Standard Recommended Procedure 003-1069-AEN | Issue 1 | July 2019 | Page 2 of 6

2. Tools Required

• Phillips-head screwdriver

• Scissors

• 216B tool (can wrench)

• Pencil, pen or marker

3. Additional Materials (Purchased Separately)

May or may not be required depending on your application.

• Grounding kit (HDWR-GRND-KIT)

• Inner door lock kit (HDWR-LOCK-KIT)

• Padlock for front door

• Mounting hardware

• Buer tube fan-out kit (FAN-XX25-YY)

• CCH splice cassette (CCH-CSXX-YY-P00ZZ)

4. Mount the Housing

Step 1: Select a at vertical surface to prevent warping.

Step 2: Determine mounting location.

Step 3: Use a pencil, pen, or marker to mark the wall through the holes in the mounting brackets.

Step 4: Set unit aside and drive the mounting hardware (not provided) in at these locations leaving a 1/8-in

gap.

Step 5: Place housing on mounting hardware and tighten.

5. Housing Preparation (to maintain NEMA ratings)

IMPORTANT: If you are installing outside plant cable or temperature uctuates widely along any part of the

cable, the strength members of the cable must be strain-relieved. Failure to do so may result in

damage to the cable as temperature varies. Other situations only require the cable to be strain-

relieved by sheath retention only.

5.1 Install cord connectors

Step 1: Remove the grommets or knockouts, as applicable.

Step 2: Install cord connector with the knurled nut on the

outside of the housing.

Step 3: Orient the washers so that there is a gap between them

in the center as they are clamped together.

Step 4: Secure the cord connector on the inside of the housing

using the provided lock nut.

Step 5: Thread the cable through the tting and tighten the nuts.

5.2 Install conduit ttings

Step 1: Feed the cable through the ttings with the lager portion of the

tting on the outside of the housing and the smaller tting on the

inside.

Step 2: Screw the two ttings together.

IMPORTANT: For strength member strain-relief, use OSE-CBL-3X as the cable entry port tting. Install according

to the instructions provided with the kit.

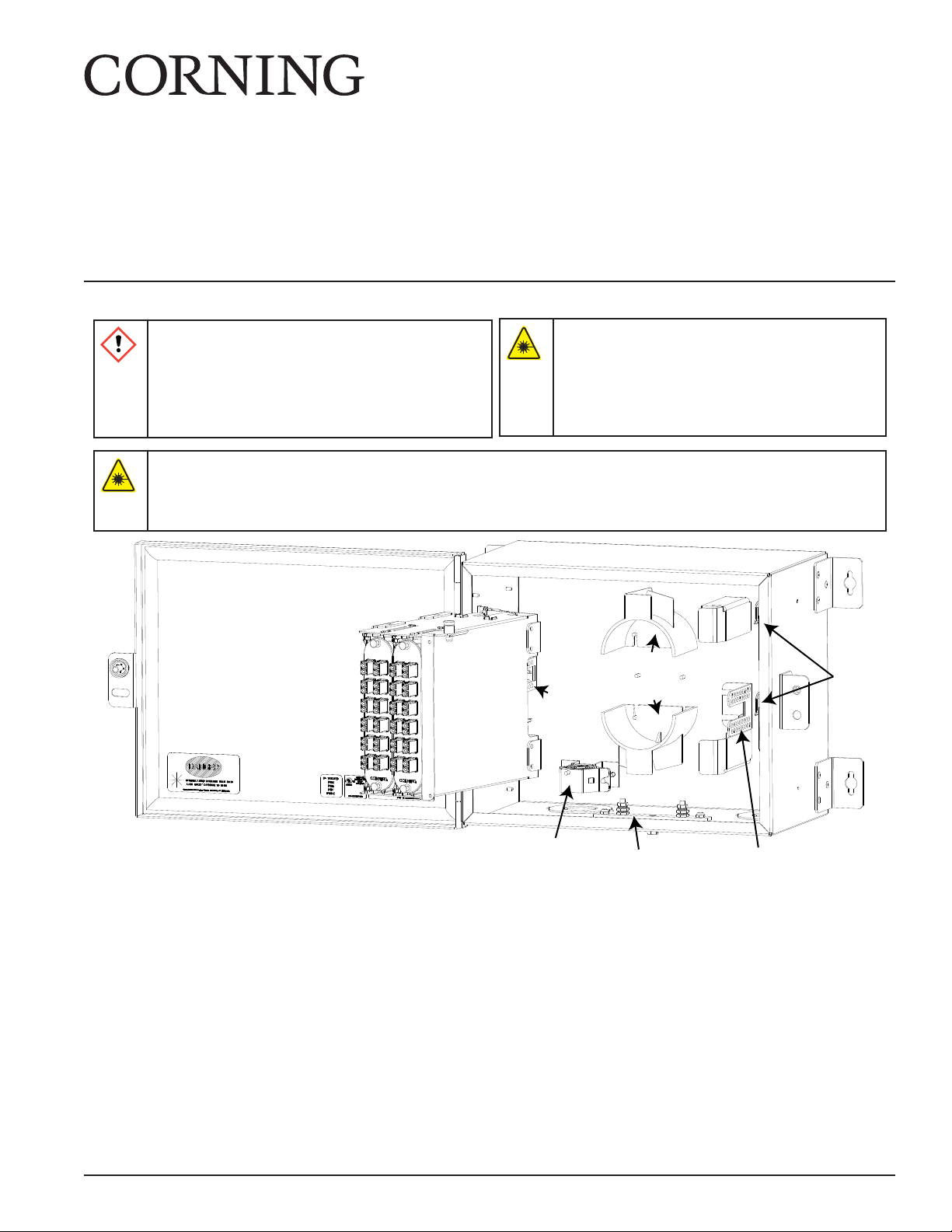

Mounting Screws Not Provided

TPA-6575

Housing

Lock Nut

Reducing

Washer

Cord

Connector

Knurled

Nut

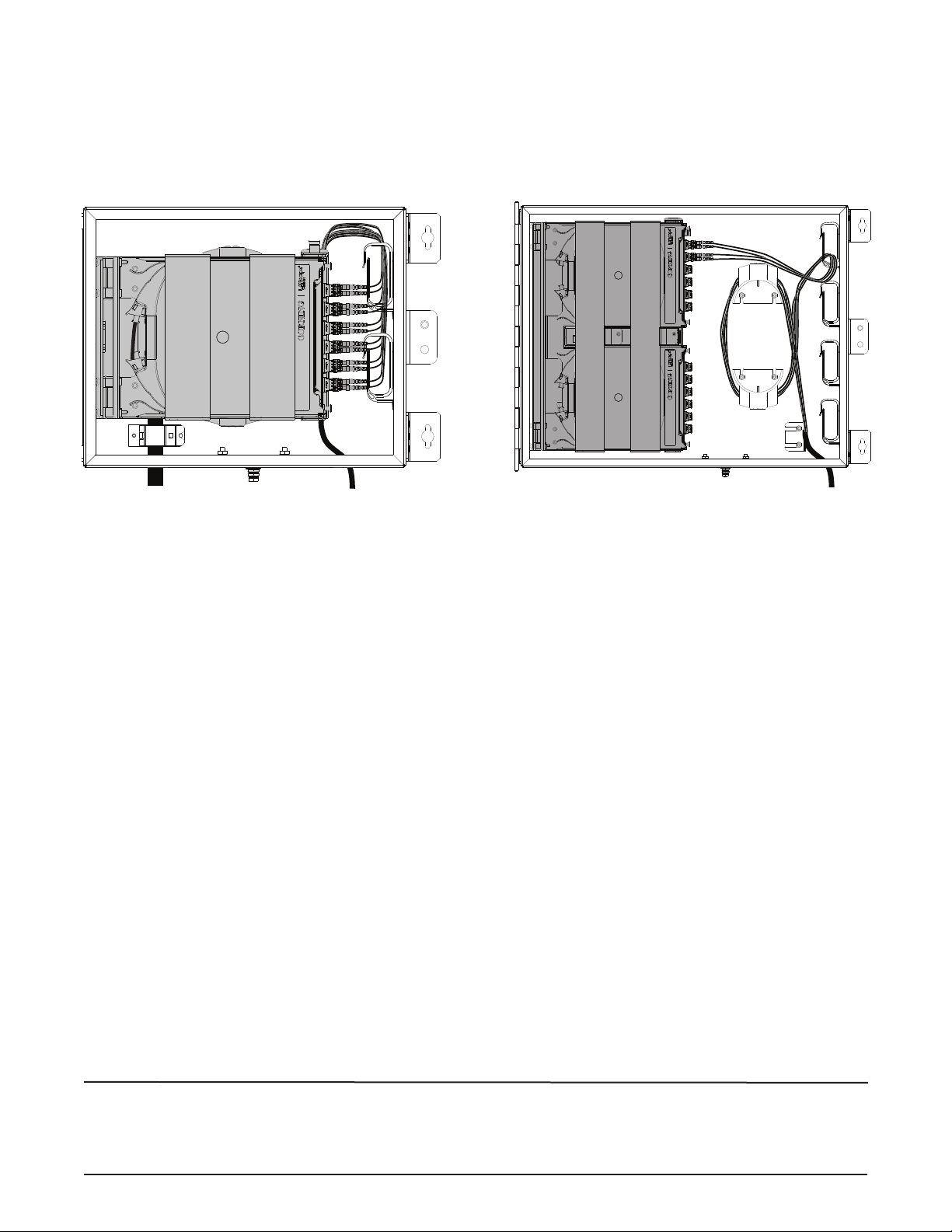

KPA-2176

KPA-2177