COTSWOLD CLUSTER FLUSH

Milking Cluster Disinfection System

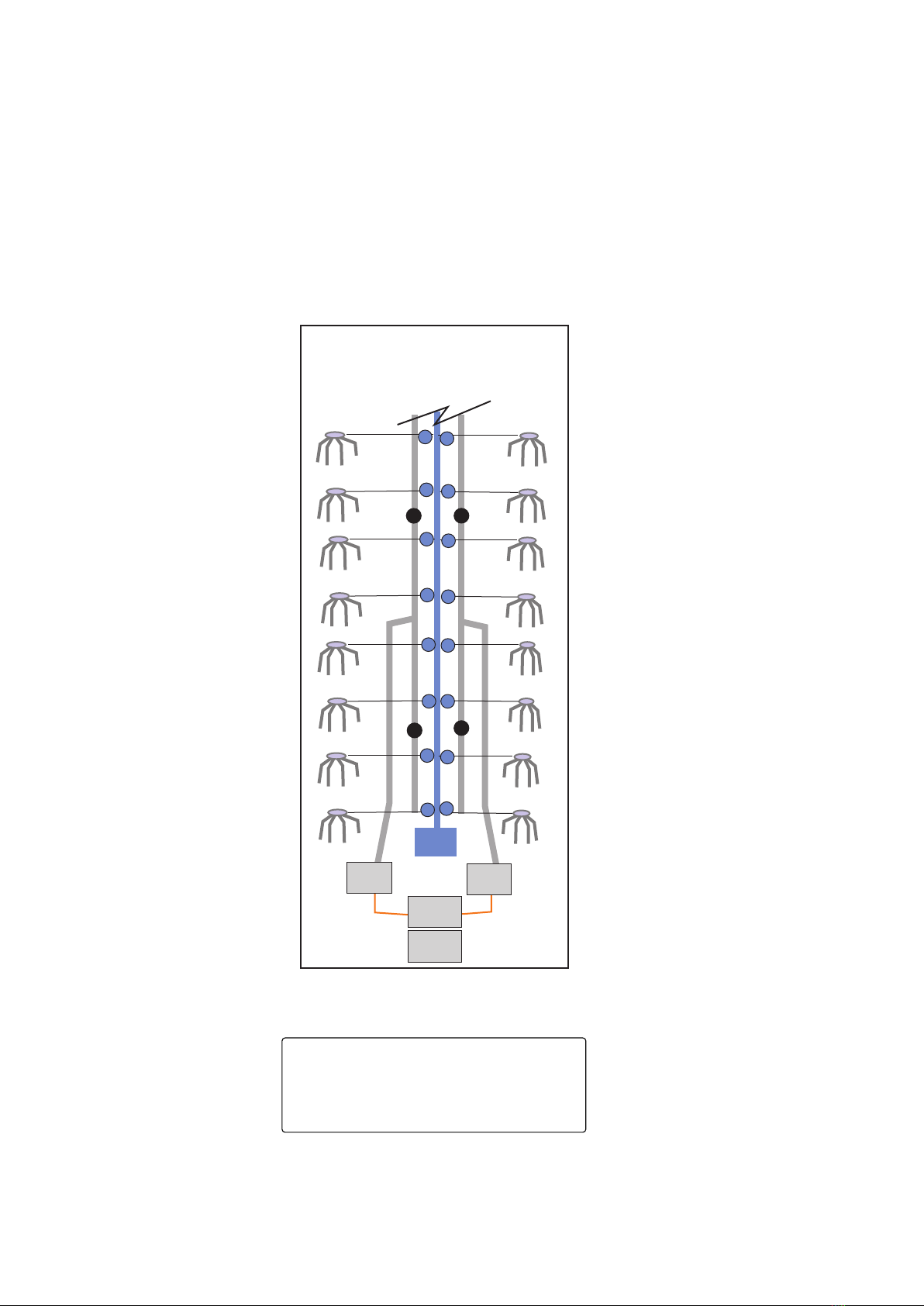

FOR SWING OVER PARLOURS

Model 220

PRODUCT MANUFACTURING, SERVICING & MAINTENANCE OVERVIEW

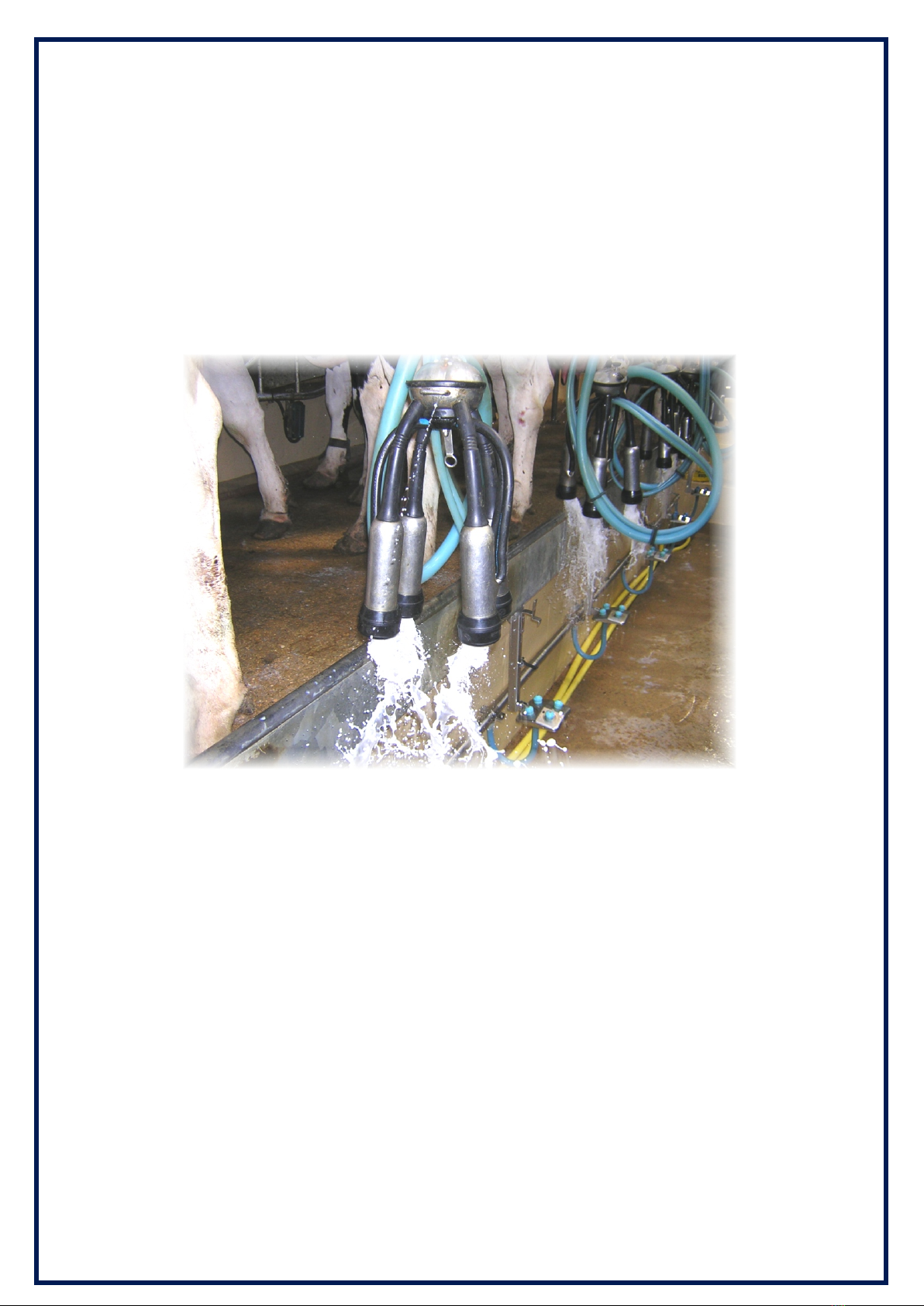

The Cotswold Cluster Flush is a system for the effective removal of infectious

material left in the milking cluster after a cow has been milked, so that the cluster

is disinfected before it is used to milk another cow.

The system mixes a small amount of recommended disinfectant with a pre-

determined amount of water, and automatically “flushes” each milking cluster with

this mixture. This process is repeated after every cow is milked.

Using the Cluster Flush System leads to a substantial reduction in the risk of

cross-infection between cows in the dairy.

SERVICES

The system is mains-powered (230v 50/60hz 1amp). At the point of use the

operating voltage is reduced to 24v dc.

The system requires a ready supply of fresh clean water and a clean compressed-

air supply (at 2 bar).

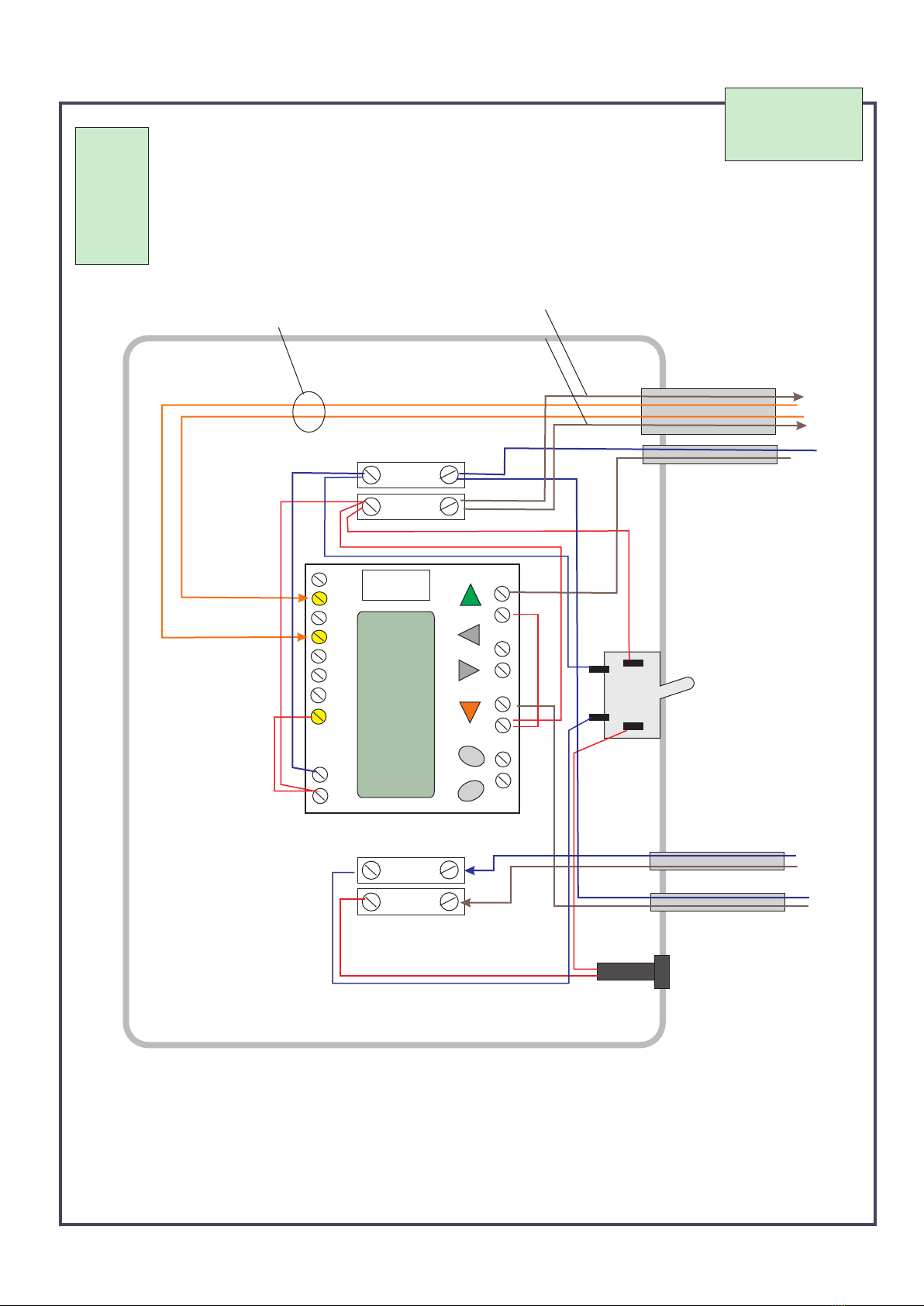

WIRING:

Connect the Power Supply Unit (PSU) to the mains via a double-pole isolation

switch, which should be visible and within easy reach of system operators.

Wiring from the power supply to each control box should be SELV, using a suitable

type of wire like H03VVF with a CSA of at least 0.75mm2.

All controllers and the power supply unit must be suitably earthed.

All connector tags and terminals will be zinc plated.

This equipment is rated for OV (over-voltage) Category 2 supplies.

PRESSURE VESSEL SPECIFICATION AND USAGE

The pressure cylinder is SEP-rated category-1 at its 2 bar mandatory operating

pressure. Its maximum safe pressure rating is 6 bar.

ENVIRONMENTAL CONDITIONS:

The system can be installed in milking parlours anywhere on the planet. Do not

use in the open, in direct sunlight or where pipework could be subject to freezing.

The protection offered by this product may be impaired or lost if installation and

maintenance is not carried out in line with the instructions in this manual.

LABELING

All labels used in this product comply with the CE Water and Hexane Rub Test. 3