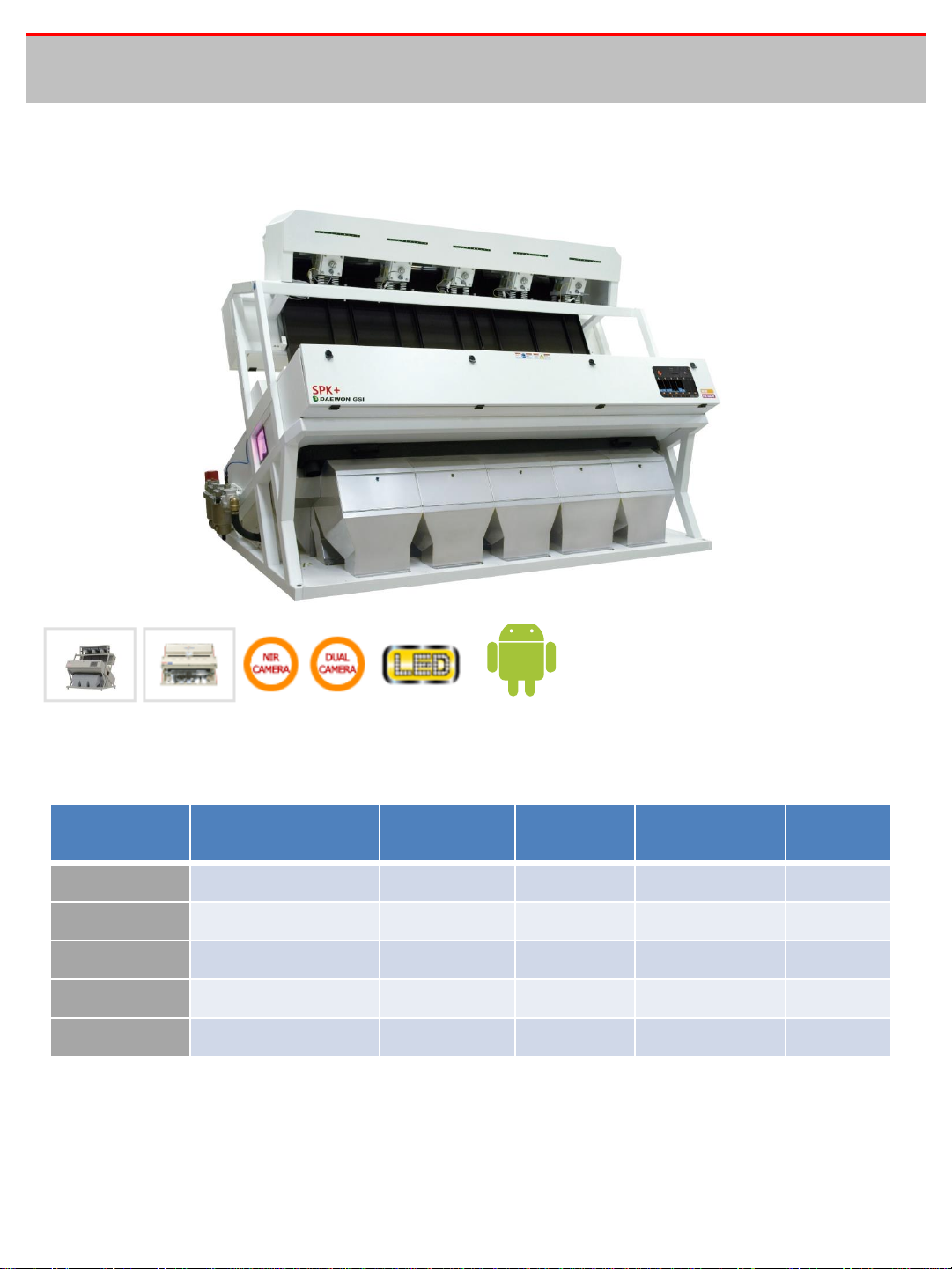

SPK+ | Before the installation

It is necessary to have full knowledge of the installation requirement.

It is only possible to deal with the troubles one may experience during the installation when

considered below. Please fully understand below before inspection.

Installation condition

Location

The surface must be horizontal.

The system shouldn’t be interfered from vibration by surrounding machines or equipments when

installed in a plant or structure.

Vibration may causes in malfunction of the image processing unit.

Finish all the welding before the installation. The residues from welding may cause deformation of the

system structure.

Environment

Operation temperature is between 0℃ to 45 ℃.

The location must be cool and dust free

Lighting

Installing location shouldn’t have great difference of the intensity of the illumination

Keep the system away from direct light from sun or fluorescent light.

Make sure that the system is not under direct sun light during the day time.

Use a curtain if it is necessary.

Clearance

Please make sure that there is enough clearance for A/S or repairing.

The front and back of the machine should have enough clearance for repairing or maintenance.

Plan the cable route properly for the maintenance of the feed hopper and the vibrator connected to

the feeder.

The front of the machine needs clearance for the discharge of sorted material or changing chutes.

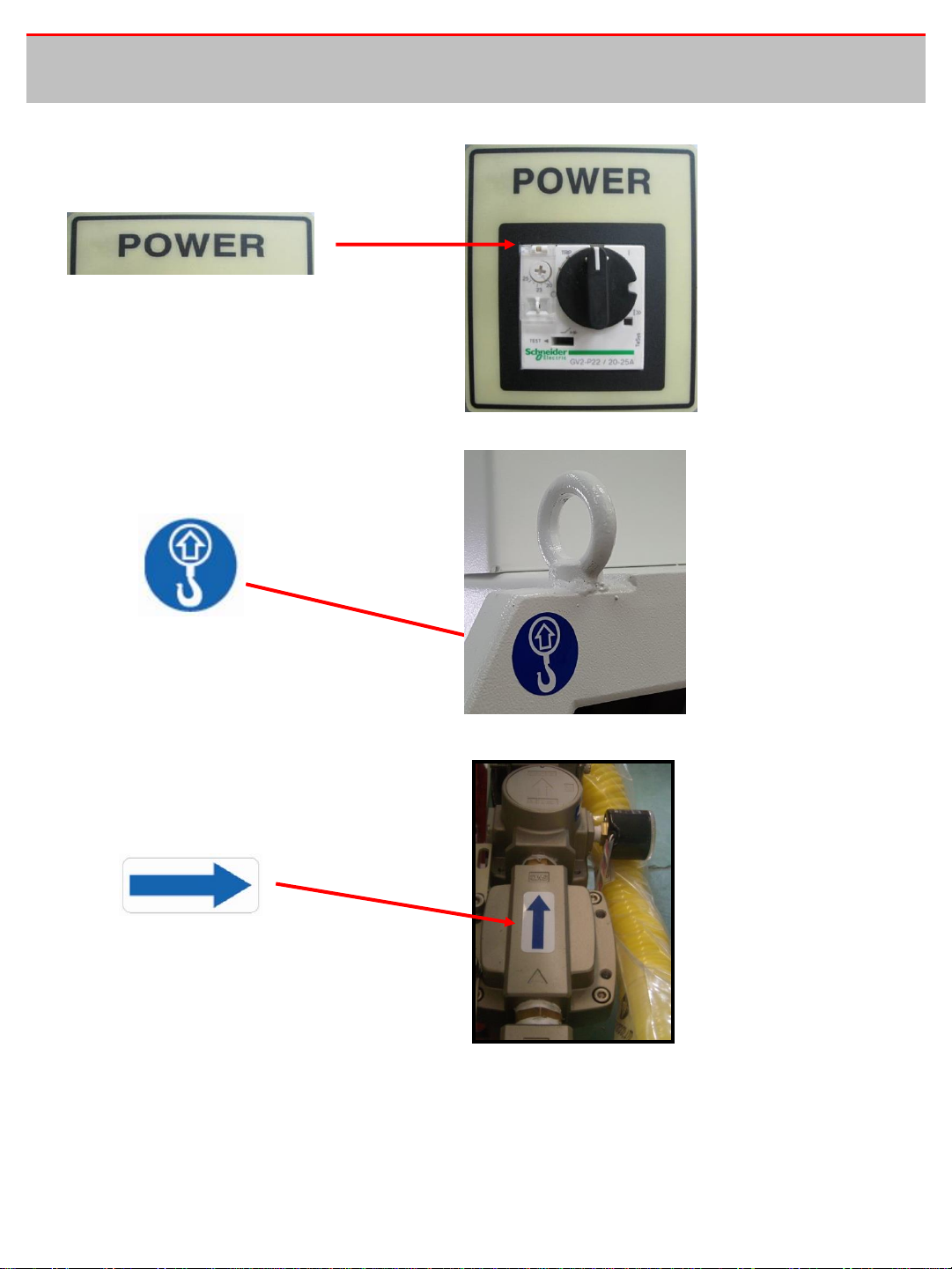

Main circuit breaker

Please use a circuit breaker for the main power.

The system is installed with a circuit breaker but use circuit breaker at the main power supplier to

ensure safety.

5DAEWON GSI