Corning Cable Systems

Standard Recommended Procedure (SRP) 003-544

Issue 6, May 2004

Page 1 of 26

SCF-6 and SCF-8 Open Ribbon System (ORS) Canister Splice Closures

p/n 003-544

SCF-8

Figure 1 — Splice Closures

SCF-6

Contents

Related Literature ...................................................................................................................2

Admonishments.......................................................................................................................2

1. Carton Contents ...............................................................................................................................3

2. Tools and Equipment Required .......................................................................................................4

3. Installing the Closure .......................................................................................................................4

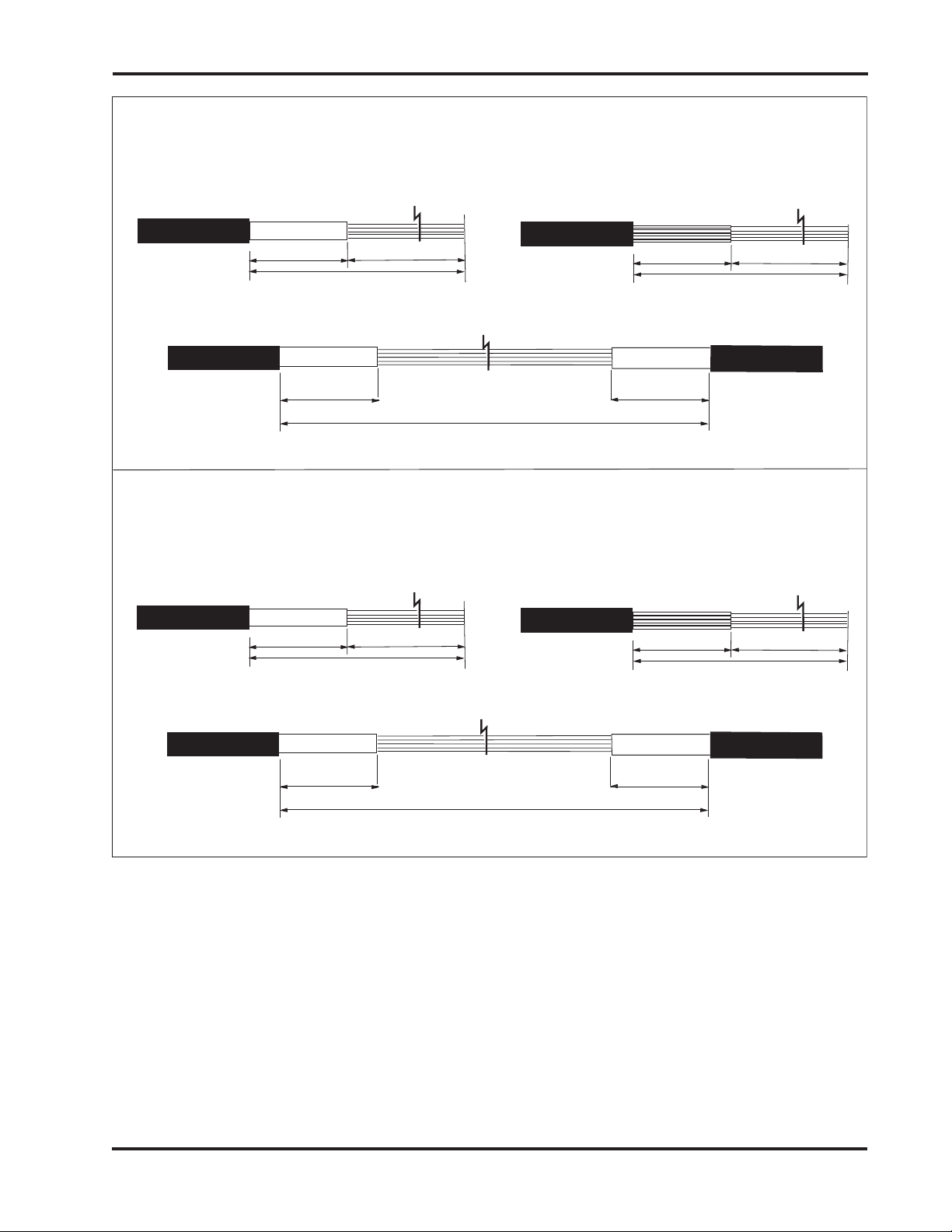

3.1 Prepare the Express Cable ......................................................................................................4

3.2 Install Grounding Hardware (Armored Cable Only) ............................................................6

3.3 Install Express Strain-relief Hardware ................................................................................... 7

3.3.1 Strain-relief bracket(s) ................................................................................................7

3.3.2 Nonmetallic strength member ...................................................................................8

3.3.3 Metallic strength members ........................................................................................8

3.3.4 Large strength members ............................................................................................9

3.4 Install Cable into the End Cap Express Ports ........................................................................ 9

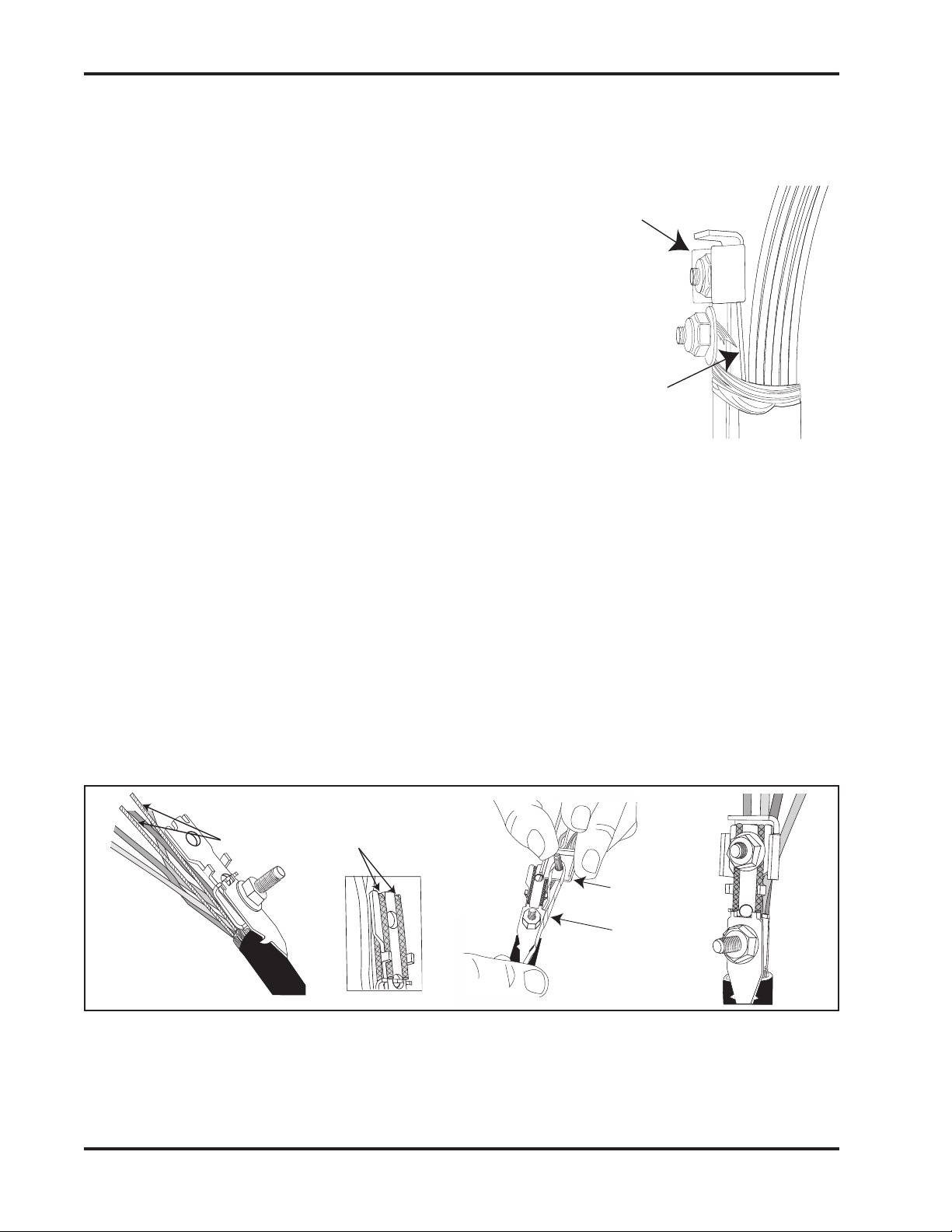

3.4.1 Prepare the end cap ....................................................................................................9

3.4.2 Apply sealing tape to the cable ................................................................................. 10

3.4.3 Using dummy plug ...................................................................................................11

3.4.4 Install cable ...............................................................................................................11

3.4.5 Close end cap halves .................................................................................................11

3.4.6 Install vented grounding plug ..................................................................................12

3.4.7 Complete frame assembly ........................................................................................12

3.5 Ground Armored Cable ........................................................................................................12

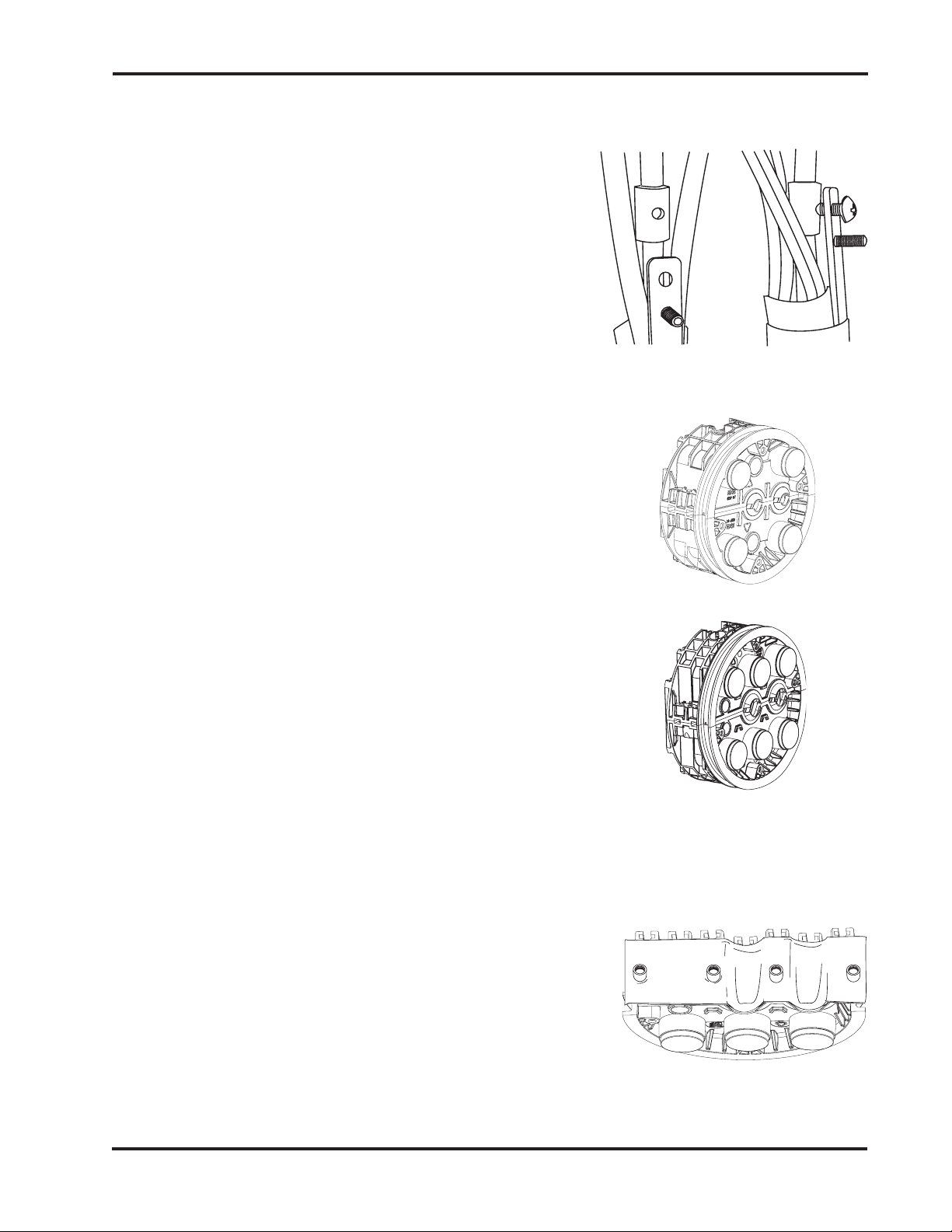

3.6 Prepare Drop Cable Port(s) ..................................................................................................12

3.7 Install Drop Port Cable into End Cap .................................................................................14

3.8 Strain-relieve Drop Ports .....................................................................................................14

3.9 Attach Strain-relief Bracket ..................................................................................................15

3.10 Tighten End Cap Compression Screw.................................................................................15

3.11 Attach Frame to End Cap .....................................................................................................16

3.12 Load the ORS .......................................................................................................................16

3.12.1 Route express fibers ..................................................................................................16

3.12.2 Route drop cable fibers ............................................................................................18

3.12.3 Route fibers to the splice plane ................................................................................18

3.13 Splice .....................................................................................................................................19

3.13.1 Prepare fibers for splicing ........................................................................................ 19

3.13.2 Splice fibers...............................................................................................................19