INSTALLATION NOTES

ORDER OF INSTALLATION

For ease of installation we recommend the

following installation sequence:-

1/ Header Tank(s)

2/ Water / Plumbing

3/ Set Up Water Cylinders

4/ Install Airlines

5/ Controllers and Electrical

WATER / CHEMICAL

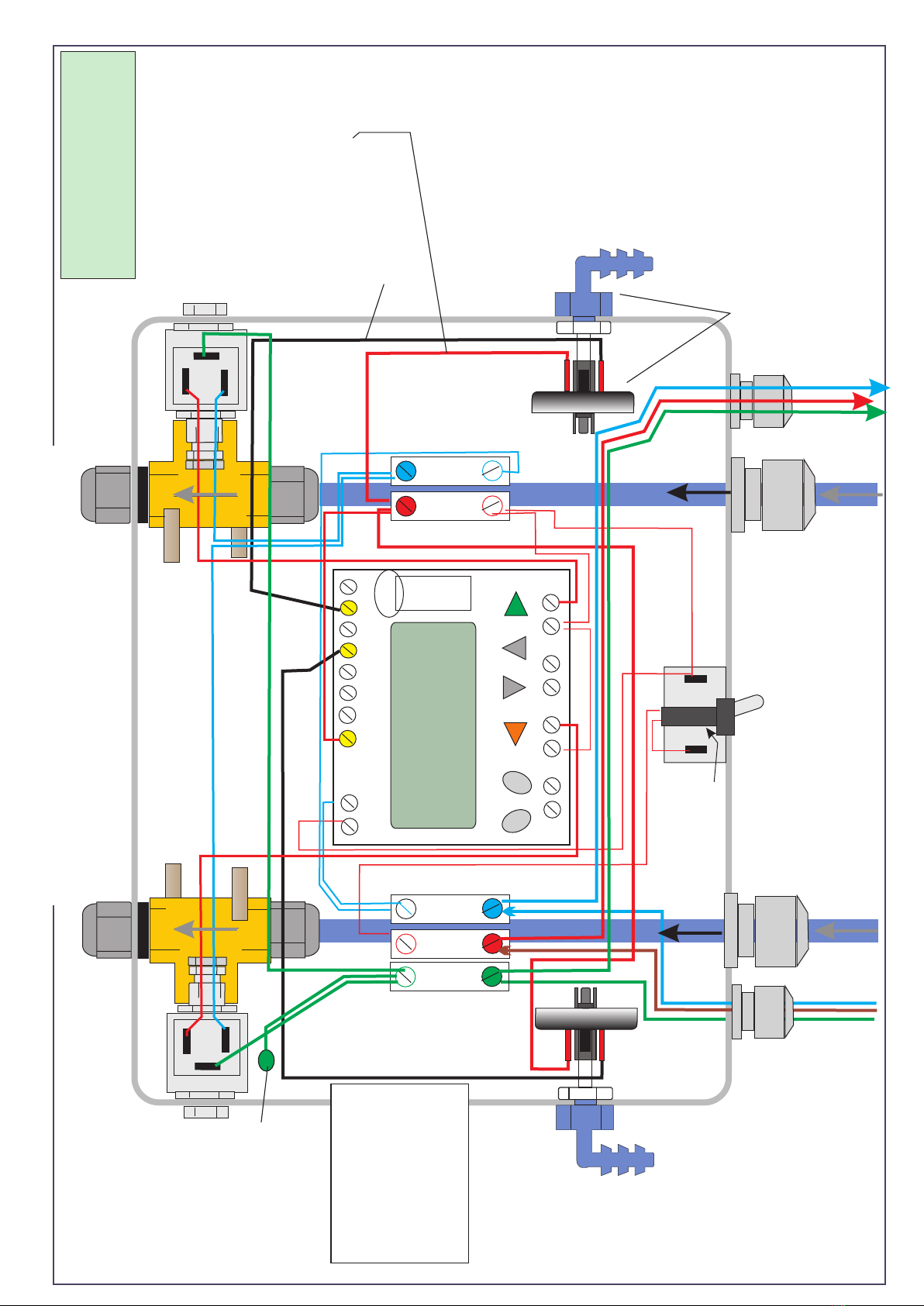

Site the Header Tank at the same level as the

cylinders. Ensure that the water level in the

cylinders is set 50mm (2 inches) below the top

of the stainless tube, (see drawing opposite).

Run 2 inch (50mm) water tube from header tank

along the centre of the parlour, connecting to

every cylinder using tees, taps and 10x16mm

i/d tube. Terminate this tube with a reversed

(upside-down) tee/tap so that it can be used as

a drain point if required.

Chemical Dosing

We can supply Dosatron high accuracy dosing

units if required. When dealing with chemicals,

do take all recommended precautions. Before

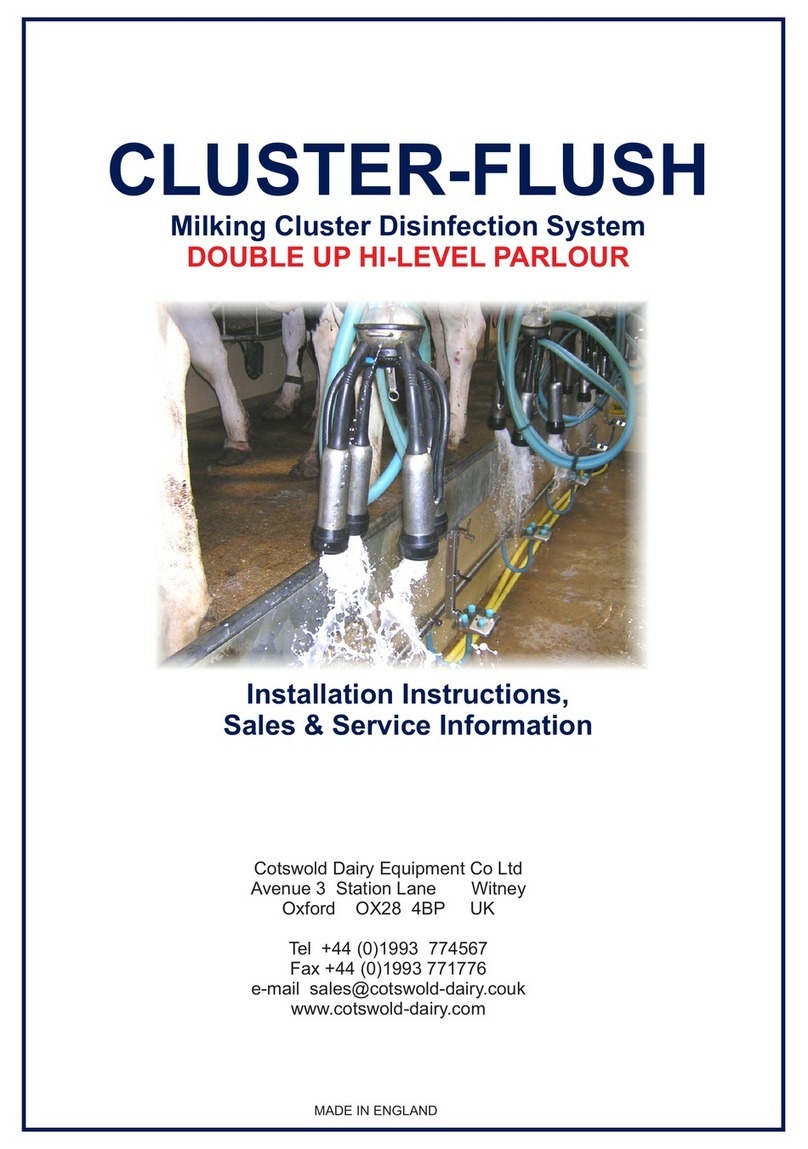

commissioning the system, ensure all unions

are tight and the clusters hang correctly

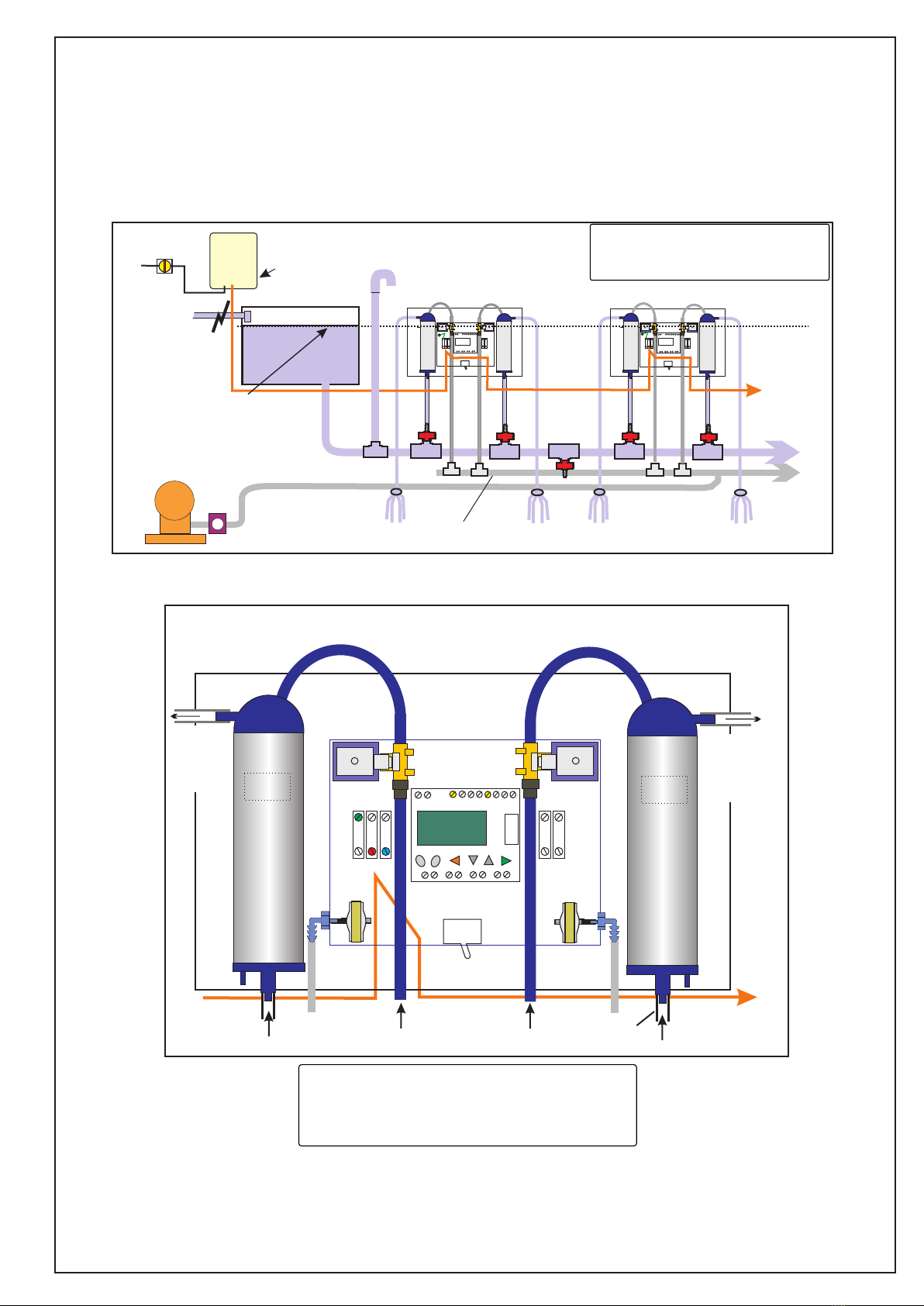

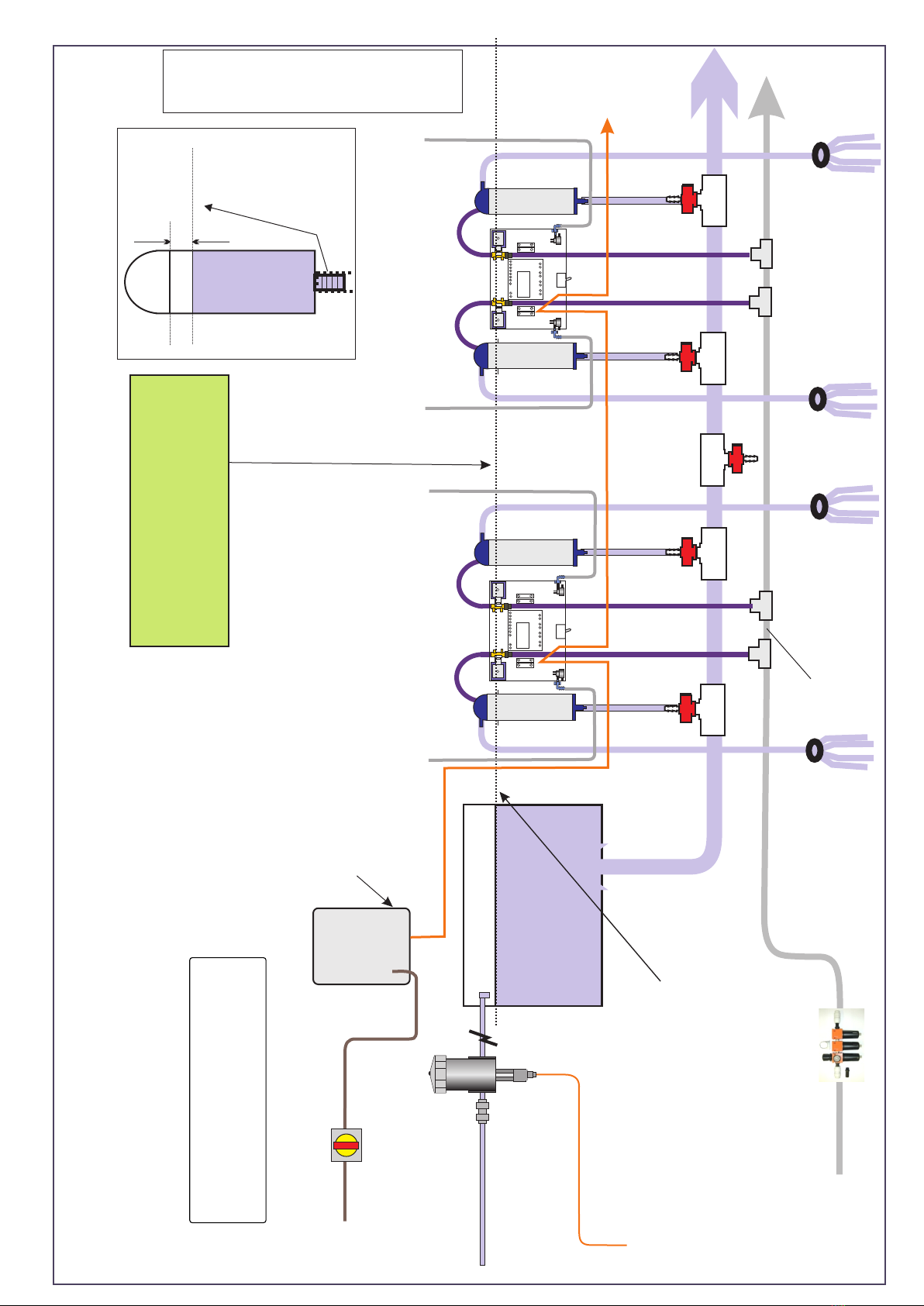

Schematic Top View

disposition of system components for

swing-over parlour

HEADER

TANK

COMPRESSOR

MAINS ISOLATOR

SWITCH

PSU

AIR 24v DC WATER

CONTROLLERS

CONTROLLERS

CONTROLLERS

AIR 2 - 3 bar, (pressure reducer may be

required)

Use 22mm Flexible Tubing between the

compressor (clean air filters should be fitted)

and the first 22x22x10mm tee located adjacent

to the first controller. Continue to following

controllers using rigid tubing. Terminate the air

line in a blanking cap.

Anti-Syphon Valves

fit one valve either side of the Tee connection of air line, at the mid-point of each half (see schematics)

Pressure Reducer

Cotswold can supply a suitable pressure reducing valve if required.

ELECTRICAL

Install Power Supply Unit (PSU) in a safe dry location adjacent to the dairy, run 24v supply to first controller,

and then daisy-chain the supply from controller to controller.

Each controller controls two milking points simultaneously.

Arrange a conveniently located switch to turn off the system when not in use.

Always switch off system when washing-down the parlour

CONNECTION TO MILK LINE

Cut into the milk line and fit the “Y” piece moulding using 13mm pvc tubing connecting to upper

horizontal outlet of stainless steel pressure cylinder.

= Anti Syphon

Valve

AIR

WATER

24v

6