S220(x) User Manual Page 5

TABLE OF CONTENTS

1.0 INTRODUCTION................................................................................................................................6

1.1 Overview of the User Manual.........................................................................................................6

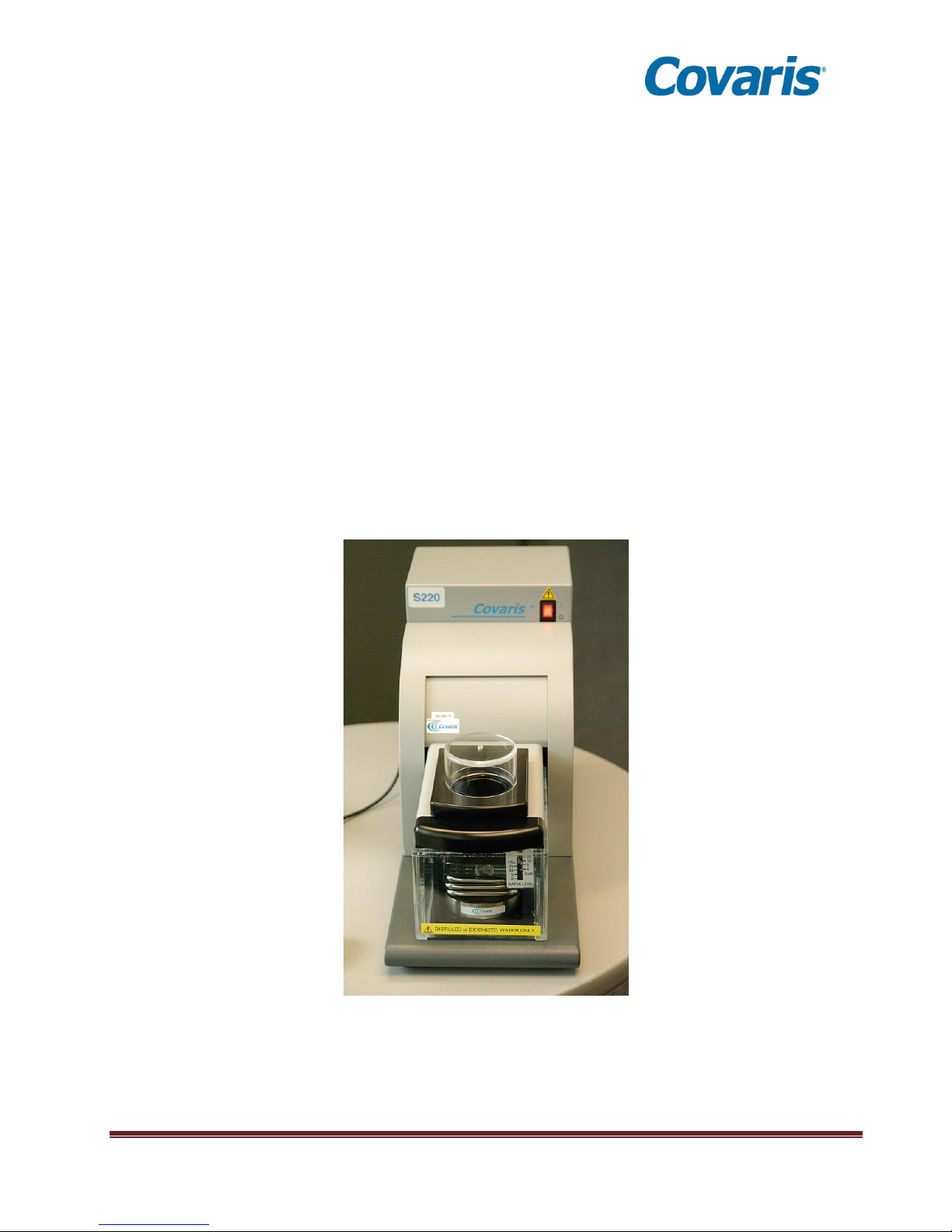

1.2 The S220 and the Covaris Process ...............................................................................................6

2.0 INSTALLATION AND SETUP............................................................................................................7

2.1 Assembly........................................................................................................................................7

2.2 S220 Series Installation .................................................................................................................8

3.0 GETTING STARTED .......................................................................................................................10

3.1 Fill the Water Bath........................................................................................................................10

3.2 Start the System...........................................................................................................................10

3.3 The SonoLab Run Screen - Running a Method...........................................................................11

3.4 System Shutdown ........................................................................................................................14

3.5 Temperature Control....................................................................................................................15

3.6 Degas System..............................................................................................................................15

4.0 SonoLab™ APPLICATION SOFTWARE.........................................................................................16

4.1 Run Screen ..................................................................................................................................16

4.2 Create and Edit Methods .............................................................................................................17

4.3 Temperature Tab..........................................................................................................................21

4.4 Saving Methods in Folders...........................................................................................................22

4.5 History Tab...................................................................................................................................23

4.6 Setup Screen................................................................................................................................23

4.7 Maintenance Screen ....................................................................................................................28

4.8 About Tab.....................................................................................................................................29

5.0 SYSTEM SPECIFICATIONS ...........................................................................................................30

6.0 MAINTENANCE...............................................................................................................................31

6.1 Cooling Air Intake.........................................................................................................................31

6.2 Water Bath ...................................................................................................................................31

6.3 Transducer...................................................................................................................................31

6.4 Safety System..............................................................................................................................31

6.5 Degassing System .......................................................................................................................31

6.6 Cleaning the System....................................................................................................................31

7.0 TROUBLESHOOTING.....................................................................................................................32

Appendix A: Suggested S220 Series IQ / OQ / PQ ....................................................................................34

Appendix B: S Series Site or Transport Preparation...................................................................................40

Appendix C: Installing SonoLab Software, Firmware and Instrument Drivers ............................................41

Appendix D: Recirculating Chiller................................................................................................................46