i569000246

TABLE OF CONTENTS

Page

SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RECOGNIZE SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNDERSTAND SIGNAL WORDS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOLLOW SAFETY INSTRUCTIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CO2 (CARBON DIOXIDE) WARNING 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SHIPPING, STORING, OR RELOCATING UNIT 1. . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY REFERENCE INFORMATION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DESIGN DATA 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THEORY OF OPERATION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNPACKING AND INSPECTION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SELECTING LOCATION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

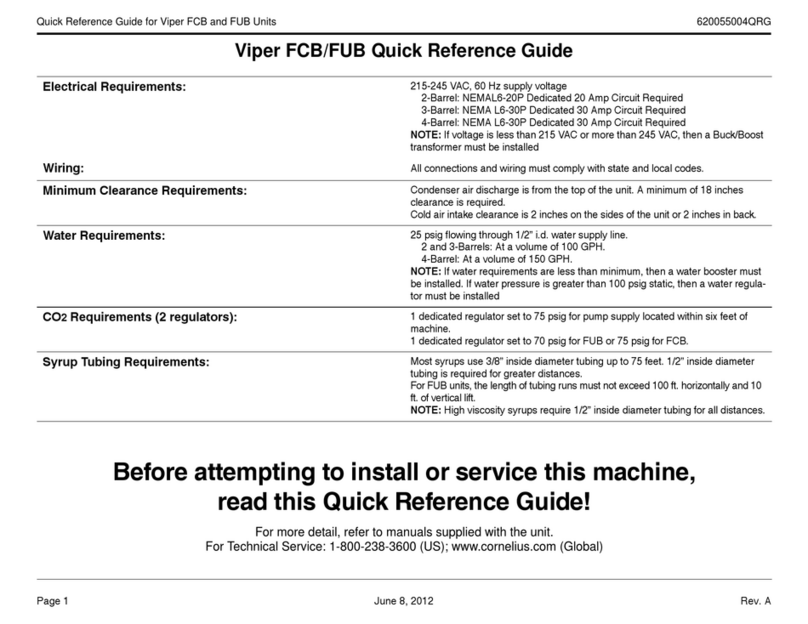

INSTALLING ELECTRICAL OUTLET (ITEM 4) 8. . . . . . . . . . . . . . . . . . . . . . . . . . .

SEALING UNIT TO FLOOR REQUIREMENT (UNIT NOT EQUIPPED WITH

HANDLE AND WHEELS) 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FILL WATER TANK AND START REFRIGERATION SYSTEM 8. . . . . . . . . . . . . .

CONNECTING CO2 SYSTEM TO BEER KEG TAPPERS 9. . . . . . . . . . . . . . . . .

CONNECTING BEER SOURCE SUPPLIES TO UNIT 9. . . . . . . . . . . . . . . . . . . . .

PREPARING UNIT FOR OPERATION 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT OPERATION 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATOR’S INSTRUCTIONS 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROPER BEER STORAGE 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATING CONTROLS 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEER FAUCET 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT POWER SWITCH (115 VAC, 60 HZ UNIT ONLY) 11. . . . . . . . . . . . . . . . . . . .

UNIT OPERATION 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY PRE-OPERATION CHECK 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATING CLEARANCES 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENTS 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING CO2 REGULATORS 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING DISPENSED BEER FLOW RATE 12. . . . . . . . . . . . . . . . . . . . . . . . . . .

COOLING UNIT MAINTENANCE 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING CONDENSER COIL 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECKING ICE WATER BATH 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING AND SANITIZING 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY CLEANING 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING BEER SYSTEMS 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPLENISHING CO2 SUPPLY 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPLENISHING BEER SUPPLY 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING CO2 SYSTEM GAS CHECK VALVES 13. . . . . . . . . . . . . . . . . . . . . . . . . .