HM Electronics Collamat 2600 Release Note

5

9

9

9

.

5

0

5

-

0

1

C

HM Collamat AG

Bodenmattstrasse 34

CH-4153 Reinach

Switzerland

Phone +41 61 756 28 28

Fax +41 61 756 29 29

www.collamat.ch

Collamat 2600

Technical Handbook

5999.505-01C 12.06.2007 WM22

1Index

1Index..................................................................................................................2

2Safety advices...................................................................................................3

2.1 Important Warnings...........................................................................................3

2.2 Danger Indications ............................................................................................3

2.3 Symbolerklärungen ...........................................................................................4

3Introduction........................................................................................................5

3.1 General informations.........................................................................................5

3.2 The labeler C2600.............................................................................................5

3.2.1 Prevention of accidents.....................................................................................6

3.2.2 Noise suppression.............................................................................................6

3.2.3 Stability..............................................................................................................6

3.3 Assembly parts..................................................................................................7

4Mechanical adjustments....................................................................................8

4.1 Traction unit.......................................................................................................8

4.1.1 Threading the labelweb.....................................................................................8

4.2 Adjustment of rewinder coupling force..............................................................8

4.2.1 Readjustment of paper brake............................................................................9

4.2.2 Longitudinal adjustment on the module rail.......................................................9

4.3 Adjustment of the optical label scanner...........................................................10

5Technical description.......................................................................................11

5.1 Dispenser board..............................................................................................11

5.1.1 Power supply...................................................................................................11

5.1.2 Motordriver......................................................................................................11

5.1.3 Controller.........................................................................................................11

5.2 Signals and connection diagrams ...................................................................12

5.2.1 Inputs...............................................................................................................12

5.2.2 Outputs............................................................................................................13

5.3 Transformer wiring ..........................................................................................14

5.4 Connection of the mains input.........................................................................14

5.5 Connection of the frontpanel ...........................................................................15

5.6 Grounding of the labeler..................................................................................15

5.7 Motor and motorcable .....................................................................................15

6Software..........................................................................................................17

7Trouble shooting..............................................................................................18

7.1 Fuses...............................................................................................................18

8Peripheral units and sensors...........................................................................19

8.1 Optical label scanner.......................................................................................19

8.2 Goods scanner NPN .......................................................................................20

8.2.1 Connecting the goods scanner........................................................................20

9Cabling and setting up.....................................................................................21

9.1 Cabling ............................................................................................................21

9.2 Setting up ........................................................................................................21

10 Version numbers .............................................................................................22

11 Glossary and terms .........................................................................................23

11.1 Short cuts........................................................................................................23

11.2 Signals.............................................................................................................23

11.3 Terms ..............................................................................................................23

12 Technical Data ................................................................................................24

12.1 Dimensions......................................................................................................24

13 Troubleshooting...............................................................................................27

13.1 Troubleshooting Collamat 2600 ......................................................................27

5999.505-01C 12.06.2007 WM 23

2Safety advices

2.1 Important Warnings

Before installing and operating the Collamat 2600 read following

safety instructions:

•The labeler C2600 is exclusively determinated for labelling goods.

•The installation of a Collamat 2600 has to be done by a trained specialist.

For this you have to consider the national specific regulations of

•prevention of accidents

•mechanical stability

•construction of electrical and mechanical systems

•noise suppression

•Take notice to the technical data of the Collamat 2600. Especially the en-

vironment conditions must be observed.

•The operation of the Collamat 2600 must be done by trained personnel.

•In case of non-authorized modification guarantee will fall.

•Before connecting non-standard products ask your competent technical

supporter.

2.2 Danger Indications

•The safety symbols and danger advices on the Collamat 2600 and in this

manual must strictly be observed.

•Before connecting or disconnecting the labeler to or from the main, it must

be switched off.

•The labeler C2600 may only be opened by authorized personnel.

•Before opening the labeler C2600, it must be separated from the main po-

wer.

•It exists danger of pinching hairs, jewelry, ties, clothes etc. into the traction

unit

•It exists danger of injury by cutting fingers in the area of the paper web.

•It exists danger of injury in the area of the dancer of the unwinder of the

Collamat 2600.

•It exists danger of injury in the area of the paper stockcontroller of theCol-

lamat 2600.

•For operation on the Collamat 2600 the operating personnel must keep to

a safely place to prevent injury from the products being labeled.

5999.505-01C 12.06.2007 WM24

2.3 Symbolerklärungen

ATTENTION

Indicates danger of damaging the Collamat 2600 or other sys-

tem components, with a potential consequential danger of in-

juries.

DANGER

Indicates an immediate hazard for persons.

DANGER

Shock hazard due to high voltage at component.

DANGER

Hazard due to high temperature component.

ATTENTION

ESD warning (Electro Static Discharge). The PC boards or

component may only be touched in an electrostatically pro-

tected environment.

NOTE

Important or additional information to Collamat 2600 or to the

documentation.

Issue 12.6.2007

Technical modifications reserved.

Collamat is a registered trademark of HM Collamat AG

© Copyright 2004 by HM Collamat AG, CH-4147 Aesch

All rights reserved.

This operating manual may neither in whole or in part be reproduced, dupli-

cated, or copied; electronically or otherwise, without express written consent

of HM Collamat AG.

i

5999.505-01C 12.06.2007 WM 25

3Introduction

3.1 General informations

This technical handbook describes the construction and the function of the

Collamat 2600. In addition to the operating instructions, it contains the neces-

sary tips and adjustments to get optimum use of the Collamat 2600. The de-

scriptions of each electrical or mechanical device also helps for quick error

analysis and error elimination.

We recommend you to replace the complete electronic boards. Return it to

HM Collamat AG or to its representative for repair. You can then feel sure,

that the high quality standard of the Collamat 2600 can also be guaranteed

after repair.

3.2 The labeler C2600

Special characteristics of the Collamat 2600:

•resistant to wear, no clutch/brake-system

•robust, stable

•easy installation and operation due to the modular construction

•quick change-over to other labelling tasks

•high performance

•high reliability

•latest SMD-technology

•high precision 2-phase steppermotor

The traction unit as well as the other peripheral assemblies are mounted on

a modular rail. The modular rail is equipped with an integrated scale.

The operating elements for dispensing speed, predispensing, optical label

scanner, as well as the mains switch are placed right on the body of the trac-

tion unit itself. The feedroller of the traction unit is provided with a special

coating for permanent nonslip torque transmission onto the paperweb. The

rewinding force of the rewinder as well as the braking power of the paper

brake are adjustable at the traction unit from the outside.

The installation of the Collamat 2600 must be done by trained personnel. For

this you have to consider the national specific regulations of:

•prevention of accidents

•noise suppression

•mechanical stability

•construction of electrical and mechanical systems

5999.505-01C 12.06.2007 WM26

3.2.1 Prevention of accidents

While installing and connecting the Collamat 2600 take care that the signal

cablesandpower cables can'tbecomeobstacles. The cablesmustbe placed

and installed according to the national safety requirements. Take care that

the signal cables are not placed beneath power cables.

The power switch and the controll elements must easily be accessible.

3.2.2 Noise suppression

The dispenser C2600 is shielded according to the CE directives. Only cables

which are certificated by HM Collamat AG may be used for connecting the

dispenser to the peripheral units and the mains power.

3.2.3 Stability

If the Collamat 2600 is used on a movable stand, this stand must be capable

to be tilt 10° in each direction. See also following Figure 1:

Figure 1: Stability of the stand

10° 10°

5999.505-01C 12.06.2007 WM 27

3.3 Assembly parts

The assembly parts are mounted and placed on a modular rail. Following fig-

ure 2 shows these assembly parts with their names on the modular rail:

Legend:

1: Unwinder dancer

2: Unwinder

3: Traction unit

4: Papierbremse

5: Modular rail

6: Support

7: Adapter

Figure 2: Assembly parts

123 4 567

5999.505-01C 12.06.2007 WM28

4Mechanical adjustments

4.1 Traction unit

4.1.1 Threading the labelweb

Threadthelabelweb asshown infigure3 upto thedispensingedge anddraw

it out by approx. 1 m. Detach the labels from the paperweb at the drawn-out

web. Then open the pinchroller by turning the knob (1), place the paperweb

over the dispensing edge and finish threading the paperweb as shown in fig-

ure 3. Close the pinchroller. Adjust the side guides of the paperweb well,

leaving 0.5 mm free space to the paperweb's edge.

4.2 Adjustment of rewinder coupling force

The coupling force of the rewinder is factory-set. Proceed as follows if out of

adjustment: Detach winding spindle (1) after unscrewing the M5-bolt (3).

Screw M8-bolt (2) accordingly:

•in = harder coupling

•out = softer coupling

Figure 3: Threading

1

Figure 4: Rewinder coupling

3

2

1

5999.505-01C 12.06.2007 WM 29

4.2.1 Readjustment of paper brake

The braking force is factory-set to an optimum value. Should it, however, be

unadjusted, readjust it with the M3-bolt (1) in the web-end controlbox of the

traction unit, from the outside.

•Screw in bolt = higher braking force

•Unscrew bolt = lower braking force

4.2.2 Longitudinal adjustment on the module rail

Unscrew 4 bolts with special tool (wrench for socket head cap screws 5 mm)

one half turn.

Move device, observing scale on module rail. Then tighten bolts equally..

1

Figure 5: Paperbrake

Figure 6: Longitudinal adjustment

5999.505-01C 12.06.2007 WM210

4.3 Adjustment of the optical label scanner

Proceeding of the adjustment of the optical label scanner:

Switch on the Collamat 2600. Set the label scanner potentiometer to zero.

Pull the labelweb so that the gap is located below the marking 1 of the scan-

ner. Turn the potentiometer until the red LED on the scanner goes off. Con-

tinue pulling the labelweb until a label is located below the scanner. Continue

turning the potentiometer until the LED switches off again.

Theoptimum settingisatthecenter positionofthetwopotentiometersettings

witch turned the LED off.

Remark:

If the setting of the optical label scanner is faulty, the gap between the

labels will not be detected. After the triggering of a labelling operation,

the labeler will stop after approx. 0.75 m of the labelweb.

For transparent labels, please use the mechanical label scanner.

Figure 7: Adjustment of the optical label scanner

Gap

LED

1

i

5999.505-01C 12.06.2007 WM 211

5Technical description

5.1 Dispenser board

All the electronic devices including power transformer, except of the main

switch with indicator lamp, are located on a printed board. The dimensions of

the board are approximately 215 x 234 mm. Figure 8 shows the board with

all the connectors and terminals.

The description is divided into power supply, motordriver, controller and firm-

ware.

5.1.1 Power supply

The power supply unit generates the two regulated voltages +12 V/1A and +

5 V/0.5A for the logic, as well as an unregulated DC voltage of approx. 32 V/

3.5 A for the steppermotor. The 5V stabilization is done by linear voltage reg-

ulators. The 12V is stabilized by a switched mode regulator.

5.1.2 Motordriver

Thedriverboard consists of2H-bridge circuits todrivethe two motorphases.

The phase current is 3 A while running, and 0.7 A when stopped. To control

the current, a chopper circuit with 23 kHz chopper-frequency is used.

Dependent on the dispensing speed the processor generates a sinusoidal

current.

In the case of overheating, short-circuit or malfunction the motordriver is swit-

ched off. In this case the labeler must be switched off and on again. If over-

heated wait until the labeler is cooled down to ambient temperature. After a

short circuit replace the appropriate fuses.

5.1.3 Controller

A single chip micro-controller manages the functions of the labelling process.

•All the inputs are pulled up to +12V with 2.2 K and are equipped with a low-

pass filter.

•The potentiometers for speed and predispensing are scanned immediate-

ly before performing a labeling cycle.

•The control current of the label scanner is generated by a current source

controlled by the thirt potentiometer.

5999.505-01C 12.06.2007 WM212

5.2 Signals and connection diagrams

All in- and outputs are equipped with filter elements to prevent electromag-

netic interference. These components also prevent interference caused by

electrostatic discharge. The interference can lead to malfunction of the Col-

lamat 2600. Anyway, installing the Collamat 2600 you have to consider the

rules concerning RMI and ESD to prevent these interferences. See also

chapter Cabling.

5.2.1 Inputs

The inputs are used to connect peripheral units and sensors. The inputs are

activated while they are pulled to GND (0 Volt). The peripheral units from HM

Collamat AG have NPN-outputs to 0 Volt. Figure 9 shows the schematic dia-

gram of the inputs:

Figure 8: Dispenser board

5999.505-01C 12.06.2007 WM 213

On: >4mA (or < 2 V)

Off: 0mA (or > 8 V)

Vmax: 24 V

Aninput isthen active,when acurrent ofminimum 2mAis pulledto GND.The

following inputs are available:

•GSC1 Goods Scanner

•LSC Label Scanner

5.2.2 Outputs

The Collamat 2600 has a current source output for the IR-transmitter of the

labelscanner. Figure 10 shows the shematic diagram of the currentsourse.

Figure 9: Signal inputs

Figure 10: TCY-current source

5999.505-01C 12.06.2007 WM214

5.3 Transformer wiring

ATTENTION:

Before opening the Collamat 2600 it must be complettely disconnected

from mains.

The secondary side of the transformer is connected to the terminals X10 ac-

cording to the table below:

The primary side of the transformer is connected to the terminals X6 accord-

ing to the table below:

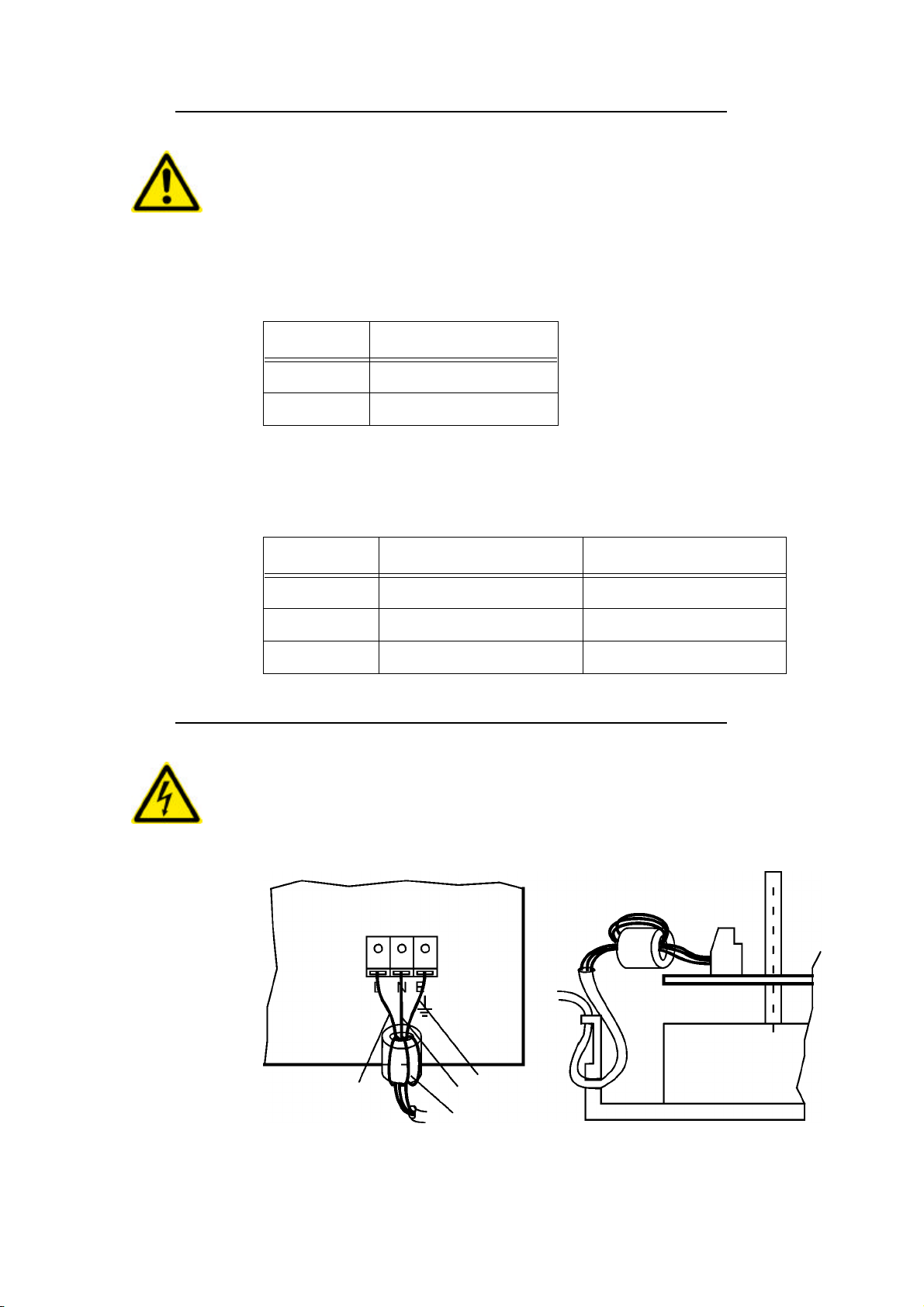

5.4 Connection of the mains input

ATTENTION:

High voltage. Mains voltage

The powercord must be connected to the terminal X1. To prevent interfe-

rences it must be looped through a ferrite-filter as shown in Figure 10:

Table 1: Transformer connection secondary side

Terminal Colour

X10.1 Green

X10.2 Red

Table 2: Trafoanschluss Primärzeitig

Terminal Colour for 220V Colour for 110V

X6.1 Orange Orange + Brown

X6.2 Red + Brown nc

X6.3 Black Red + Black

Figure 11: Mains connection

Brown Yellow/Green

Blue

Ferrit-Filter

IN

X1

5999.505-01C 12.06.2007 WM 215

5.5 Connection of the frontpanel

The frontpanel must be connected as shown in Figure 12:

5.6 Grounding of the labeler

The grounding of the module rail and of the adapter must be done to terminal

X2. See also Figure 12.

5.7 Motor and motorcable

Attention:

•The motor never must be dismantled !

•Steppermotor heats up during operation !

•When connecting or disconnecting the motor, the labeler must be

switched off !

•While working on the motor, the labeler must be disconnected from

mains!

Figure 12: Frontpanel connection

Brown

Blue

Brown/White

Ground

X2

X4 X5

X3

F1

5999.505-01C 12.06.2007 WM216

The motor is connected inside of the labeler. The motorcable is lead through

the hole in the middle part of the board. See Figure 13:

The motorwires are connected to the terminal X12. The mode connecting the

orange and black wire determines the turning direction of the stepping motor.

See also table below:

Table 3: Motor connection

Terminal Left Right

X12.1 Black Green Orange Black

X12.2 Orange Black Black Green

X12.3 Red Blue Red Blue

X12.4 Yellow Red Yellow Red

Figure 13: Motor connection

X12

1 2 3 4

Red / Blue

Yellow / Red

5999.505-01C 12.06.2007 WM 217

6Software

After turning on the labeler, the input signals are scanned to start a labeling

cycle.

The dispensing of a label is triggered by the negative edge of GSC (Goods

scanner input). The stop of the labelling is triggered by the detection of the

gap (LSC) and performing the remaining steps for the predispensing.

The timing diagram of the signals is shown in Figure 14:

1. Length of the predispensing

If the signal FEED is active the motor is turning. The FEED signal has no

electrical tabs on the Collamat 2600 terminals.

If the predispensing is increased, it is executed immediately. If it is reduced,

it is executed after dispensing the next label.

To generate the holding torque, the motor is powered all the time.

If, for any reason, no negative edge is detected on the LSC-input, the label-

web is automatically stopped after approximately 0.75 meters.

The stepper motor is driven by a sinusoidal corrent figure.

The minimum speed is 3 m/min. The maximum speed is 15 m/min.

Figure 14: Timediagram of the signals GSC, LSC and FEED

Signal

GSC

LSC

FEED

1

t

5999.505-01C 12.06.2007 WM218

7Trouble shooting

7.1 Fuses

The Collamat 2600 contains three fuses:

To exchange the fuses, the cover of the Collamat 2600 must be removed. If

the fuse of the main voltage is blown, the indicator lamp of the power switch

is not illuminated when the Collamat 2600 is switched on.

ATTENTION:

If the dispenser board is defective, it must be exchanged. Any repairs

ormodifications notmadeby HMCollamat AGwillexpire theguarantee.

Table 4: Sicherungen

Fuse Voltage Value Part. No.

F1 110V:

230V: Mains voltage 4AT; 5*20mm

2AT; 5*20mm 74030800

74030341

F10 Motordriver 3.15T; 5*20mm 74031216

F11 Logic 12 V, 5V 1AT; 5*20mm 74030755

5999.505-01C 12.06.2007 WM 219

8Peripheral units and sensors

8.1 Optical label scanner

The colours ar assigned as follows:

Table 5: Colurs of the LSC & TCY wires

Signal Colour

+12V (LSC) Green

LSC White

GND Brown

+12V (TCY) Green

TCY Brown

Figure 15: Optical label scanner

Labelscanner

+12V

LSC

GND

5

9

1

Transparency

+12V

TCY

5

1

5999.505-01C 12.06.2007 WM220

8.2 Goods scanner NPN

8.2.1 Connecting the goods scanner

The goods scanners is connected to the GSC1connector. Figure 17 shows

the connection of the standard HM Collamat AG IR goods scanner:

Figure 18 shows the connection of a NPN-scanner:

Figure 16: NPN-Reflective scanner

Goodscanner

+12V

GSC

GND

NPN

Figure 17: Connection of the CS IR goods scanner

GND

GSC+

12V

GND

LSC

12V

TCY

12V

bn

gn

bn

ws

gb

gn

GND

+12V

GND

GSC1

+12V

IR

Figure 18: Connection of a NPN-scanner

GND

GSC+

12V

GND

LSC

12V

TCY

12V

GND

GSC1

+12V

NPN

Table of contents