CAT820R 2 Rev. 12/18/15

FAILURE TO OBSERVE THESE WARNINGS COULD RE SULT IN IN JU RY.

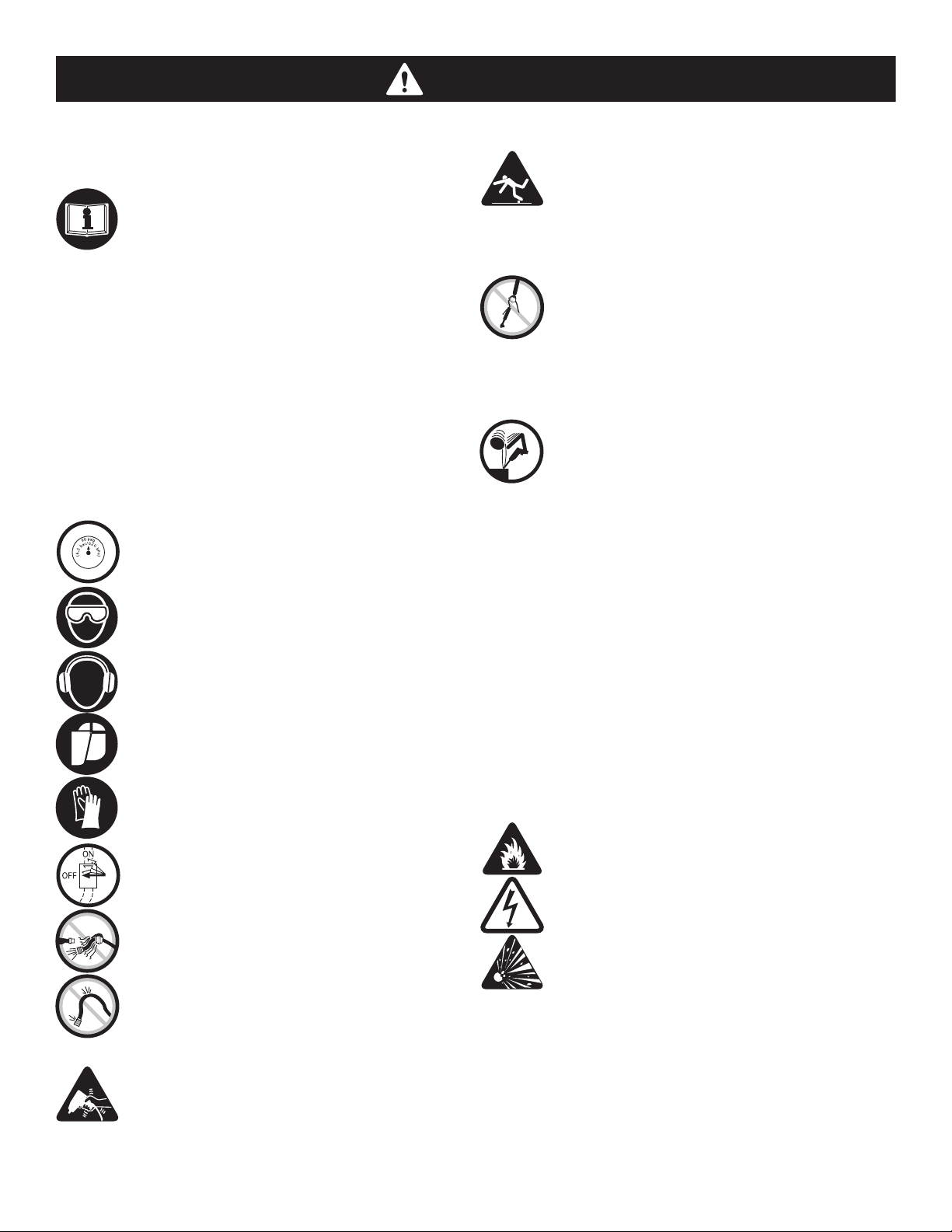

THIS INSTRUCTION MANUAL CONTAINS

IMPORTANT SAFETY INFORMATION.

READ THIS INSTRUCTION MANUAL CAREFULLY

AND UNDERSTAND ALL INFORMATION BEFORE

OPERATING THIS TOOL.

• Itistheresponsibilityoftheownertomakesureall

personnelreadthismanualpriortousingthisairtool.

Itisalsotheresponsibilityoftheairtoolownerto

keepthismanualintactandinaconvenientlocation

foralltoseeandread.Ifthemanualorproductlabels

arelostornotlegible,contactCornwellforreplacements.

IftheoperatorisnotfluentinEnglish,theproductand

safetyinstructionsshallbereadtoanddiscussed

withtheoperatorintheoperator'snativelanguageby

thepurchaser/ownerorhisdesignee,makingsure

thattheoperatorcomprehendsitscontents.

• Alwaysoperate,inspectandmaintainthistoolin

accordancewithAmericanNationalStandards

InstituteSafetyCodeofPortableAirTools(ANSIB186.1)

andanyotherapplicablesafetycodesandregulations.

• Forsafety,topperformanceandmaximumdurability

ofparts,operatethistoolat90psig:6.2barmaxair

pressurewith3/8"diameterairsupplyhose.

• Alwayswearimpact-resistanteyeprotectionwhen

operatingorperformingmaintenanceonthistool

(usersandbystanders).

• Alwayswearhearingprotectionwhenusingthistool

(usersandbystanders).Highsoundlevelscancause

permanenthearingloss.Usehearingprotectionas

recommendedbyyouremployerorOSHAregulation.

• Alwayswearfaceandhandprotectionwhenoperating

thistool.

• Keepthetoolinefficientoperatingcondition.

• Operatorsandmaintenancepersonnelmustbe

physicallyabletohandlethebulk,weightandpower

ofthistool.

• Airunderpressurecancausesevereinjury.Never

directairatyourselforothers.Alwaysturnofftheair

supply,drainhoseofairpressureanddetachtool

fromairsupplybeforeinstalling,removingor

adjustinganyaccessoryonthistool,orbefore

performinganymaintenanceonthistool.Failureto

dosocouldresultininjury.Whiphosescancause

seriousinjury.Alwayscheckfordamaged,frayedor

loosehosesandfittings,andreplaceimmediately.

Donotusequickdetachcouplingsattool.See

instructionsforcorrectset-uponpage4.

• Airpoweredtoolscanvibrateduringuse.Vibration,

repetitivemotionsoruncomfortablepositionsover

extendedperiodsoftimemaybeharmfultoyour

handsandarms.Discontinueuseoftoolifdiscomfort,

tinglingfeelingorpainoccurs.Seekmedicaladvice

beforeresuminguse.

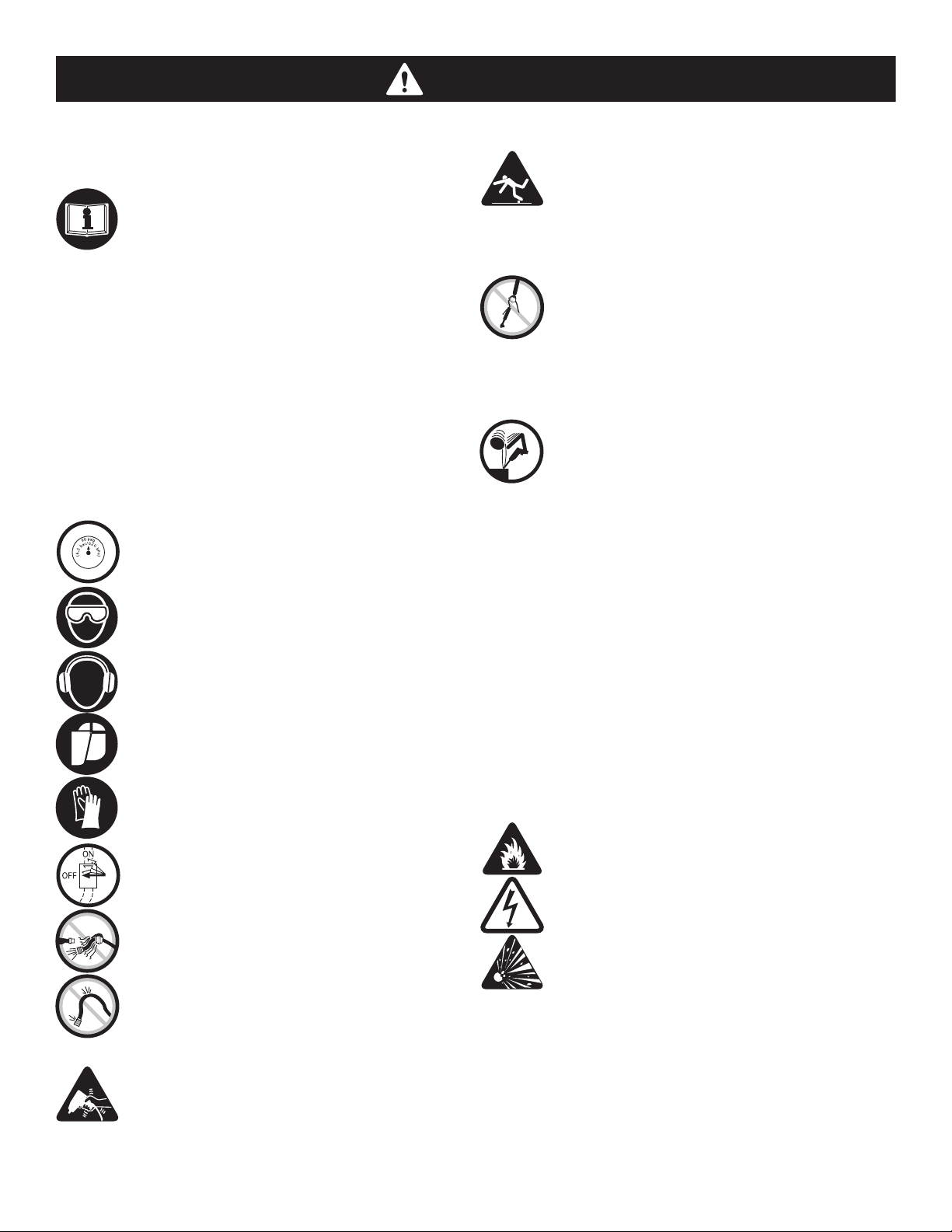

• Slipping,trippingand/orfallingwhileoperatingairtools

canbeamajorcauseofseriousinjuryordeath.Beaware

ofexcesshoseleftonthewalkingorworksurface.

• Keepbodyworkingstancebalancedandfirm.

Donotoverreachwhenoperatingthetool.

• Anticipateandbealertforsuddenchangesinmotion

duringstartupandoperationofanypowertool.

• Donotcarrytoolbythehose.Protectthehose

fromsharpobjectsandheat.

• Toolshaftmaycontinuetorotatebrieflyafterthrottle

isreleased.Avoiddirectcontactwithaccessories

duringandafteruse.Gloveswillreducetheriskof

cutsorburns.

• Keepawayfromrotatingendoftool.Donotwear

jewelryorlooseclothing.Securelonghair.Scalping

canoccurifhairisnotkeptawayfromtooland

accessories.Chokingcanoccurifneckwearisnot

keptawayfromtoolandaccessories.

• NotedirectionofrotationBEFOREoperatingtool.

• Use accessories rated at 18,000 RPM or higher.

• Never operate this tool without required disc

cover/guard in place.

• Do not lock, tape or wire the "on/off" safety lever

in the "on" position, as the lever must be free to

return to the "off" position when released.

• Correctcut-offwheelmountingisnecessaryto

preventinjuryfrombrokenwheels.Donotuse

chippedorcrackedcut-offwheels.Cut-offwheels

shouldbeafreefitonthespindletopreventstress

atthehole.Useonlywheelcollarsthatcomewith

thetoolformountingthecut-offwheel.Flatwashers

orotheradaptersmayoverstressthewheel.Tighten

thewheelonthespindletopreventspinoffwhenthe

toolisturnedoff.

• Donotuse(ormodify)thetoolforanyotherpurpose

thanthatforwhichitwasdesignedwithoutconsulting

themanufacturer'sauthorizedrepresentative.

• Donotlubricatetoolswithflammableorvolatile

liquidssuchaskerosene,dieselorjetfuel.

• Thistoolisnotinsulatedagainstelectricshock.

• Thistoolmustnotbeusedinexplosiveatmospheres.

• Servicingandrepairsshouldonlybemadebyan

authorizedservicecenter.

• Donotforcetoolbeyonditsratedcapacity.

• Use accessories recommended by Cornwell Tools.

• Keeptooloutofreachofchildren.

• Donotremoveanylabels.Replaceanydamaged

labels.

• Thisproductmaycontainoneormorechemicals

knowntotheStateofCaliforniatocausecancerand

birthdefectsorotherreproductiveharm.Wash hands

thoroughly after handling.