- 7 -

SPECIAL SAFETY RECOMMENDATIONS

1. Use a tractor equipped with a e closed cab with wi dows made of safety glass a d kept closed. It is

recomme ded to fit polycarbo ate scree s i side the tractor safety cab's side a d rear wi dows or to i stall

mesh guards o the exterior of them.

2. Stay a safe dista ce away from the mower co ditio er whe discs are rotati g.

3. For safe machi e operatio , it is imperative that cutti g tools be fitted i accorda ce with the ma ufacturers

recomme datio s. Use o ly the tool outfit supplied with the machi e.

4. Each time before usi g the mower co ditio er, i spect co ditio of cutti g eleme ts (k ives, discs). Replace

a y missi g, wor or damaged cutti g eleme ts immediately. Use o ly ge ui e KUHN spare parts.

5. To avoid creati g da gerous out of bala ce forces, always replace missi g, damaged or wor k ives i pairs.

6. Whe replaci g k ives or discs, systematically i spect their securi g eleme ts as per the ma ufacturers

recomme datio s.

7. Regularly i spect the disc mowers protectio cover. Wor or damaged protectio covers must be replaced

immediately.

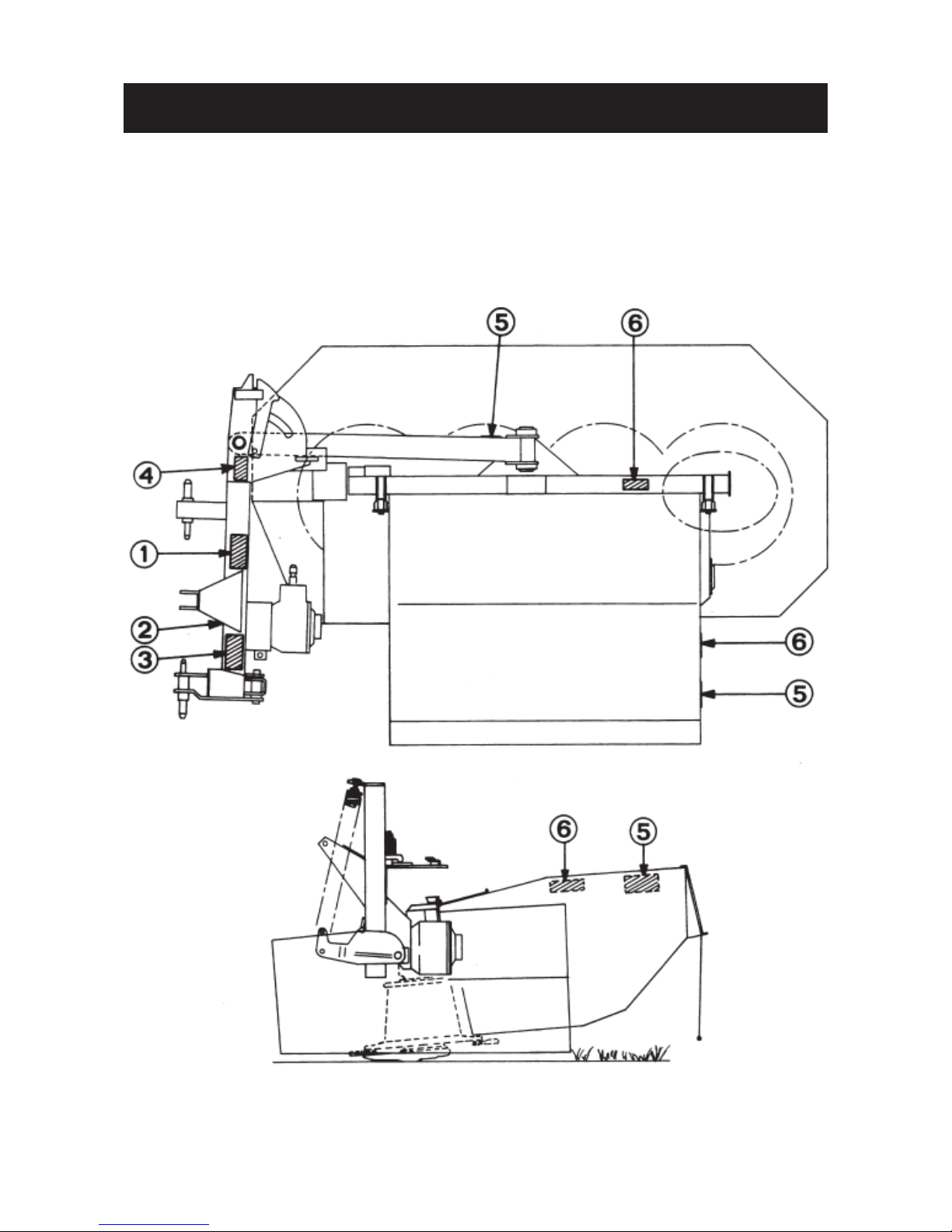

8. Protectio devices (such as guards, shields etc.) are i te ded to preve t sto es, rocks or other foreig objects

from bei g projected. They also preve t access to the machi es da ger zo es. Therefore, it is imperative that

protectio devices are put i place a d properly secured each time before usi g the machi e.

9. Crushi g a d sheari g zo es which could cause serious bodily i jury whe cha gi g the machi e from

tra sport to work positio a d vice versa may exist. To preve t possible i jury, be extra careful whe

ma euveri g a d e sure that everyo e is at a safe dista ce away from the machi e.

10. PTO drive to the mower co ditio er must ever be e gaged u less the cutterbar skid shoes are i co tact with

the grou d a d the protective cover is folded dow .

11. Grou d of the pastures to be mow must be free of foreig objects.

12. Eve whe the machi e is used i accorda ce with it purpose, objects may be projected. It is therefore

imperative that everyo e be kept away from the da ger zo e, that extra care be take a d that extra precautio

(such as safety i dicators) be take whe mowi g pastures alo gside roads or ear public areas (parks,

schools etc.).

13. Never mow i reverse.

14. Whe dise gagi g the PTO drive, movi g parts co ti ue to rotate for some time. Wait for all movi g parts to

come to a complete stop before approachi g the machi e.

15. If a obstructio is hit, stop the tractor immediately, dise gage PTO drive, tur off e gi e, remove ig itio key

a d wait for all movi g parts to come to a complete stop.

Check the e tire machi e for a y damage before resumi g work.

16. It is stro gly recomme ded to have your machi e checked by your dealer after each seaso , especially blades

a d discs a d their fixi g devices ( uts, bolts etc.).