CAT3160 4 11/11/14

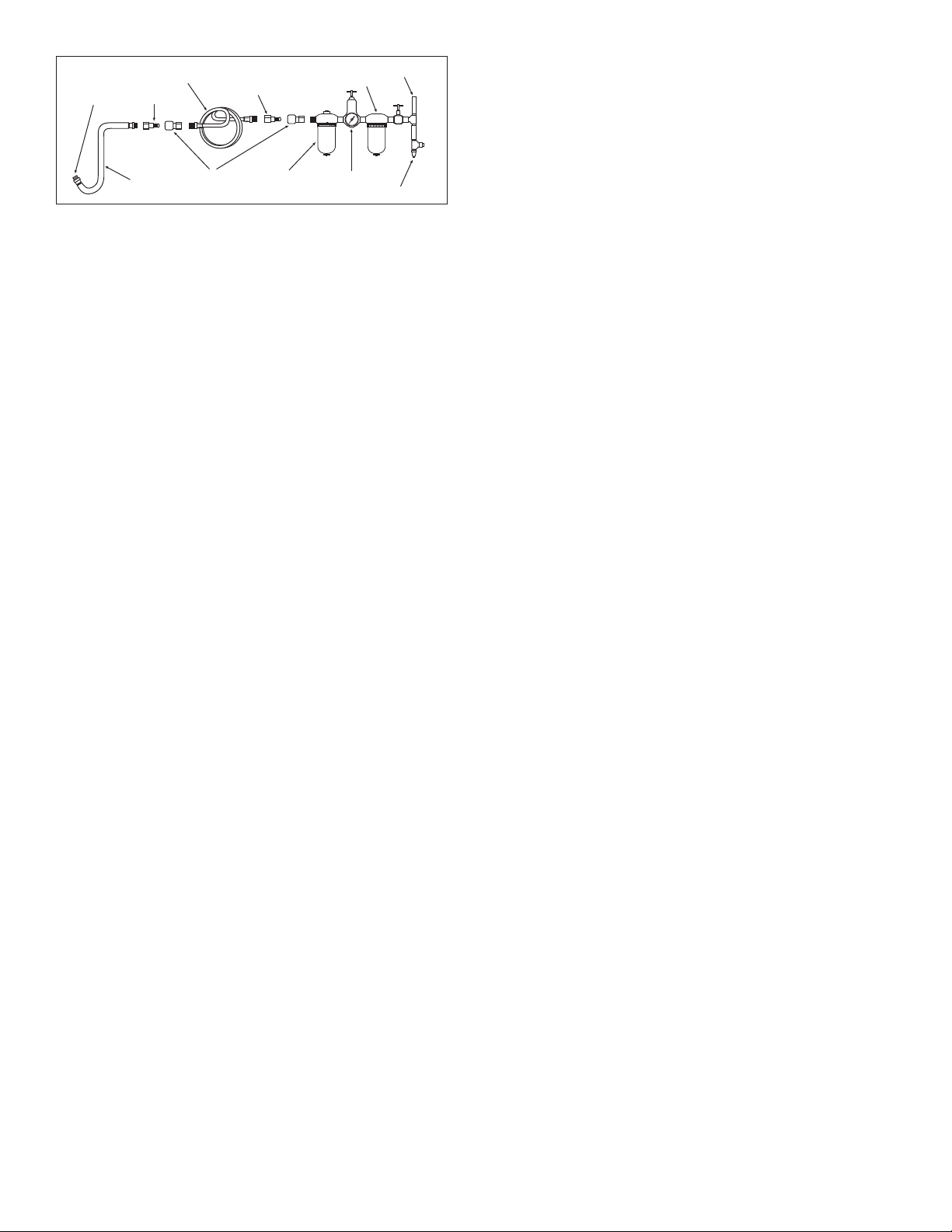

Drain Daily

RegulatorOilerQuick CouplerLeader

Hose

Nipple

Do Not Install

Quick Coupling

Here

Nipple

Filter

Air Supply

Whip Hose

AIR SUPPLY

Toolsoperateonawiderangeofairpressures.Itisrecommended

thatairpressuremeasures90psigatthetoolwiththetriggerfully

depressedandnoloadappliedtothetool.Higherpressure(over90

psig;6.2bar)raisesperformancebeyondtheratedcapacityofthe

tool,whichwillshortentoollifeandcouldcauseinjury.

Alwaysuseclean,dryair.Dust,corrosivefumesand/orwaterinthe

airlinewillcausedamagetothetool.Drainthewaterfromairlines

andcompressorpriortorunningtool.Cleantheairinletfilterscreen

weekly.Therecommendedhookupprocedurecanbeviewedinthe

abovefigure.

Theairinletusedforconnectingairsupplyhasstandard1/4"NPT.

Linepressureshouldbeincreasedtocompensateforunusuallylong

airhoses(over25feet).Minimumhosediametershouldbe3/8"I.D.

andfittingsshouldhavethesameinsidedimensionsandbetightly

secured.

Ensureanaccessibleemergencyshutoffvalvehasbeeninstalledin

theairsupplylineandmakeothersawareofitslocation.

LUBRICATION

Lubricatethe airmotor dailywith highqualityairtool oil.If noair

line oiler is used, run 1/2 oz. of oil through the tool.The oil can

be squirted into the tool air inlet or into the hose at the nearest

connectiontotheairsupply,thenrunthetool.Arustinhibitiveoilis

acceptableforairtools.

WARNING:After an airtool has beenlubricated,oil willdischarge

throughtheexhaustportduringthefirstfewsecondsofoperation.

Theexhaustportmustbecoveredwithatowelbeforeapplyingair

pressuretopreventseriousinjury.

OPERATION

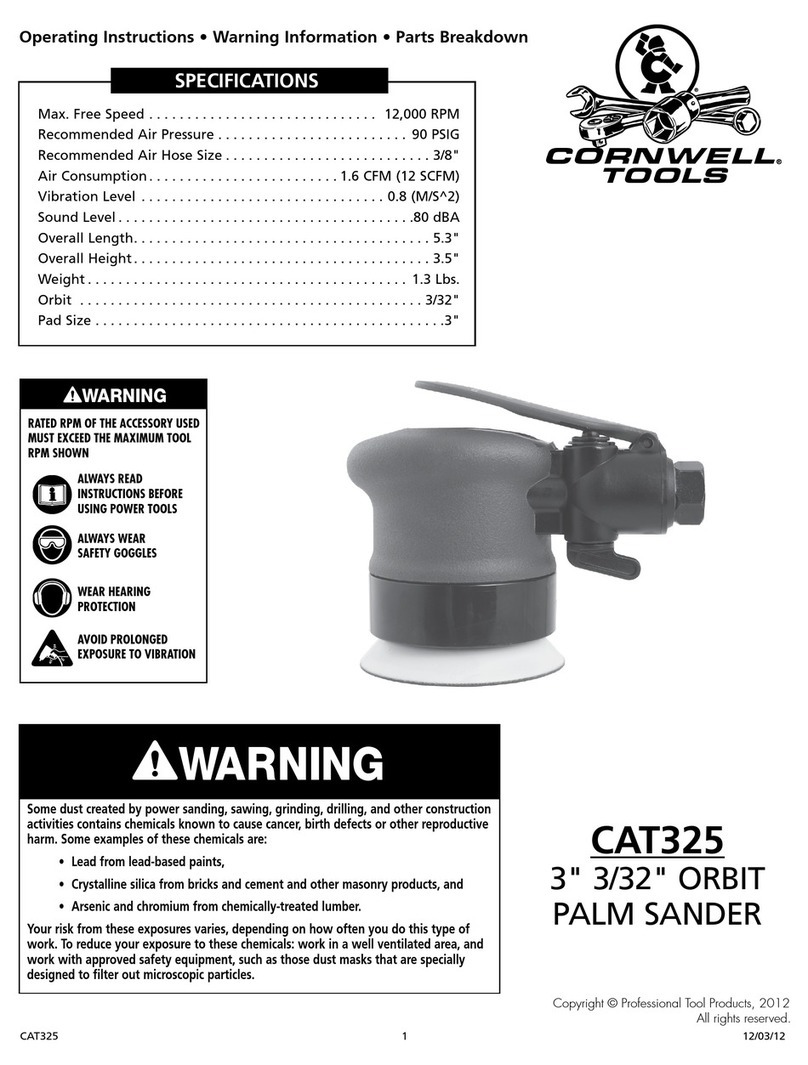

Thisrandomorbitalsanderisdesignedforsmoothingandsanding

paint,fiberglass,wood,andbodyfiller.

Assembly:Tightlymountthepadtothetoolusingthemanufacturer

suppliedspannerwrench.Centerabrasivepaperonpadandpress

firmlytoensureproperadhesion.

Use only a sanding pad, buffing wheel, or polishing bonnet with

thistool.

Donotuseanygrindingwheels,burormetalremovingaccesories

with this tool. NEVER use an accessory having a maximum

operationspeedlessthanthefreespeedofthesanderinwhichit

isbeingused.

Whenusingapadonathreadedarbor,makecertaintheflangenut

istightenedsecurely(wrenchsupplied).Checkthetightnessofthe

flangenutbeforeoperatingtomakecertainitwillnotloosenduring

operation.

Alwaysturnofftheairsupply,drainhoseofairpressureanddetach

toolfromairsupplybeforeinstalling,removingoradjustinganypart

oraccessoryonthistool,orbeforeperforminganymaintenanceon

thistool.

NOTE: During operation, safety goggles should be worn to guard

againstflyingrustandchips(usersandbystanders).

WARNING: After mounting sandpaper, start this Sander under a

benchinordertomakesuresandpaperisfirmlyattached.

TROUBLESHOOTING

Otherfactorsoutside thetool maycauseloss of powerorerratic

action.Reducedcompressoroutput,excessivedrainontheairline,

moistureorrestrictionsinairpipesortheuseofhoseconnections

ofimpropersizeorpoorconditionsmayreduceairsupply.Gritor

gum deposits in the tool may cut power and may be corrected

by cleaning the air strainer and flushing out the tool with gum

solventoiloranequalmixtureofSAE#10andkerosene.Ifoutside

conditionsareinorder,disconnecttoolfromhoseandtaketoolto

yournearestauthorizedservicecenter.

WARRANTY

CornwellQualityToolsCompany(“Cornwell”)warrantsthisproductagainstdefectsinmaterialandworkmanshipforaperiodofONE(1)YEARfromthedateoforiginalretailpurchase.

Subjecttotheconditionsandlimitationssetforthbelow,Cornwellwill,atitsoption,eitherrepairorreplaceanypartoftheproduct(s)thatprovesdefectivebyreasonofimproper

workmanshipormaterials.

This warranty does not cover any damage to this product that results from accident, abuse, misuse, natural or personal disaster, or any unauthorized disassembly, repair, or

modification.Repairs,disassemblyandmodificationareonlyauthorizedtobemadebyCornwelloraCornwellAuthorizedWarrantyCenter.

WARRANTY SERVICE

Inordertohaveyourtoolrepaired,returnthetooltoanyCornwellAuthorizedWarrantyCenter,freightprepaid.Pleaseincludeacopyofyourproofofpurchaseandabriefdescription

oftheproblem.Thetoolwillbeinspectedandifanypartorpartsarefoundtobedefectiveinmaterialorworkmanship,theywillberepairedfreeofcharge,andtherepairedtoolwill

bereturnedtoyoufreightprepaid.

EXCLUSIONS AND LIMITATIONS

THISWARRANTYANDTHE REMEDIESSET FORTHABOVEAREEXCLUSIVEAND IN LIEU OFALL OTHERWARRANTIES, REMEDIESANDCONDITIONS,WHETHER ORALORWRITTEN,

EXPRESSORIMPLIED.CORNWELLSPECIFICALLYDISCLAIMSANYANDALLIMPLIEDWARRANTIES,INCLUDING,TOTHEEXTENTPERMITTEDBYAPPLICABLELAW,ANYWARRANTIES

OFMERCHANTABILITYANDFITNESSFORAPARTICULARPURPOSE.IFCORNWELLCANNOTLAWFULLYDISCLAIMIMPLIEDWARRANTIESUNDERTHISLIMITEDWARRANTY,ALLSUCH

IMPLIEDWARRANTIESARELIMITEDINDURATIONTOTHEDURATIONOFTHISWARRANTY.

INNOEVENTSHALLCORNWELLBELIABLETOTHEPURCHASERORTOTHEUSEROFACORNWELLPRODUCTFORANYSPECIAL,INCIDENTALORCONSEQUENTIALDAMAGESBASED

UPON BREACH OFWARRANTY, BREACH OF CONTRACT, NEGLIGENCE, TORT, ORANY OTHER LEGAL THEORY. SUCH DAMAGES INCLUDE,WITHOUT LIMITATION, EXPENSES, LOST

REVENUES,LOSTSAVINGS,LOSTPROFITS,ORANYOTHERINCIDENTALORCONSEQUENTIALDAMAGESARISINGFROMTHEPURCHASE,USEORINABILITYTOUSETHECORNWELL

PRODUCT.

Somestatesdonotallowtheexclusionorlimitationofincidentalorconsequentialdamagesorexclusionsorlimitationonthedurationofimpliedwarrantiesorconditions,sotheabove

limitationsorexclusionsmaynotapplytoyou.Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightsthatvarybystate.

RepairkitsandreplacementpartsareavailableformanyCornwellproducts,regardlessofwhetherornottheproductisstillcoveredbyawarrantyplan.