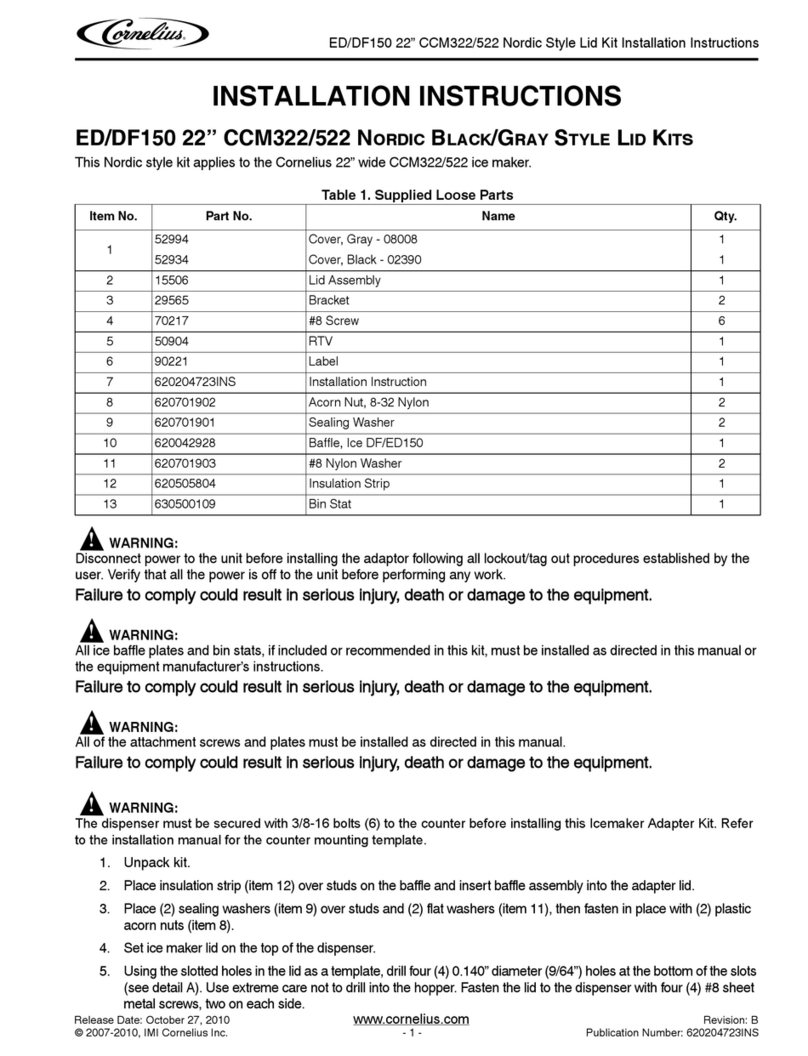

INSTALLATION INSTRUCTIONS CONT'D.

E. REMOTE CONDEWSERS

Remote condensers should be installed above the ice machine in a

leva1 configuration.

by

copper tubing and line valves.

is

mounted qn,tbe ice making unit and the remote condenser. The

female half is soldered on the tube ends when tubing kits are

provided with the machine.

If

tubing kits are not provided, the

female half

of

the line valves will be provided in

a

valve kit

and the installer will mount them on the tubing he provides.

They are connected to the ice making unit

The

male half of the line valve

1.

2.

3.

4.

5.

6.

PLEASE NOTE THE FOLLOWING IN REGARD

TO

REMOTE CONDENSER INSTALLATION:

WHEN MAKING LINE VALVE CONNECTIONS, LUBRICATE RUBBER SEAL IN

MALE

HALF

WITH REFRIGERATION OIL.

TOGETHER BY

HAND

TO INSURE PROPER MATING OF THREADS.

PROPER SIZE WRENCHES (ON COUPLING BODY

HEX

AND TIGHTEN UNTIL COUPLING BODIES "BOTTOM" OR A DEFINXTE

RESISTANCE

IS

FELT. USING

A

MARKER

OR

INK

PEN,

biARK

A

LINE

LENGTHWISE FROM

THE

COUPLING

HEXT

TO THE BULKHEAD. THEN

TIGHTEN

AN

ADDITIONAL

1/6

TO

1/4

TURN. THE MXSALICNMENT

OF

THE

LINE

WILL

SHOW THE DEGREE

OF

TIGHTENING.

THIS

FINAL

TURN

IS

NECESSARY TO INSURE

THAT

THE KNIFE EDGE

METAL

SEAL

BITES

INTO

THE BRASS SEAT OF

THE

COWLING HALVES FORMING THE

LEAKPROOF JOINT. IF TORQUE WRENCH

IS

USED, TORQUE TO

35

FOOT POUNDS.

I

A LOW VOLTAGE ELECTRICAL CONTROL CIRCUIT MUST

BE

FIELD

WIRES

BETWEEN THE ICE MACHINE AND THE REMOTE CONDENSER RELAY. THOSE

WIRES

SHOULD BE RUN WITH THE TUBING DURING INSTALLATION. REFER

TO APPLICABLE WIRING DIAGRAMS.

THE REMOTE ,CONDENSER REQUIRES A SEPARATE POWER SUPPLY FROM

THE

ICE MAKING UNIT. REFER TO THE REMOTE CONDENSER ON

WIRING DIAGRAM.

WHEN VERTICAL LINES

ARE

INVOLVED IN THE INSTALLATION, FOLLOW

STANDARD REFRIGERATION PRACTICES FOR VERTICAL LINES TO &XJJRE

POSITIVE OIL RETURN TO

THE

COMPRESSOR.

NO

MORE

THAN

15

FEET.

WE

DO NOT RECOMMEND TUBING RUNS OF MORE THAN

40

FEET.

THREAD COUPLING HALVES

USE

AND

ON UNION NUT)

b

VERTICAL LIFT TO BE

A THREE WAY HEAD PRESSURE CONTROL VALVE IS USED

TO

MAINTAIN

A

RELATIVELY CONSISTENT

HEAD

PRESSURE BETWEEN

180

AND

200

PSI

FOR

R-22

IN THE RECEIVER IN COLD AMBIENT CONDITIONS TO INSURE

A

GOOD HARVESTING OR DEFROSTING

OF

THE

ICE

SLABS

ON

THE

EVAPORATOR.

BE HELD IN

THE

CONDENSER.

BECAUSE

OF

THIS VALVE

SOME

LIQUID REFRIGERANT WILL

TZIE HEAD PRESSURE CONTROL VALVE WILL,NOT OPERATE CORRECTLY

WHEN

A

TOTAL PRESSURE DROP OF

14

POUNWOR

MORE

IS

CREATED

THE ICE WING UNIT UTILIZING A REMOTE CONDENSER IS SHIPPED FROM

THE FACTORY WITH THE RECEIVER HOLDING THE REFRIGERANT CHARGE.

ADDITIONAL REFRIGgRANT

MAY

BE REQUIRED UPON INSTALLATION DEPEND-

5

ING UPON THE AMBINET CONDITIONS THE REMOTE CONDENSER

IS

OPERATING UNDER, THE CONDENSER AND LINE SIZING.