Edges

Bullnose and

half bullnose edges

The diamond generators should be in good

condition without any deformities to achieve

the

right profile.

6-motor machine: Sandpaper grits 60, 120,

220, 400, 800, 1500.

8-motor machine: Sandpaper grits 120, 220,

220, 400, 600, 800, 1500, 3000.

Speed*: Approximately 20-25 cm/min.

Pressure: Between 2 and 3 bar.

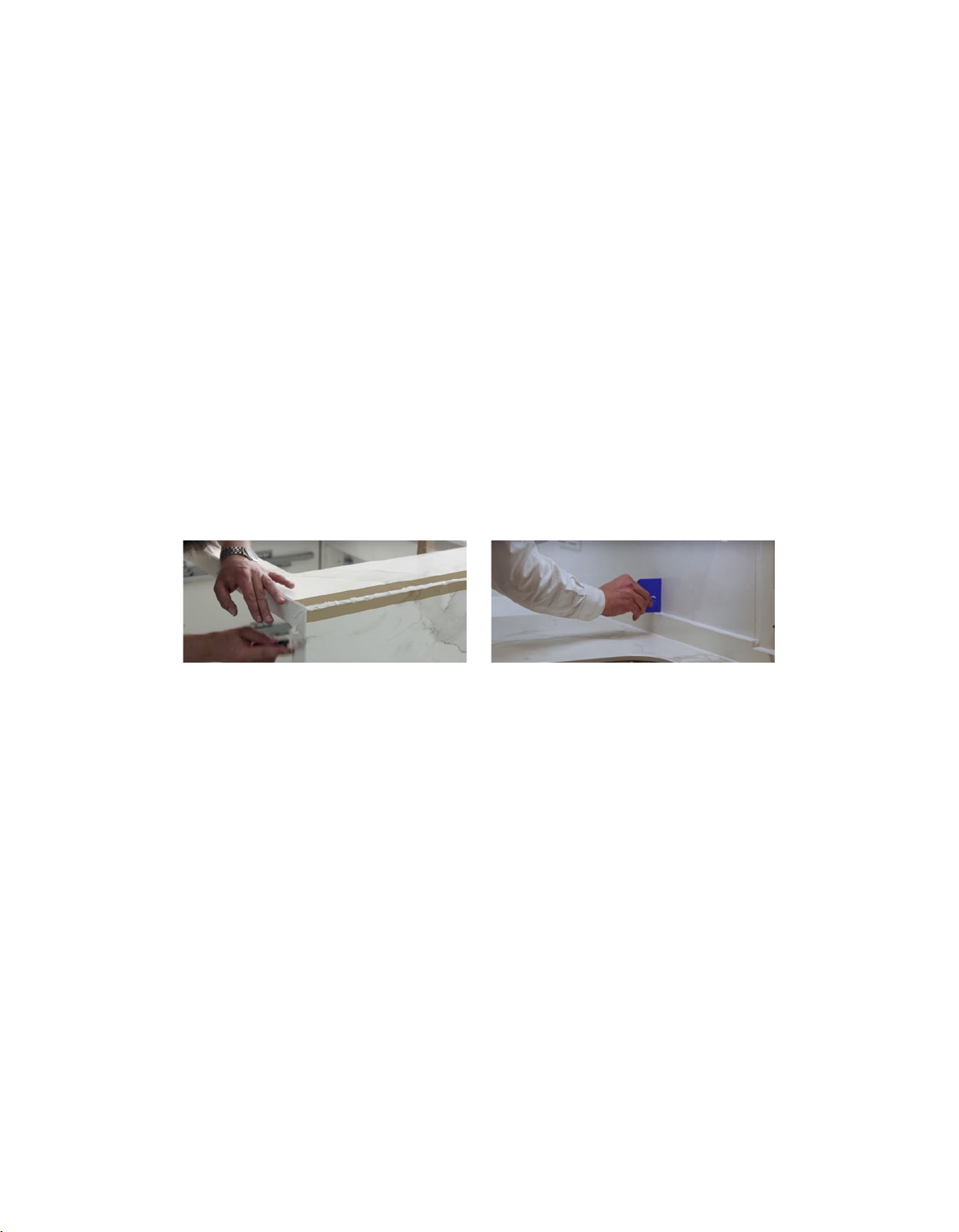

Polishing edges with

manual water polishing

machine

The polished abrasives must be in good

condition. The cutting table and the piece

being worked on should be well secured to

prevent any movement during polishing.

The polishing machine should turn at less than

4000 r.p.m.

The water flow must be high and properly

directed towards the polishing area to keep

the material cool and prevent it from burning.

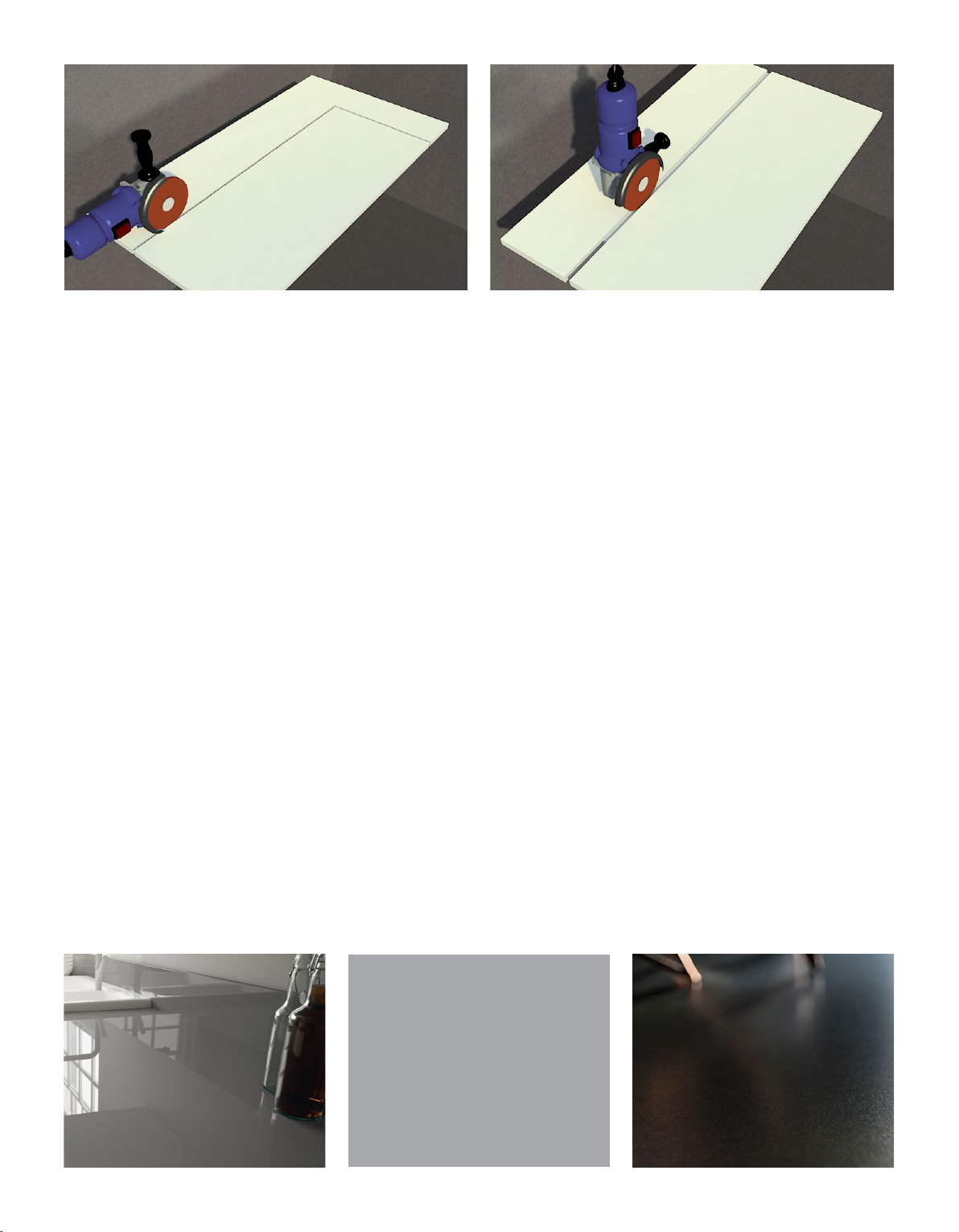

Grind using a diamond disk.

Move the polishing machine gently over the

material without pressing against it. When

polishing, rather than remaining in the same

position on the edge, the machine should be

kept in constant motion.

Use diamond resin sandpapers. Use the

following sequence of grits: 50, 100, 200, 400,

800, 1500, 3000..

Polishing edges with

an automatic edging ma-

chine. Straight edges

6-motor machine: Sandpaper grits 60, 120,

220, 400, 800, 1500.

8-motor machine: Sandpaper grits 60, 120,

220, 400, 600, 800, 1500, 3000.

Speed*: Approximately 50-60 cm/min.

Pressure: Between 2 and 3 bar.

*for dark colours, the speed should be 40-50.

Polishing Suedelook

edges

Use abrasives for SUEDE finishes. These can

be obtained from any store or dealer

authorised by Cosentino.

Polishing by hand

The polishing should be done with water.

Ensure that the manual polishing machine

has a continuous supply of water so that the

product is kept cool.

The sequence of grit size that should be used

is as follows: 36, 36, 46, 46, 60, 120, 220, 400,

600.

For 36, 46, 60, 120 disks the rpm must be

between 1500-2000.

For 220, 400, 600 disks the rpm must be

between 2500-3000.

IMPORTANT: Do not apply pressure as it

breaks the teeth and is dangerous.

Polishing with an

automatic edgingmachine

The pressure of the heads on the edge should

be as low as possible to prevent the teeth on

the special abrasives from breaking.

For such purpose, a back pressure should also

be used to all but cancel out the pressure of

the heads, as shown in the chart.

The trays with the concentric coupling screw

are used for straight edges, whether it is

polished or leather finish.

The trays with and off-centre screw are used

for special edges.

IMPORTANT: Do not apply pressure as it

breaks the teeth and is dangerous.

5