Cee® Apogee™ Developer Manual

Page 2of 15

Contents

1. Apogee™ Developer Introduction...........................................................................................................4

1.1. Confidentiality Statement ................................................................................................................................ 4

1.2. Warranty............................................................................................................................................................... 4

1.3. Returned Materials............................................................................................................................................. 4

1.4. Model and Revisions......................................................................................................................................... 5

1.5. Safety Hazards/Precautions............................................................................................................................ 5

1.6. Overview of Equipment-Specific Hazards................................................................................................... 5

1.7. Electrical............................................................................................................................................................... 5

1.8. Mechanical........................................................................................................................................................... 5

1.9. Chemical............................................................................................................................................................... 6

1.10. Lockout/Tagout Procedures and Information ........................................................................................ 6

1.11. Intended Use of Machine.............................................................................................................................. 6

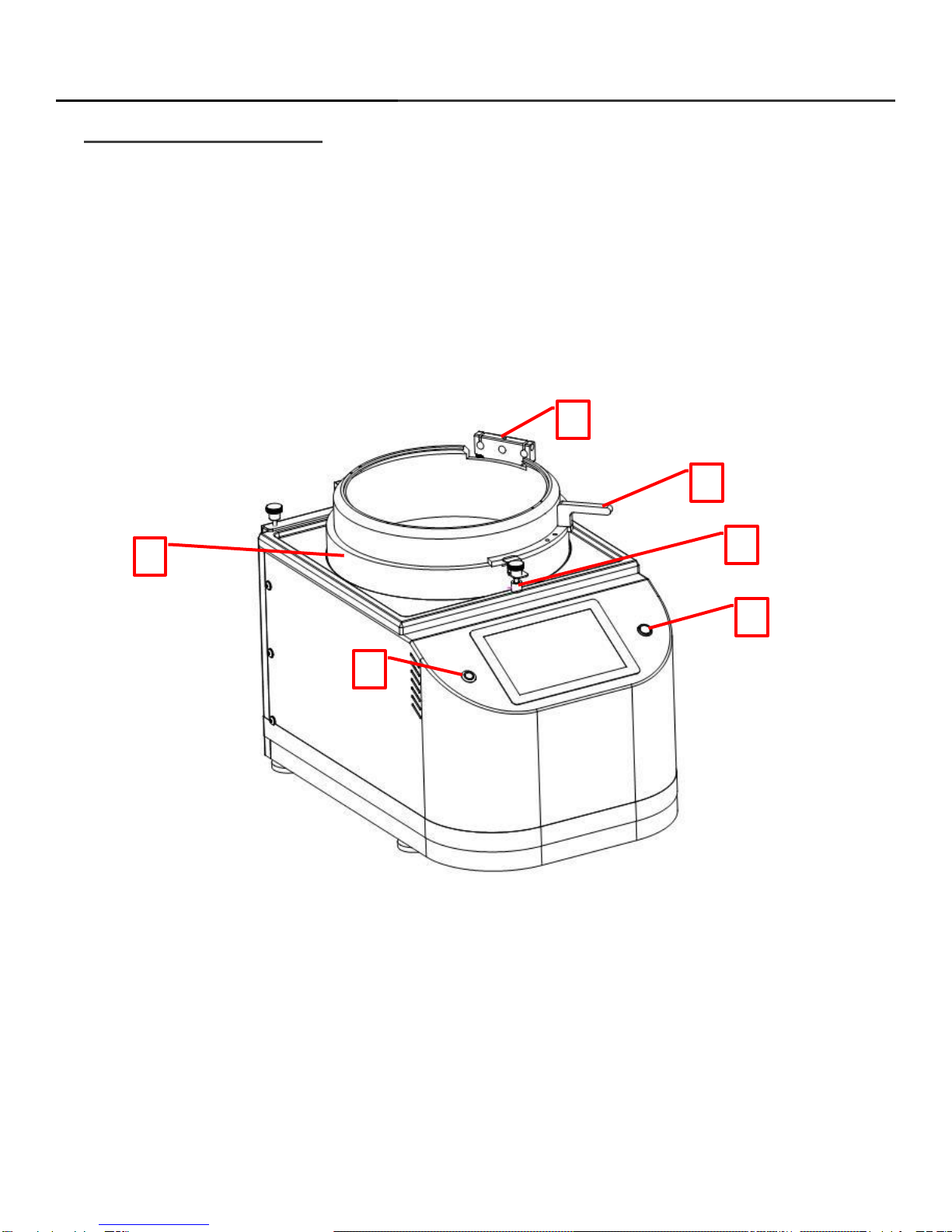

2. Equipment Description ............................................................................................................................7

2.1. Dimensions.......................................................................................................................................................... 8

2.2. Programmability................................................................................................................................................. 8

2.3. Precision............................................................................................................................................................... 8

2.4. Reliability.............................................................................................................................................................. 8

2.5. Bowl Design......................................................................................................................................................... 8

2.6. Utilities.................................................................................................................................................................. 9

3. Installation ................................................................................................................................................9

3.1. Floor Space Requirements.............................................................................................................................. 9

3.2. Facilities Requirements.................................................................................................................................. 10

3.3. Environment...................................................................................................................................................... 11

3.4. Unpacking/Inspection..................................................................................................................................... 11

3.5. System Installation and Setup...................................................................................................................... 11

3.6. Start Up............................................................................................................................................................... 12

4. Developer Use and Operation................................................................................................................13

4.1. Spin Chuck......................................................................................................................................................... 13

4.2. 5- Hole Dispense Nozzle Hub........................................................................................................................ 13

4.3. Lid Adjustment.................................................................................................................................................. 13

5. Preventative Maintenance......................................................................................................................14

5.1. Safety Checks................................................................................................................................................... 14

5.2. Mechanical Checklist...................................................................................................................................... 14

5.3. Utility Checks.................................................................................................................................................... 14