer and Gas Lines............................................................................................................................... 12

Using Stepless Clamps......................................................................................................................................... 12

Using Push-In Fittings.......................................................................................................................................... 12

Plumbing your Kegerator .................................................................................................................................... 13

For Home Brew Kegs (Ball or Pin Lock Disconnects)................................................................................ 13

For Commercial Kegs (usually 50L) .............................................................................................................. 13

Balancing your Keg System with CO2............................................................................................................... 14

Carbonation Level ............................................................................................................................................ 14

Keg Storage Temperature............................................................................................................................... 14

Beer line diameter and length adjustment.................................................................................................... 14

CO2Conversion Chart ..................................................................................................................................... 15

Attaching and Removing Taps from the Font ............................................................................................. 16

IMPORTANT –C02Pressure Check ................................................................................................................. 16

CO2Consumption Rate.................................................................................................................................... 16

Additional Keg King KegMaster™Accessories .................................................................................................. 17

Troubleshooting........................................................................................................................................................ 18

Specifications............................................................................................................................................................. 18