3

DEC 2021

INSTALL GUIDE

1

INSTALLATION

COGNEX DataMan 374

REV 00

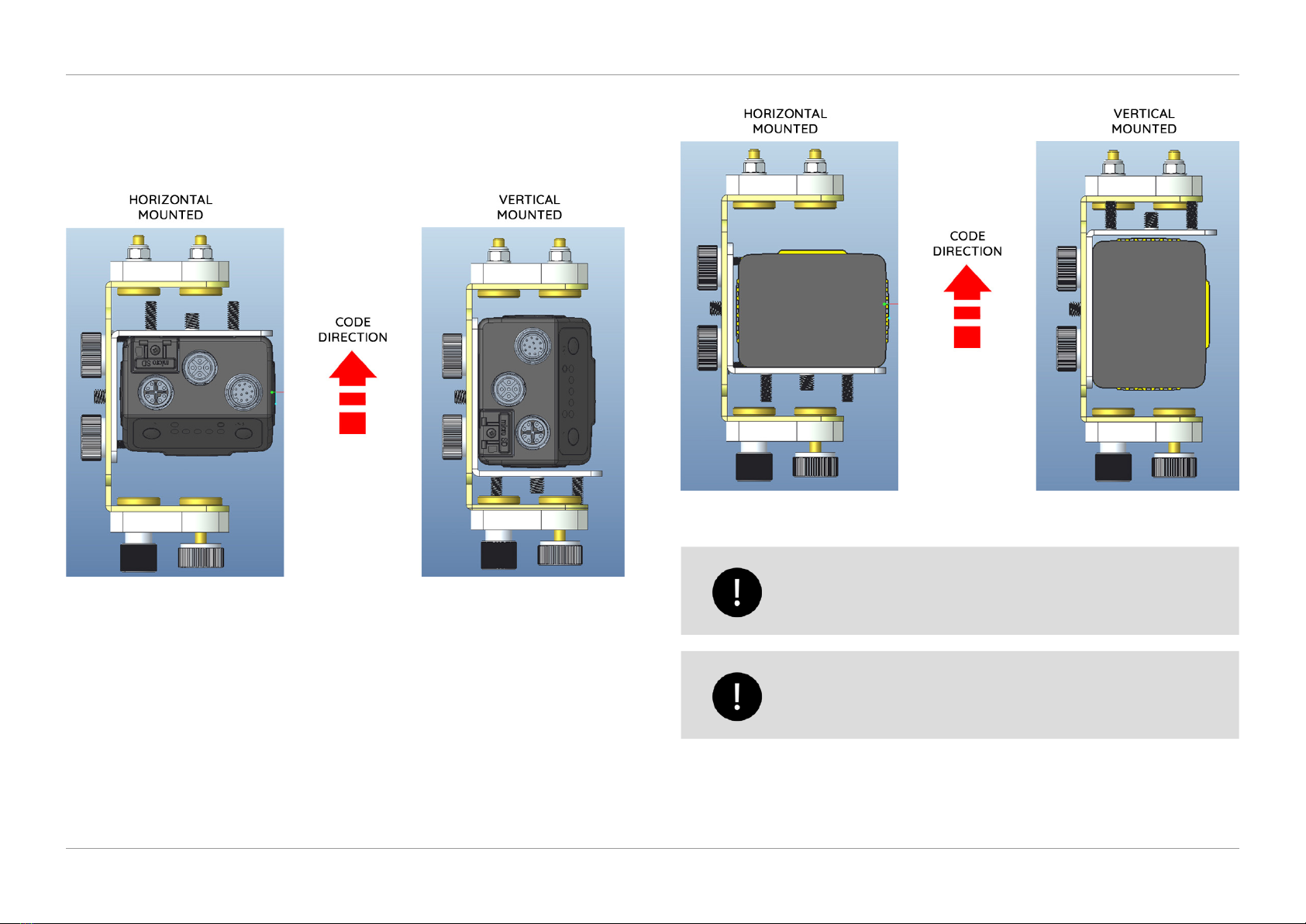

1.1.1 MOUNTING HEIGHT

1. To set the height, attach the Cognex Reader assembly to the Vertical Head

Bracket (9107481J).

2. Ensure the reader mount ‘lug’ locates into position for either top-read or

bottom-read as shown in Figure 1.3.

QTL-RND-OPS-00000303-A-00

Figure 1.3 – Reader mount lug located into position

3. Attach the Reader assembly to the vertical head bracket with the two thumb

lock knobs.

Bracket mount must be orientated correctly to achieve a nominal

distance of 110mm from the paper surface.

1.1.2 MOUNTING ANGLE

1. To set the angle, un-tighten the thumb lock knob for either top-read or

bottom-read as shown in Figure 1.4.

QTL-RND-OPS-00000304-A-00

Figure 1.4 – Un-tightening the thumb lock knobs

The small thumb lock knob allows adjustment of the angle, and

the larger thumb lock knob allows adjustment of the side to side

position.