Corning Cable Systems

Standard Recommended Procedure (SRP) 003-485

Issue 6, October 2006

Page 1 of 32

SCF-6 Canister and Inline Splice Closures

p/n 003-485

Contents

Related Literature ................................................................................................................... 2

Admonishments.......................................................................................................................3

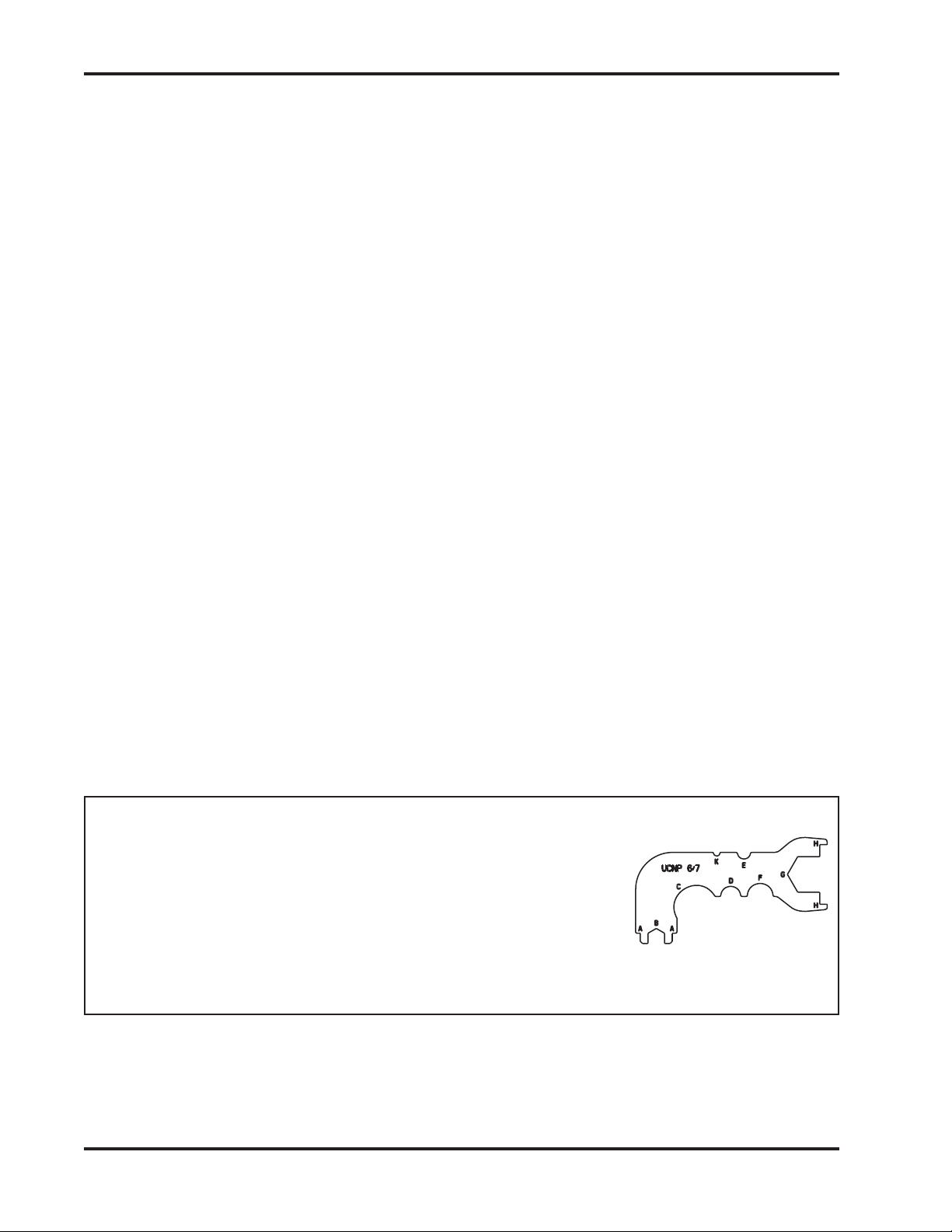

1. Product information .........................................................................................................................3

2. Carton Contents ...............................................................................................................................4

2.1 SCF-6C Closure Contents .....................................................................................................4

2.2 SCF-6T Closure Contents ..................................................................................................... 4

3. Description of Kits ........................................................................................................................... 5

3.1 Accessory kit (p/n SCF-6C-ACCY) .......................................................................................5

3.2 Accessory kit (p/n SCF-6T30-ACCY) ................................................................................... 6

3.3 Accessory kit (p/n SCF-6T40-ACCY) ................................................................................... 7

4. Tools and Materials Required ..........................................................................................................8

5. Installing the Closure .......................................................................................................................9

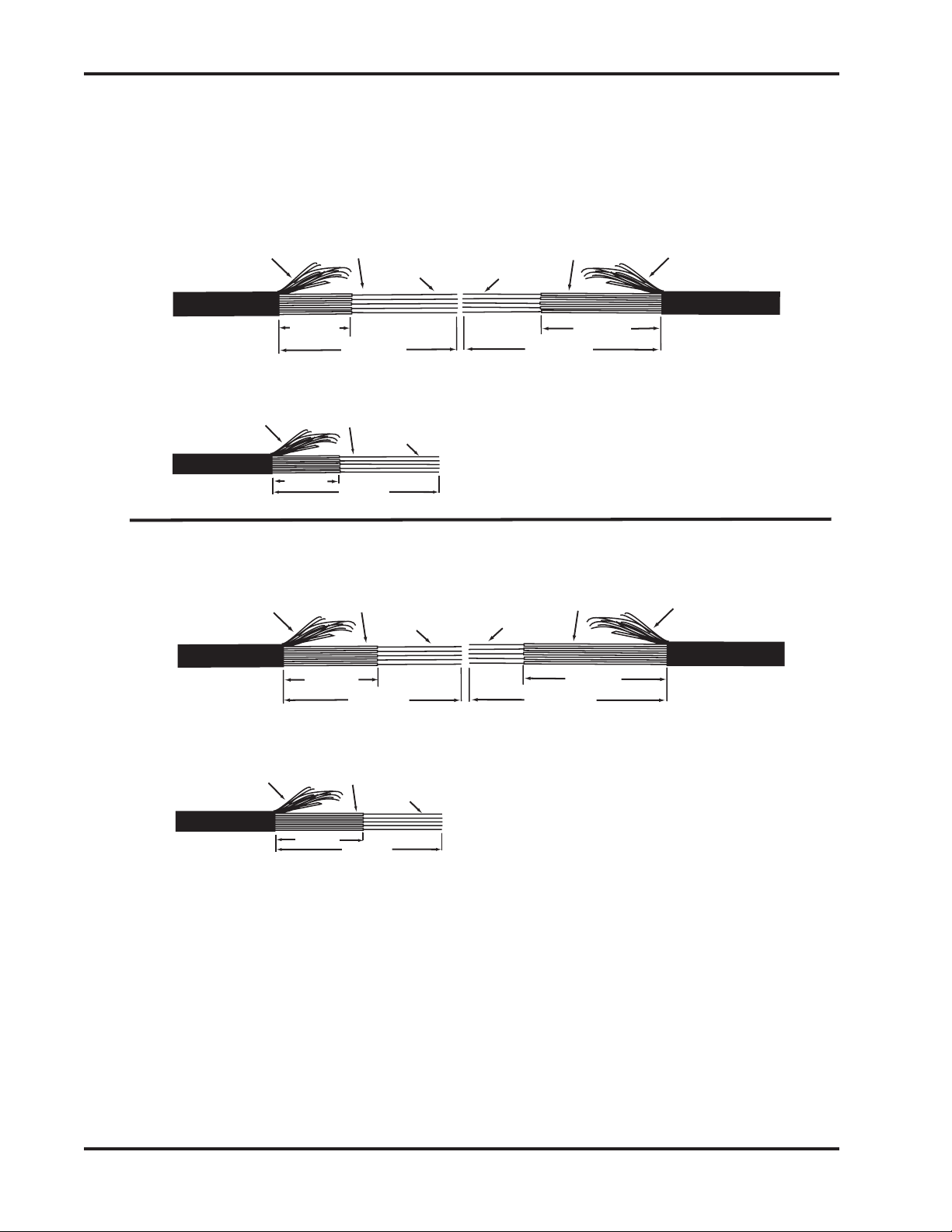

5.1 Prepare the Express Cable ......................................................................................................9

5.2 Install Grounding Hardware (Armored Cable Only) ..........................................................11

5.3 Install Express Strain-relief Hardware ................................................................................. 12

5.3.1 Strain-relief bracket(s) ................................................................................................ 12

5.3.2 Nonmetallic strength member ................................................................................... 13

5.3.3 Metallic strength members ......................................................................................... 13

5.3.4 Large strength members............................................................................................. 14

5.4 Install Cable into the End Cap Express Ports ......................................................................15

5.4.1 Prepare the end cap .................................................................................................... 15

5.4.2 Apply sealing tape to the cable ................................................................................... 16

5.4.3 Use a dummy plug ...................................................................................................... 17

5.4.4 Install cable ................................................................................................................. 17

5.4.5 Close end cap halves ...................................................................................................18

5.4.6 Install vented grounding screw................................................................................... 19

5.5 Ground Armored Cable ........................................................................................................ 19

5.6 Prepare Drop Cable Port(s) ..................................................................................................19

5.7 Install Drop Port Cable into End Cap .................................................................................20

5.8 Strain-relieve Drop Port Cables ........................................................................................... 21

5.9 Complete Frame Assembly ...................................................................................................22

5.10 Attach Strain-relief Bracket ..................................................................................................22

5.11 Tighten End Cap Compression Screw................................................................................. 22

5.12 Splice .....................................................................................................................................22

5.12.1 Prepare fiber for splicing .......................................................................................... 22

5.12.2 Store cable slack ........................................................................................................23

5.12.3 Secure spliced trays ...................................................................................................23

5.13 Seal the Inline Closure ..........................................................................................................24

5.13.1 Install sealing gasket .................................................................................................24

5.13.2 Prepare closure cover................................................................................................26